All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

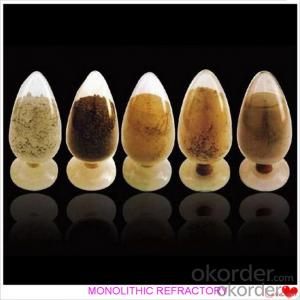

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining ladle teapot spouts?

Yes, monolithic refractories can be used for lining ladle teapot spouts. Monolithic refractories are versatile and can be shaped and formed to fit various applications, including ladle teapot spouts. They provide excellent resistance to high temperatures and thermal shock, making them suitable for lining ladle teapot spouts which are exposed to extreme heat during molten metal pouring.

How are monolithic refractories being used in the pulp and paper industry?

Monolithic refractories are extensively used in the pulp and paper industry for a variety of applications. They are primarily employed in the construction and maintenance of kilns, boilers, furnaces, and other high-temperature equipment used in the production process. Monolithic refractories offer excellent resistance to thermal shock, abrasion, and chemical attack, making them ideal for lining and insulating these critical components. Additionally, their customizable nature allows for easy installation and repair, reducing downtime and ensuring optimal efficiency in the pulp and paper manufacturing process.

How do monolithic refractories provide resistance to molten metal in foundries?

Monolithic refractories provide resistance to molten metal in foundries through their high temperature stability, chemical inertness, and excellent thermal shock resistance. These refractories are made of a single, homogeneous material, which allows for uniformity and consistency in their structure. This uniformity helps to prevent the penetration and absorption of molten metal, ensuring that it remains contained within the mold or furnace. Additionally, monolithic refractories have a dense and compact structure, which minimizes the porosity and permeability of the material, further enhancing its resistance to molten metal.

What are the recommended installation techniques for monolithic refractories in incinerators?

The recommended installation techniques for monolithic refractories in incinerators typically involve proper surface preparation, selection of suitable materials, and careful application methods. It is crucial to ensure that the existing surface is clean and free from contaminants to ensure good adhesion. Additionally, choosing the right refractory material with appropriate thermal conductivity and chemical resistance is important to withstand the harsh conditions of an incinerator. The application techniques may include proper mixing of the refractory material, ensuring thorough wetting, and using suitable tools for installation. It is also essential to follow the manufacturer's guidelines and seek expert advice when required to ensure a successful installation.

How do monolithic refractories handle high-velocity gas flow?

Monolithic refractories are designed to withstand high-velocity gas flow by offering excellent resistance to erosion and thermal shock. They have a dense and homogeneous structure, which helps prevent the gas flow from causing excessive wear and tear on the refractory material. Additionally, monolithic refractories can be tailored to specific applications, allowing for customized solutions that further enhance their ability to handle high-velocity gas flow.

Wholesale Monolithic Refractories from supplier in Pakistan

Our team is ready to assist you with all your Monolithic Refractories needs in Pakistan. Contact us today for sales inquiries, quotations, and technical support. Let's work together to contribute to Pakistan's industrial development and create a prosperous future.

Hot Search

- Monolithic Refractories in Mongolia

- Ceramic Fiber Products in Malawi

- Refractory Bricks in Tuvalu

- Raw Materials For Refractory in Kuwait

- Monolithic Refractories in Bhutan

- Ceramic Fiber Products in Kazakhstan

- Raw Materials For Refractory in Kiribati

- Raw Materials For Refractory in Angola

- Refractory Bricks in Latvia

- Ceramic Fiber Products in Nauru