All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different radiographic inspection requirements for seamless steel pipe?

The different radiographic inspection requirements for seamless steel pipe can vary depending on the specific standards and regulations followed by the industry or country. However, some common radiographic inspection requirements include conducting X-ray or gamma-ray inspections to detect any internal or surface defects in the pipe, such as cracks, porosity, or inclusions. These inspections are typically carried out using specialized equipment and techniques to ensure the quality and integrity of the seamless steel pipe.

How is seamless steel pipe used in the marine industry?

Seamless steel pipe is extensively used in the marine industry for various applications. It is primarily employed in shipbuilding to fabricate hulls, bulkheads, and other structural components due to its high strength and corrosion resistance. Additionally, seamless steel pipes are utilized for constructing pipelines, exhaust systems, and cooling systems on ships, ensuring efficient and reliable operation in harsh marine environments.

Can seamless steel pipes be used for railway infrastructure?

Yes, seamless steel pipes can be used for railway infrastructure. They are commonly used in the construction of railway tracks, bridges, tunnels, and other structures due to their high strength, durability, and resistance to corrosion. Seamless steel pipes provide structural integrity and can efficiently transport fluids, making them suitable for various applications in railway infrastructure.

What are the common uses of seamless steel pipes in the aerospace industry?

Seamless steel pipes are commonly used in the aerospace industry for various applications such as fuel systems, hydraulic systems, and structural components. They are preferred due to their high strength, durability, and resistance to corrosion, making them ideal for carrying fuel and hydraulic fluids under high pressure. Additionally, seamless steel pipes are used in the construction of aircraft frames, wings, and landing gear, providing structural integrity and ensuring the safety of the aircraft.

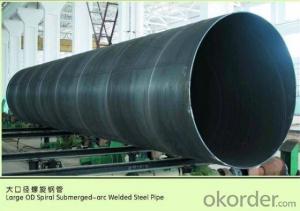

Wholesale Seamless Steel Pipe from supplier in Syria

Our team of experts is dedicated to ensuring that you receive the highest quality Seamless Steel Pipes for your projects in Syria. We work closely with our clients to understand their specific requirements and provide tailored solutions that meet their needs.

With our strong global network, we have access to a wide range of suppliers and manufacturers, allowing us to offer competitive prices and a diverse product range. Whether you need standard or customized Seamless Steel Pipes, we can source them for you.

In addition to our supply capabilities, we also offer a range of value-added services. This includes technical support, where our team of engineers can provide guidance and expertise to ensure that you make the right choices for your projects. We can also assist with logistics and transportation, ensuring that your Seamless Steel Pipes are delivered to your site in a timely and efficient manner.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to provide seamless and efficient services, from the initial inquiry to the final delivery of your Seamless Steel Pipes. Our dedicated sales team is always available to assist you with any queries or requests you may have.

So, whether you are in need of Seamless Steel Pipes for infrastructure projects, construction, or any other industry in Syria, we are here to support you. Contact us today to discuss your requirements and let us provide you with the best solutions for your Seamless Steel Pipe needs.

With our strong global network, we have access to a wide range of suppliers and manufacturers, allowing us to offer competitive prices and a diverse product range. Whether you need standard or customized Seamless Steel Pipes, we can source them for you.

In addition to our supply capabilities, we also offer a range of value-added services. This includes technical support, where our team of engineers can provide guidance and expertise to ensure that you make the right choices for your projects. We can also assist with logistics and transportation, ensuring that your Seamless Steel Pipes are delivered to your site in a timely and efficient manner.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to provide seamless and efficient services, from the initial inquiry to the final delivery of your Seamless Steel Pipes. Our dedicated sales team is always available to assist you with any queries or requests you may have.

So, whether you are in need of Seamless Steel Pipes for infrastructure projects, construction, or any other industry in Syria, we are here to support you. Contact us today to discuss your requirements and let us provide you with the best solutions for your Seamless Steel Pipe needs.