AL+PET+PE+One Layer Bubble Foam For insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. AL+PET+PE+One Layer Bubble Foam For insulation Description:

Reflective insulation material consists of one or two layers bubble or foam that are sandwiched between layers of 99.9% pure aluminum radiant barrier foil . This style can be used in a variety of applications because of its thin, lightweight properties. The bubble layers creates Maximum R value and Vapor barrier , the reflective foil on both sides allow it to reflect 97% of radiant heat away from a structure on the outside and back into a structure from the insides. This is why it works effectively in both hot and cold climates

2.Main Features of the AL+PET+PE+One Layer Bubble Foam For insulation:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

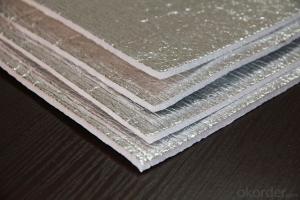

3. AL+PET+PE+One Layer Bubble Foam For insulation Images:

4. AL+PET+PE+One Layer Bubble Foam For insulation Specification:

PROPERTIES Test Data

Thinkness 3.5MM

Weight 256G/M2

Emissivity 0.03-0.04COEF.

Thermal conductivity 0.034W/MO

Apparent Density 120KG/M3

Reflectivity 96-97%

Water Vapour Transmission 0.013G/M2KPA

Corrosion Doesn't generate

Tensile strenght(MD) 16.98Mpa

Tensile strenght(TD) 16.5Mpa

AL+bubble +AL

AL +bubble /bubble +AL

AL+Bubble+ Foam+Bubble+AL

AL+Bubble+PE

AL+EPE +BUBBLE+AL

AL+XPE+Bubble +AL

Note : AL refer to Aluminum Foil,the structure and the surface color of AL can be changed as customer’s requirement

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of Fire Retandent AL Bubble Foam Insulation and is one of the large-scale professional investment Fire Retandent AL Bubble Foam Insulation bases in China. Annually more than 1000 containers of Fire Retandent AL Bubble Foam Insulation are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Glass wool and pef air conditioning insulation material, which one is better?

- So many air-conditioning installation company will choose this new PEF thermal insulation cotton and rubber and plastic thermal insulation material. Generally many companies prefer to use PEF thermal insulation cotton for duct, and rubber and plastic thermal insulation material for water pipes. Productions can be selected according to each person's favor, but we can't only select the cheap products when selecting, and we should choose guaranteed green products.

- Q:how to choose external wall insulation materials for glass wool?

- Glass wool insulation materials insulate medium and low temperature. it belongs to A level fireproof materials and non-combustible. the use temperature of glass wool insulation material is-120 ℃ -400 ℃, used in construction, petrochemical, power, metallurgy and other fields of thermal insulation, sound absorption. Glass wool glass fibers is a man-made mineral fiber, a kind of glass fiber. Glass wool is molten glass that undergoes fibration process, cotton-like material. it is a good shaped inorganic fiber with small volume density, low thermal conductivity, thermal insulation property, sound-absorbing properties, corrosion resistance , chemical stability.

- Q:Sound absorption and sound insulation How is the sound insulation effect of glass wool?

- The sound insulation effect of sound-absorbing and sound-insulating glass wool is very good. Firstly, the quality of wall is good and durable; secondly, the sound insulation effect is very good, mainly because the sound absorption property of glass wool is good, which can cut off external sounds effectively.

- Q:What is the difference between glass wool and rock wool insulation board insulation board ?

- how much is the glass wool insulation board ? From the performance, What are the advantages of glass wool insulation board compared with rock wool insulation board?

- Q:Now what is the latest color steel sandwich board? such as: Foam, stretches, glass wool

- it is better to use rock wool because it is fireproofing and sound insulation.

- Q:What are the industry standards of glass wool and its products?

- Standard: Glass wool belongs to glass fibers and it is a man-made inorganic fibers. Glass wool is made through fibrosis of melten glass and form a cotton-like material. Its chemical composition belongs to glass, and it is a inorganic fiber which has good shape, small volume density, low thermal conductivity coefficient, thermal insulation, good sound-absorbing property, corrosion resistance and chemical stability. So the standard is relatively simple.

- Q:What are the hardnesses of rock wool and glass wool respectively? Are there any requirements on saw blade?

- Almost the same. It should be used universally.

- Q:Which is more suitable for industrial pipe insulation: glass wool or rock wool ?

- Glass wool can only be used in about 260℃, but the highest operating temperature of rock wool is about 600℃. It is easy to construct and install, and can be used for many years with good effect of energy conservation, suitable for small storage tanks and cambered surface with small surface curvature radius and equipments with irregular surface. Rock wool has low heat conductivity coefficient, usually used in thermal insulation places at 450℃. Glass wool has lighter unit weight, lower shot content and higher cost performance ratio than rock wool, so it is widely used in insulation of general buildings and low temperature pipes, building air condition piping insulation and wall sound absorption. While rock wool felt is a quality thermal insulation material with low heat conductivity coefficient. Rock wool felt, with excellent insulation property and low price, is widely used in insulation for high temperature heat pipelines or electrical equipments. While glass wool is usually used in insulation places under 200℃。 Suitable for pipes with medium and large diameter. Fiber has strong toughness. That depends on your need.

- Q:What is the thermal insulation material of glass wool?

- The density is 12kg / m3, isn't it?

- Q:House wall insulation cotton: 12K75mm glass wool+ VR veneering. Is the VR veneering for aluminum foil board?

- it is not aluminum foil. . VR stands for imported white polypropylene. is one of the Owens products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AL+PET+PE+One Layer Bubble Foam For insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords