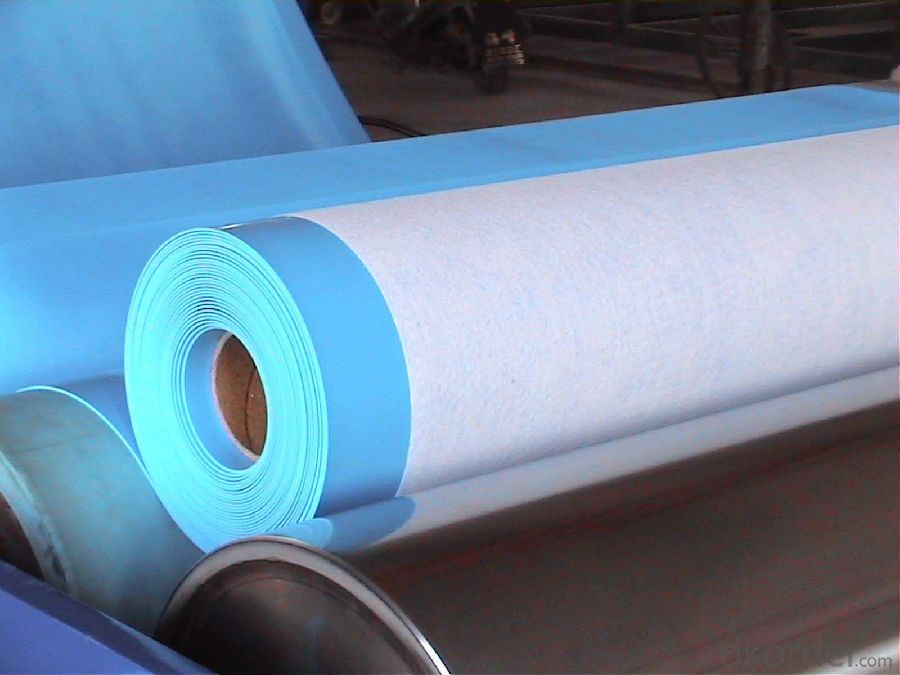

Tpo waterproof Roofing Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of TPO membrane:

Tpo waterproof roofing membrane for sale

1.high breathable membrane

2.market:all over the world

3.resonable price

Main Features of TPO membrane:

- Easy installation with good system integrity, need few accessories

- High tensile and tear strength, puncture resistance

- No plasticizer, heat aging and UV resistance, durable

- Hot-air welding, rapid welding speed, high peel strength (two times of PVC)

-No chlorine, 100% recyclable, environment friendly

- Durable hot-air welding performance and convenient maintainance

- Smooth surface, unfading and stain resistance

Specifications of TPO membrane:

name | type

| The weight of per square meter | thickness | On the surface of the material

| On the surface of the material

|

Slope roofing waterproof adhesive polymer asphalt waterproof cushion layer

| PPPETnon-woven fabrics

| 500g | 0.8mm | Black polypropylene

| Black polypropylene

|

550g | 0.9mm | White polypropylene

|

| ||

600g | 0.9mm | Colored polypropylene

| PE | ||

600g | 0.9mm | PE | PE | ||

700g | 1.0mm | Black polypropylene

| Black polypropylene

| ||

700g | 1.0mm | PE | PE | ||

700g | 1.0mm |

| PE | ||

1100g | 1.2mm | Black polypropylene

| PE | ||

1200g | 1.2mm |

| PE | ||

1500g | 1.4mm |

| PE | ||

1500g | 1.5mm |

|

| ||

2200g | 2.0mm |

|

Applications of TPO membrane:

- Roof construction & steel structure of both industrial and civil engineering

- Underground engineering, such as subways, tunnels, air Raid shelter, etc.

- Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Can a waterproofing membrane be used for railways or train stations?

- Yes, a waterproofing membrane can definitely be used for railways or train stations. Waterproofing membranes are commonly used in various construction projects to protect structures from water damage and ensure their longevity. In the case of railways and train stations, where there is constant exposure to weather elements and potential water infiltration, a waterproofing membrane can play a crucial role in preventing water ingress into the infrastructure. Waterproofing membranes are typically applied to different areas of the railway or train station, such as the underground tunnels, platforms, parking areas, and even the roofs. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the structure and causing damage. By preventing water infiltration, a waterproofing membrane helps to maintain the structural integrity of the railway or train station and extend its lifespan. In addition to protecting against water, waterproofing membranes also provide other benefits such as preventing the growth of mold and mildew, improving energy efficiency by reducing heat loss, and enhancing the overall durability of the structure. They are available in various types, including liquid-applied membranes, sheet membranes, and cementitious coatings, allowing for versatile application depending on the specific needs and requirements of the railway or train station project. Overall, the use of a waterproofing membrane in railways and train stations is highly recommended to ensure the long-term performance and maintenance of these critical infrastructures.

- Q:How does a waterproofing membrane handle settlement cracks?

- A waterproofing membrane is designed to handle settlement cracks by providing a continuous and flexible barrier that prevents water penetration. Settlement cracks occur when the ground beneath a structure shifts or settles, causing the foundation to crack. These cracks can allow water to seep into the building, leading to moisture damage and potential structural issues. When a settlement crack occurs, a waterproofing membrane can be applied to the affected area to create a seamless and watertight seal. The membrane acts as a protective layer that prevents water from entering through the crack and migrating into the building. It also helps to maintain the structural integrity of the foundation by reducing the chances of further cracking and deterioration. The flexibility of the waterproofing membrane is crucial in handling settlement cracks. It can accommodate the movement of the underlying structure without compromising its performance. As the ground settles or shifts, the membrane stretches and contracts, ensuring that the crack remains sealed and the waterproofing system remains intact. Additionally, some waterproofing membranes are equipped with self-healing properties. This means that if a settlement crack does occur, the membrane has the ability to reseal itself to maintain its watertight integrity. This self-healing capability can minimize the need for frequent repairs and maintenance, saving time and costs for property owners. Overall, a waterproofing membrane is an effective solution for handling settlement cracks. It provides a durable and flexible barrier that prevents water infiltration, protects against further damage, and helps to preserve the longevity of the structure.

- Q:Waterproof basement is empty shop or full shop

- Waterproof construction methods are generally reflected in the construction drawings. If not, please consult the designer.

- Q:Can a waterproofing membrane be used on nickel surfaces?

- Yes, a waterproofing membrane can be used on nickel surfaces. The membrane will provide a protective barrier against moisture and prevent water penetration into the nickel surface.

- Q:Are waterproofing membranes resistant to UV rays?

- Yes, waterproofing membranes are typically designed to be resistant to UV rays. They are formulated with additives and coatings that provide protection against the damaging effects of sunlight and ensure long-term durability and performance.

- Q:How to distinguish the degree of sbs waterproofing membrane?

- Method 3: If you do not want to send the laboratory, you can do the test in the refrigerator, as long as the refrigerator can meet the requirements of low temperature on the line. Method to refer to GB 18242 (2008) "elastomer modified asphalt waterproofing membrane". This method can only know the approximate situation of the coil.

- Q:Can a waterproofing membrane be used in food processing or pharmaceutical facilities?

- Yes, a waterproofing membrane can be used in food processing or pharmaceutical facilities. Waterproofing membranes are commonly used in these types of facilities to ensure that the surrounding environment remains dry and free from water damage. They create a protective barrier against moisture, preventing leaks and water penetration. This is particularly important in food processing and pharmaceutical facilities where hygiene and cleanliness are crucial. Waterproofing membranes can be applied to various surfaces such as floors, walls, and ceilings, ensuring that all areas are adequately protected. Additionally, these membranes are often made from materials that are resistant to chemicals and bacteria growth, further enhancing their suitability for use in these sensitive environments. Overall, utilizing a waterproofing membrane in food processing or pharmaceutical facilities is an effective way to maintain a dry and safe environment for the production of quality products.

- Q:Can a waterproofing membrane be used on precast glass surfaces?

- Indeed, precast glass surfaces can benefit from the utilization of a waterproofing membrane. It is common for precast glass surfaces to possess joints and seams that allow water to infiltrate. Applying a waterproofing membrane can effectively establish a protective barrier against water penetration. By doing so, the waterproofing membrane acts as a safeguard, preventing moisture from seeping into the joints and causing potential harm to the precast glass. It is crucial to select a waterproofing membrane specifically designed for glass surfaces and to adhere to the manufacturer's guidelines for proper application. Moreover, it is prudent to perform regular maintenance and inspections to ensure that the waterproofing membrane remains effective over time.

- Q:Can a waterproofing membrane be used for solar panel installations?

- Indeed, the utilization of a waterproofing membrane in solar panel installations is not only possible but highly recommended. It is common practice to incorporate a waterproofing membrane into the installation process in order to safeguard the roof or other surfaces beneath the solar panels from water-related harm. The primary function of a waterproofing membrane is to serve as a barrier, preventing water infiltration into the underlying structure. This, in turn, ensures the integrity and security of the solar panel installation, which is of utmost significance considering their typical placement on rooftops, where they are exposed to various weather conditions. By incorporating a waterproofing membrane, the longevity of the solar panels is prolonged, and any potential issues arising from water are effectively mitigated, thus preserving their optimal performance.

- Q:Can a waterproofing membrane be used for loading docks or ramps?

- Yes, a waterproofing membrane can be used for loading docks or ramps. A waterproofing membrane is designed to protect surfaces from water damage by creating a barrier that prevents water from seeping through. Loading docks and ramps are exposed to various weather conditions and can be prone to water infiltration, which can cause damage over time. Applying a waterproofing membrane to these surfaces can help to prevent water penetration, protecting the structure and increasing its lifespan. Additionally, a waterproofing membrane can also provide added benefits such as slip resistance, protecting against chemical spills, and reducing maintenance costs.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Tpo waterproof Roofing Membrane for Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords