All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

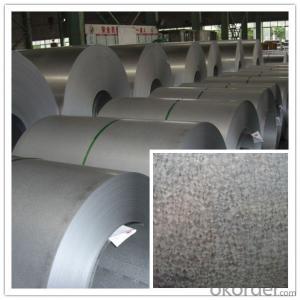

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of vanadium in hot-rolled steel alloys?

Vanadium plays a crucial role in hot-rolled steel alloys as it enhances the strength, toughness, and overall performance of the steel. It helps to refine the grain structure of the steel, making it more resistant to deformation and improving its weldability. Additionally, vanadium promotes the formation of fine carbides which further increase the hardness and wear resistance of the steel.

How is hot rolled steel used in the construction of disaster-resistant structures?

Hot rolled steel is commonly used in the construction of disaster-resistant structures due to its superior strength and durability. Its ability to withstand high temperatures, such as those experienced during fires or explosions, makes it an ideal choice for ensuring the structural integrity of buildings. Additionally, hot rolled steel's resistance to seismic activities and extreme weather conditions, such as hurricanes or earthquakes, makes it a crucial material in constructing disaster-resistant structures. Its versatility and cost-effectiveness further contribute to its widespread use in the construction industry for creating resilient and safe buildings.

How is hot rolled steel different from hot forged steel?

Hot rolled steel and hot forged steel are different in terms of their manufacturing processes and resulting properties.

Hot rolled steel is produced by heating the steel above its recrystallization temperature and then passing it through a series of rollers to achieve the desired shape and thickness. This process results in a steel product with a rough and scaly surface, as well as a larger grain structure. Hot rolled steel is typically used for structural components and is more cost-effective than hot forged steel.

On the other hand, hot forged steel is manufactured by heating the steel to a high temperature and then applying compressive forces to shape it. This process improves the mechanical properties of the steel, such as its strength, toughness, and resistance to fatigue. Hot forged steel has a refined grain structure and a smoother surface finish compared to hot rolled steel. It is commonly used for applications requiring high strength and durability, such as automotive parts, tools, and machinery components.

In summary, the main differences between hot rolled steel and hot forged steel lie in their manufacturing processes, resulting surface finish, grain structure, and mechanical properties. Hot rolled steel is more economical and suitable for structural applications, while hot forged steel offers superior strength and toughness for demanding industrial applications.

How does alloying elements impact hot rolled steel properties?

Alloying elements have a significant impact on the properties of hot rolled steel. These elements can enhance the strength, hardness, and toughness of the steel, as well as improve its resistance to corrosion and wear. By adding alloying elements such as chromium, nickel, and molybdenum, the steel can exhibit improved mechanical properties, making it suitable for various applications in industries like construction, automotive, and manufacturing. Additionally, alloying elements can also influence the grain size and microstructure of the steel, resulting in improved formability and weldability, which are crucial for shaping and joining processes during fabrication.

Wholesale Hot Rolled Steel from supplier in Palau

Whether you are in need of Hot Rolled Steel for construction, manufacturing, or any other application, we have the expertise to meet your specific requirements. Our dedicated team of professionals is committed to delivering high-quality products and excellent customer service.

When you choose us as your Hot Rolled Steel supplier in Palau, you can expect:

1. Reliable Sales: Our experienced sales team is available to assist you throughout the entire procurement process. We will provide you with detailed product information, answer any questions you may have, and guide you towards the best solutions for your project.

2. Competitive Quotations: We understand the importance of competitive pricing in today's market. Our team will work closely with you to offer the most competitive quotations, ensuring that you receive the best value for your investment.

3. Technical Support: Our technical experts are well-versed in Hot Rolled Steel products and their applications. Whether you need assistance in selecting the right grade, size, or specification for your project, we are here to help. Our team can provide technical support and guidance to ensure that you make informed decisions.

4. Timely Delivery: We understand the importance of timely delivery for your projects. With our efficient supply chain management, we ensure that your Hot Rolled Steel products are delivered to your desired location in Palau within the agreed-upon timeframe.

5. Quality Assurance: As a subsidiary of CNBM, we adhere to strict quality control measures to ensure that our Hot Rolled Steel products meet the highest industry standards. We only source from reputable manufacturers, guaranteeing the quality and reliability of our products.

Choosing us as your Hot Rolled Steel supplier in Palau means partnering with a trusted and dependable company. We are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and let us assist you in your Hot Rolled Steel procurement journey.

When you choose us as your Hot Rolled Steel supplier in Palau, you can expect:

1. Reliable Sales: Our experienced sales team is available to assist you throughout the entire procurement process. We will provide you with detailed product information, answer any questions you may have, and guide you towards the best solutions for your project.

2. Competitive Quotations: We understand the importance of competitive pricing in today's market. Our team will work closely with you to offer the most competitive quotations, ensuring that you receive the best value for your investment.

3. Technical Support: Our technical experts are well-versed in Hot Rolled Steel products and their applications. Whether you need assistance in selecting the right grade, size, or specification for your project, we are here to help. Our team can provide technical support and guidance to ensure that you make informed decisions.

4. Timely Delivery: We understand the importance of timely delivery for your projects. With our efficient supply chain management, we ensure that your Hot Rolled Steel products are delivered to your desired location in Palau within the agreed-upon timeframe.

5. Quality Assurance: As a subsidiary of CNBM, we adhere to strict quality control measures to ensure that our Hot Rolled Steel products meet the highest industry standards. We only source from reputable manufacturers, guaranteeing the quality and reliability of our products.

Choosing us as your Hot Rolled Steel supplier in Palau means partnering with a trusted and dependable company. We are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your requirements and let us assist you in your Hot Rolled Steel procurement journey.