glass fiber continuous filament mat (CFM) for pultrusion process

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

- Option:

- 450g/m2

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Introduction

Continuous filament mat is made of continuous fiberglass flament,The filaments are randomly distributed by free fall and then compacted by adhesive bonding. Continuous filament mats suitable for FRP process, for example, pultrusion process, RTM process, flament winding process, molding process and so on.The continuous filament mats are widely used in auto interior, such as sun visor, rear shelf, spare tire cover, fender, refrigerated car box, high voltage resistant insulation for transformers, reinforced profiles, reinforced windows and doors and so on. It also can be used as reinforced materials in GMT, asphalt linoleum, plastic floor geotextile. The reinforced products have high product strength smooth appearance and good moldability.

2.Technical data

| Model No.: | EMS450 | |

| Weight: | 450 grams per sq/m | |

| Width: | up to 2300mm | |

| Moisture: | ≤0.2% | |

| Loss on Ignition: | 4-10 | |

3.Advantages

1.The tensile strength and bending strength are better;

2.Cleaning surface;

3.Excellent chemical stability,heating resistance and well insulation;

4.Anti UV, anti aging, to solve the problem of aging products.

5.Not disperse through the resin tank,The best choice for Pultrusion,

4.Application

5.Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

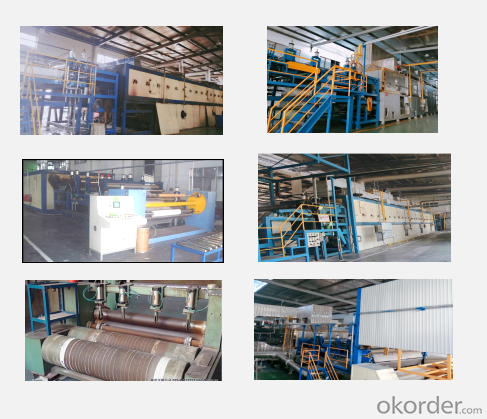

6.Our company:

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our top sales for the trade service.

Question 2: Can I try to get a SAMPLE before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within15-20 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.

- Q:What are the main applications of fiberglass mat tissue?

- Fiberglass mat tissue is a versatile material that finds various applications in industries such as construction, automotive, aerospace, and marine. Some of the main applications of fiberglass mat tissue include: 1. Construction: Fiberglass mat tissue is commonly used in the construction industry for reinforcing and strengthening various building materials such as roofing shingles, wallboards, and cementitious products. It adds tensile strength and durability to the structures, making them more resistant to cracks, water damage, and weathering. 2. Automotive: Fiberglass mat tissue is used in the manufacturing of automotive parts such as dashboards, door panels, and trunk liners. It provides structural integrity, sound insulation, and heat resistance, making the vehicles safer and more comfortable. 3. Aerospace: In the aerospace industry, fiberglass mat tissue is used in the production of lightweight composite materials used in aircraft structures. It helps in reducing the overall weight of the aircraft, improving fuel efficiency, and enhancing its performance. 4. Marine: Fiberglass mat tissue is widely used in boat and shipbuilding. It is used in the construction of hulls, decks, and other components to provide strength, stiffness, and resistance to water and corrosion. Fiberglass mat tissue is preferred over traditional materials like wood due to its lightweight, durability, and low maintenance requirements. 5. Electrical and Electronics: Fiberglass mat tissue is used in electrical insulation applications such as transformer boards, electrical cabinets, and switchgear. It provides excellent dielectric properties, heat resistance, and mechanical strength, ensuring the safety and reliability of electrical equipment. 6. Filtration: Fiberglass mat tissue is used in various filtration applications such as air filters, water filters, and oil filters. It acts as a filtration media, trapping and removing impurities, dust, and particles from the air, water, or oil, thus improving the quality and purity of the filtered substances. Overall, fiberglass mat tissue is a widely used material in numerous industries due to its strength, durability, lightweight, and resistance to various environmental factors. Its versatility makes it an essential component in various applications, contributing to the development of safer, stronger, and more efficient products.

- Q:What is the maximum temperature that fiberglass mat tissue can withstand?

- The specific type of fiberglass material being utilized determines the maximum temperature that fiberglass mat tissue can endure. Typically, fiberglass mat tissues are engineered to withstand temperatures of up to 600 degrees Fahrenheit (315 degrees Celsius). Nevertheless, it should be emphasized that the temperature resistance may fluctuate due to various factors, including material thickness, manufacturing techniques, and the intended usage. For precise information regarding the maximum temperature tolerance of a specific fiberglass mat tissue, it is advised to refer to the manufacturer's specifications or technical data sheets.

- Q:Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

- Q:Can fiberglass mat tissue be used for creating molds?

- No, fiberglass mat tissue cannot be used for creating molds. Fiberglass mat tissue is a thin, lightweight material that is typically used as a reinforcement layer in fiberglass composite applications. It is not designed to be a mold-making material. Instead, materials such as silicone, resin, or plaster are commonly used to create molds due to their ability to capture fine details and provide a smooth surface finish.

- Q:Does fiberglass mat tissue require any special precautions during handling?

- Yes, fiberglass mat tissue does require special precautions during handling. It is important to wear protective gloves, long sleeves, and a mask to prevent skin and respiratory irritation. Additionally, it is recommended to handle fiberglass mat tissue in a well-ventilated area to minimize the inhalation of dust particles.

- Q:Can fiberglass mat tissue be used for reinforcing fiberglass pools?

- Yes, fiberglass mat tissue can be used for reinforcing fiberglass pools. Fiberglass mat tissue is a thin, flexible material that is commonly used in the construction and repair of fiberglass structures, including pools. It is made up of fine glass fibers that are bonded together with a binder. When applied to the surface of a fiberglass pool, the mat tissue provides additional strength and reinforcement, helping to prevent cracks or damage. It is typically applied in conjunction with a fiberglass resin, which acts as an adhesive to bond the mat tissue to the pool surface. Using fiberglass mat tissue for reinforcing fiberglass pools is a common practice and can help to extend the lifespan and durability of the pool.

- Q:What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The expected lifespan of fiberglass mat tissue in power generation applications can vary depending on various factors such as the specific application, environmental conditions, maintenance practices, and quality of the material used. However, fiberglass mat tissue is typically designed to have a long lifespan and can often last for several decades in power generation applications when properly installed and maintained.

- Q:Can fiberglass mat tissue be used for insulation boards?

- Insulation boards can indeed utilize fiberglass mat tissue as a viable option. This lightweight and flexible material consists of delicate glass fibers melded together with a resin. Its outstanding thermal insulation qualities make it an optimal selection for insulation boards. The mat tissue is effortlessly customizable, capable of conforming to various shapes and sizes, thereby facilitating insulation of walls, roofs, floors, and other areas within a structure. Notably, it possesses resistance against moisture, mold, and mildew, ensuring enduring insulation performance. Moreover, fiberglass mat tissue exhibits fire-resistant properties, further bolstering its suitability for insulation applications. In summary, fiberglass mat tissue proves to be an adaptable and efficient material for insulation boards.

- Q:Can fiberglass mat tissue be used for soundproofing?

- Yes, fiberglass mat tissue can be used for soundproofing. Fiberglass is known for its excellent sound absorption properties. When used as a mat or tissue, it can effectively reduce noise transmission by absorbing and dampening sound waves. The porous nature of fiberglass allows it to trap and dissipate sound energy, making it an ideal material for soundproofing applications. Additionally, fiberglass is lightweight, flexible, and easy to install, making it a practical choice for soundproofing projects.

- Q:What is the delamination strength of fiberglass mat tissue?

- The ability of fiberglass mat tissue to resist the separation or detachment of its layers, known as delamination strength, is influenced by various factors. These factors include the quality of the resin used, the thickness and density of the mat, and the manufacturing process. To ensure durability and structural integrity, fiberglass mat tissue is typically designed with a high delamination strength. It is composed of multiple layers of glass fibers held together by a binder or resin. The bonding between these layers is crucial in preventing delamination. Various testing methods, such as the peel test, can determine the delamination strength of fiberglass mat tissue. This test measures the force required to separate the layers and provides valuable information about the adhesive strength between them, helping to assess the material's overall quality. The delamination strength may vary depending on the specific application and requirements. Different industries, such as construction, automotive, marine, and aerospace, may have different delamination strength specifications for their fiberglass mat tissue. Manufacturers typically provide technical data or specifications indicating the delamination strength of their products. It is important to consider external factors that can influence the delamination strength of fiberglass mat tissue, such as exposure to extreme temperatures, moisture, or chemical substances. Proper installation, maintenance, and adherence to recommended usage guidelines are crucial in maintaining the desired delamination strength and overall performance of the material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

glass fiber continuous filament mat (CFM) for pultrusion process

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1300 kg/month

- Option:

- 450g/m2

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords