glass wool blanket waterproof thermal insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

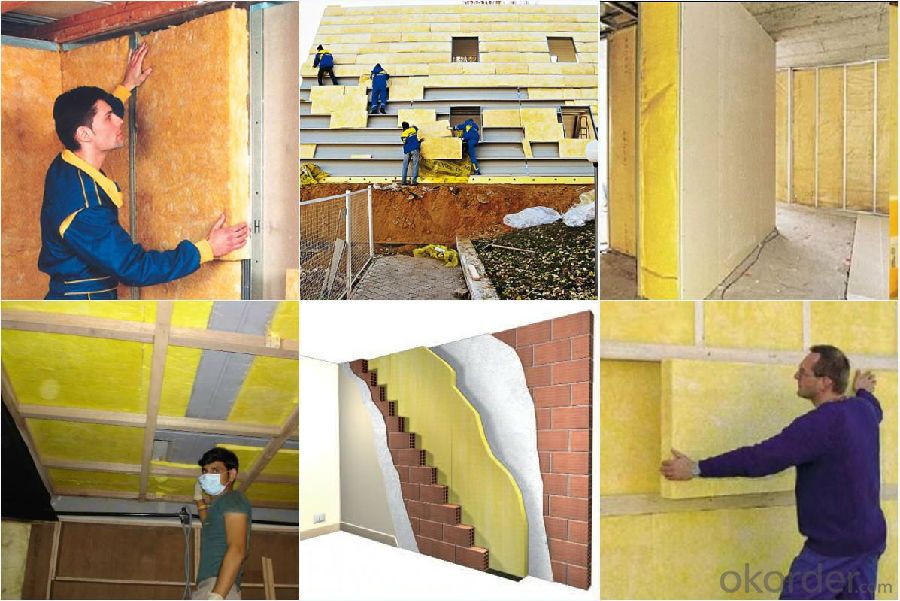

It is widely used for heat insulation and sound absorption in industrial workshops, Prefab houses, Portable cabins, warehouses, public facilities, exhibition centers, shopping malls, and a variety of indoor playgrounds, sports stadiums and etc..

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property. Glass wool blanket, glass wool board, glass wool pipe, which made from glass wool, largely use in construction, chemical, electronic, electricity, metallurgy, energy industry and community with good performance in heat preservation, heat insulation, sound absorption.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

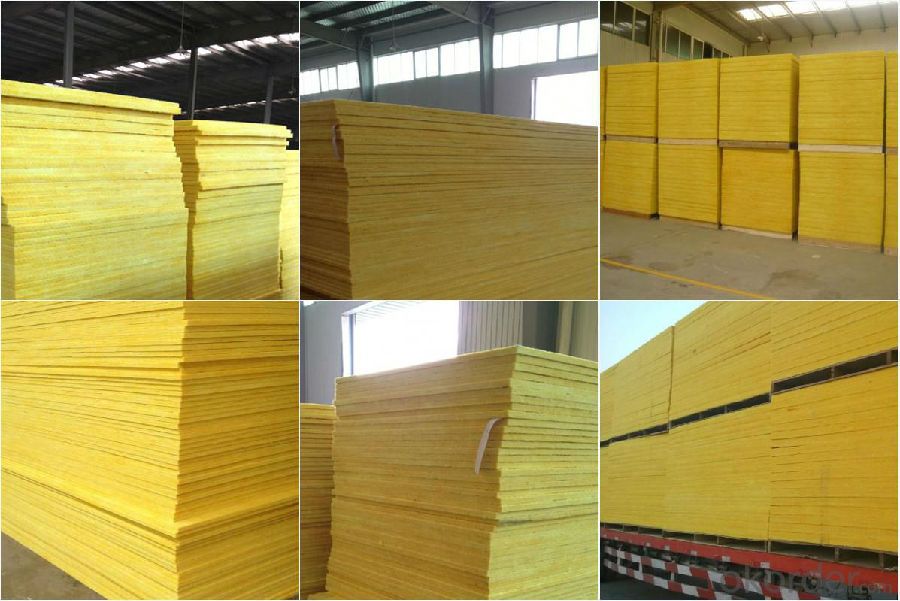

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the potential health hazards associated with working with fiberglass mat tissue?

- There are several potential health hazards that can arise from working with fiberglass mat tissue due to its nature. One major concern is the inhalation of fiberglass particles, which can lead to respiratory problems. When fiberglass is cut or handled, it releases small particles into the air that are easily breathed in. Breathing in these particles for a prolonged period can cause irritation in the throat and lungs, as well as coughing and difficulty breathing. Another health hazard associated with fiberglass mat tissue is skin irritation. The tiny fibers from the material can cause redness, itching, and rashes when they come into contact with the skin. In some cases, prolonged exposure or repeated contact with fiberglass can result in more serious skin conditions like dermatitis. Furthermore, fiberglass mat tissue can also cause irritation and damage to the eyes. If the fibers come into contact with the eyes, they can cause redness, itching, watering, and even scratches on the cornea. It is important to wear appropriate eye protection, like goggles, to prevent any potential eye injuries when working with fiberglass. To minimize these potential health hazards, it is crucial to adhere to safety guidelines and use personal protective equipment (PPE) when working with fiberglass mat tissue. This includes wearing a respirator mask to prevent inhalation of particles, using gloves and protective clothing to reduce skin contact, and wearing safety goggles to protect the eyes. Regular cleaning and good hygiene practices are also essential to minimize any potential health risks associated with fiberglass. It is important to properly clean work areas to remove loose fibers, and to thoroughly wash hands and exposed skin after working with fiberglass. Overall, although working with fiberglass mat tissue can pose potential health hazards, taking appropriate safety precautions and following safety guidelines can greatly reduce the risk of any negative health effects.

- Q:How is fiberglass mat tissue manufactured?

- The production of fiberglass mat tissue is accomplished by utilizing glass fibers and a binder material in a multi-step procedure. Firstly, glass fibers are manufactured by melting raw materials like silica sand, limestone, and soda ash in a furnace. The molten glass is then forced through small holes in a spinneret, resulting in the creation of fine strands of glass fibers. Once the glass fibers are generated, they are gathered and formed into a continuous mat. This is achieved by passing the fibers through a sequence of rollers or air jets that align and compress them into a uniform sheet. At this stage, the mat retains a loose and fragile structure. To provide the fiberglass mat tissue with strength and stability, a binder material is introduced. This binder can be a resin or a mixture of resins and additives. Typically, the binder is sprayed onto the mat, allowing it to permeate and bond with the glass fibers. This process is referred to as wet-laid manufacturing. Following the application of the binder, the fiberglass mat tissue undergoes a curing process. Depending on the specific requirements of the product, this may involve the application of heat, pressure, or both. The purpose of the curing process is to solidify the binder and ensure a secure bond with the glass fibers, resulting in a robust and long-lasting mat. Once the curing process is completed, excess moisture is removed from the fiberglass mat tissue through drying. It is then trimmed and cut to the desired dimensions. Depending on its intended use, the mat may undergo further treatments like surface coatings or laminations to enhance its performance properties. In summary, the manufacturing process of fiberglass mat tissue encompasses the production of glass fibers, the formation of a continuous mat, the addition of a binder material, curing, drying, and final processing. This comprehensive procedure guarantees that the resulting fiberglass mat tissue possesses strength, flexibility, and suitability for a diverse range of applications such as insulation, reinforcement in composites, or roofing materials.

- Q:What is the expected lifespan of fiberglass mat tissue?

- The expected lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, the environment it is exposed to, and how well it is maintained. However, on average, fiberglass mat tissue can have a lifespan of around 20 to 30 years.

- Q:Is fiberglass mat tissue suitable for oil and gas applications?

- Indeed, fiberglass mat tissue proves to be fitting for oil and gas applications. This material, renowned for its lightweight yet robust nature, demonstrates resilience in the face of the demanding conditions that typically arise within the oil and gas sector. Its extraordinary resistance to chemicals, including oil and gas, renders it an optimal selection for endeavors like pipeline insulation, tank lining, and filtration systems. Moreover, fiberglass mat tissue showcases exceptional resistance to moisture absorption, possesses commendable thermal insulation characteristics, and can be effortlessly molded into diverse shapes and forms, thereby establishing itself as a versatile substance suitable for a wide range of oil and gas applications.

- Q:Is fiberglass mat tissue suitable for marine repairs?

- Fiberglass mat tissue is indeed suitable for marine repairs. With its exceptional strength and durability, this versatile material is perfect for fixing and reinforcing different marine structures and components. Notably, fiberglass mat tissue is renowned for its ability to resist water, chemicals, and corrosion, making it indispensable in the marine environment. By utilizing it, hulls, decks, bulkheads, and other boat and ship parts can be repaired, ensuring structural integrity and preventing further harm. Furthermore, applying fiberglass mat tissue is a breeze, as it can be done through various methods like wet lay-up or vacuum bagging. It is no wonder why it is a popular choice for marine repairs.

- Q:What are the different fabric finishes available for fiberglass mat tissue?

- Fiberglass mat tissue offers several fabric finishes, each with its own unique properties and characteristics. Let's explore some of the most common finishes available: 1. Polyester: Widely used in fiberglass mat tissue, polyester fabric finishes provide excellent strength and durability. This finish improves tear resistance and tensile strength. 2. Polypropylene: Known for its high resistance to chemicals and moisture, polypropylene fabric finishes enhance water resistance properties. Ideal for applications where moisture or chemical exposure is a concern. 3. Acrylic: Acrylic fabric finishes offer good heat resistance and flame retardancy. They improve the material's thermal stability and fire resistance, making it suitable for high-temperature or fire-prone environments. 4. Nylon: Renowned for its excellent abrasion resistance and toughness, nylon fabric finishes enhance durability and wear resistance. Perfect for applications involving frequent contact or friction. 5. Polyethylene: With outstanding resistance to moisture and chemicals, polyethylene fabric finishes improve water repellency and chemical resistance. Ideal for outdoor or corrosive environments. 6. Polyurethane: Polyurethane fabric finishes provide flexibility and elasticity to fiberglass mat tissue. They enhance the material's ability to withstand bending and stretching without breaking or tearing. When selecting a fabric finish for fiberglass mat tissue, it's essential to consider specific application requirements. Factors such as strength, durability, water resistance, flame retardancy, abrasion resistance, and chemical resistance should all be taken into account to choose the appropriate finish.

- Q:Can fiberglass mat tissue be used for insulating metal buildings?

- Fiberglass mat tissue is indeed capable of insulating metal buildings. This lightweight and flexible material offers efficient thermal insulation for metal structures. It is frequently applied as a layer between the metal panels and the interior of the building, effectively hindering heat transfer and enhancing energy efficiency. Moreover, fiberglass mat tissue resists moisture and discourages the growth of mold or mildew, making it an excellent option for insulating metal buildings. Nevertheless, it is crucial to ensure correct installation in order to optimize its insulation capabilities and avoid any gaps or air leakage.

- Q:What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The lifespan of fiberglass mat tissue in power generation applications can vary depending on a range of factors, including the specific application, environmental conditions, and maintenance practices. However, fiberglass mat tissue is renowned for its durability and longevity, making it a popular choice in power generation. Typically, fiberglass mat tissue can endure for approximately 20 to 30 years in power generation applications. This longevity is attributed to its exceptional resistance to corrosion, heat, and chemicals, which are commonly encountered in power generation facilities. Additionally, fiberglass mat tissue can withstand high mechanical stress and maintain its structural integrity over extended periods. Nevertheless, it is important to acknowledge that the lifespan of fiberglass mat tissue can be influenced by factors such as exposure to extreme temperatures, humidity, and chemicals, as well as the frequency and quality of maintenance and inspections. Ensuring regular inspections and proper maintenance is crucial for significantly extending the lifespan of fiberglass mat tissue in power generation applications. To determine the specific expected lifespan of fiberglass mat tissue for a particular power generation application and operating conditions, it is advisable to consult with manufacturers and industry experts.

- Q:What about high temperature fiberglass?

- There seems to be a glass fiber cloth, that the head feels the hard plastic feeling, glass cloth drill burr is hard or soft brush to feel it, the heat melts can be adsorbed on the food on it

- Q:What is fiberglass mat tissue?

- Fiberglass mat tissue is a non-woven material made from fine glass fibers that are randomly laid and bonded together. It serves as a reinforcement material in various applications, providing strength, durability, and improved mechanical properties to the final product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

glass wool blanket waterproof thermal insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords