All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

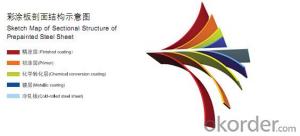

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the sustainability practices and green certifications in the steel strip industry?

In the steel strip industry, there are several sustainability practices and green certifications that companies can adopt to minimize their environmental impact. Some common sustainability practices include using recycled materials in the production process, implementing energy-efficient technologies, reducing greenhouse gas emissions, and managing water and waste responsibly. To showcase their commitment to sustainability, steel strip companies can pursue green certifications such as LEED (Leadership in Energy and Environmental Design) or ISO 14001, which validate their adherence to strict environmental standards and sustainable practices. These certifications not only demonstrate a company's dedication to sustainability but also contribute to building a more environmentally conscious and responsible steel strip industry.

What is the process of tension leveling in steel strip manufacturing?

Tension leveling is a process used in steel strip manufacturing to remove residual stresses and shape defects from the material. It involves passing the steel strip through a series of rolling mills while maintaining a constant tension. This helps to elongate the strip, equalize the thickness, and improve the flatness of the final product. Tension leveling is crucial in achieving high-quality steel strips that are free from distortions and can meet the desired specifications for various industrial applications.

What is the impact of surface finish on the aesthetics of steel strips in architectural applications?

The impact of surface finish on the aesthetics of steel strips in architectural applications is significant. The surface finish of steel strips determines their visual appearance, texture, and overall appeal. A well-executed surface finish can enhance the beauty and elegance of steel strips, making them more visually appealing in architectural designs. It can also contribute to the overall aesthetic of the building, complementing other design elements. Conversely, a poor surface finish can diminish the attractiveness of steel strips and negatively affect the overall aesthetic of the architectural application. Therefore, careful attention to surface finish is crucial in achieving the desired aesthetics in steel strips for architectural applications.

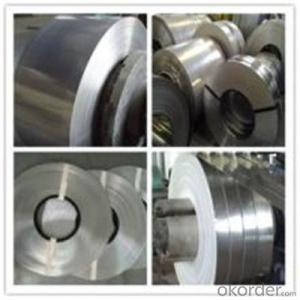

Wholesale Steel Strips from supplier in Philippines

With our strong supply chain network and efficient logistics capabilities, we ensure timely delivery of Steel Strips to any location in the Philippines. Our products are sourced from reputable manufacturers, guaranteeing high-quality standards and superior performance. We offer a wide range of Steel Strips, including hot-rolled, cold-rolled, galvanized, and stainless steel strips, to cater to various applications in industries such as construction, automotive, manufacturing, and more.

In addition to our product offerings, we provide value-added services such as custom cutting and slitting to meet your specific requirements. Our team of experts is available to assist you with technical support and advice, ensuring that you make the right choice for your project. We also offer competitive pricing and flexible payment terms to accommodate your budget and procurement needs.

At CNBM, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional customer service and reliable products. Contact us today to discuss your Steel Strip requirements in the Philippines and experience the CNBM advantage.

In addition to our product offerings, we provide value-added services such as custom cutting and slitting to meet your specific requirements. Our team of experts is available to assist you with technical support and advice, ensuring that you make the right choice for your project. We also offer competitive pricing and flexible payment terms to accommodate your budget and procurement needs.

At CNBM, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by providing exceptional customer service and reliable products. Contact us today to discuss your Steel Strip requirements in the Philippines and experience the CNBM advantage.