Glass Wool Pipe Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Pipe Cover for thermal Insulation

1.Structure of Glass wool Pipe Cover for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and blankets. This product is used as insulation and in other applications, like for air filters. It is available through home supply stores and manufacturers can also produce wools for special purposes, like insulation in aircraft, where the standards may be higher for health and safety reasons. Numerous companies make glass wool products along with lines of other insulation materials for a variety of applications.

2.Main Features of Glass wool Pipe Cover for thermal Insulation:

The Glass wool Pipe Cover is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including blankets, boards and pipes. The advantage of this material is numerous: noncombustible, nontoxic, and resistant to corrosion. It has low weight, low thermal conductivity, stable chemical property, low moisture rate and good hydrophobicity. These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

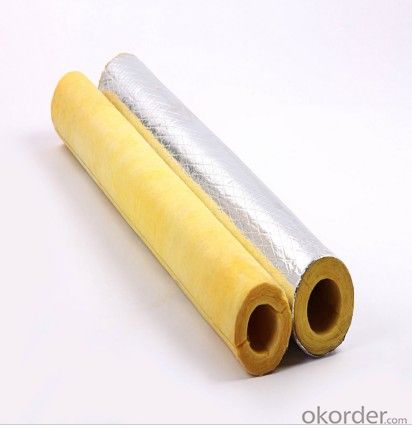

3. Glass wool Pipe Cover for thermal Insulation Images

4. Glass wool Pipe Cover for thermal Insulation Specification

The Glass wool Pipe Cover is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

The Glass wool Pipe Cover with aluminum foil surface has good capability of heat radiation protection.

The Glass wool Pipe Cover with aluminum foil surface has good capability of heat radiation protection.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Note: Product with special specificationcan be made to order.

Both unfaced and faced felts can beprovided.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What is the difference among rock wool board, rock wool and glass wool?

- Rock wool is a kind of mineral wool. It takes natural rocks and minerals and other mateirals as raw materials, and formulates fluffy short fiber. Glass wool belongs to a category of glass fiber, and is a kind of man-made inorganic fiber. Glass wool is a kind of spongiform material shaped by making melten glass fibering, it's chemical content belongs to glass and is a kind of inorganic fiber. It has good molding, small bulk density, low thermal conductivity, good thermal insulation and heat insulation, good sound absorption, corrosion resistance and stable chemical performance.

- Q:Does anyone know about the specifications of formaldehyde-free glass?wool?boards?

- The specifications of formaldehyde-free glass wool board are: 32KG / 50MM, 48KG / 50MM, 80KG / 50MM, 96KG / 25MM, 80KG / 25MM, these are all commonly used now. Hebei kaina Insulation Materials Co., Ltd. is good, which is a large-scale mainstay enterprise of research and development, production and sale of fireproofing and thermal insulation materials. It involves in thermal insulation materials of rock wool, glass wool, phenolic, aluminum silicate, design and construction as well as many other fields. Company products are widely used in many areas and industries around the country for their good quality and cheap price. Hebei kaina Insulation Materials Co., Ltd is located in Dacheng Hebei, the country's largest base of green thermal insulation construction materials. The main products include rock wool products, glass wool products, aluminum silicate products, rubber and plastic products, foam glass thermal insulation board, elevator shaft sound absorption boards.

- Q:Can glass wool be used for external wall insulation?

- Yes, of course, but the thermal insulation effect of glass wool is generally not very good, suggest using XPS board or EPS boards.

- Q:Centrifugal glass wool board and flexible foam rubber insulation, which one is better?

- Glass wool board has good fireproof performance and can endure higher temperature than the rubber material, which is cheap. Rubber material has poor fireproof performance. It has insulation performace no better than other materials.

- Q:The difference between glass wool of 50mm and rock wool.

- Glass wool belongs to one of the glass fiber. machine-made fiber cotton wool molten glass fibrosis cotton material belong to glass fiber. type, bulk density, low thermal conductivity, thermal insualtion, acoustic insualtion, anticorrosion, stable chemical performance. Rockwool is also called mineral wool. Use Guangde Shida rock wool and mineral raw materials to make fluffy short fine fibers. Basalt rock wool, pyroxenite, dolomite, iron ore, bauxite can be used to make matrix fiber by going through high temperature melting process and fibrosis.

- Q:What are the raw materials of centrifugal glass wool?

- The main raw materials of good centrifugal glass wools which are made of industrial chemicals like borax are natural ores like quartz sand, limestone, and dolomite, with some pure alkali.

- Q:What is the construction process of external wall glass?wool?board?

- First, fix the glass wool to the wall with insulation supporting pins to prevent falling. A vapor barrier must be built on the surface of glass wool in order to prevent moisture condensation in the air within the glass wool, which may lead to the decrease of thermal insulation performance. (1) base treatment 1) the vertical control line of the entire surface must be correct, and the verticality of corners must be strictly controlled. 2) clean the floating dust, greasy dirt of release agents of concrete wall surface, masonry wall projections must be removed with a small shovel. 3) clean up the concrete blocks, slags in the joint part of shear walls, then repair again, according to the thickness of ash cake with the proportion of 1:3, and paster with cement mortar.

- Q:What are the requirements for filling the glass wool insulation materials?

- It depends on design requirements, local climate and budget.

- Q:Does rock wool look like glass wool ?

- Glass wool is made through high temperature melting of industrial waste glass, and then making glass into flow by high-speed centrifuge, pulling glass flow into fiber under high temperature and high speed. Rock wool is inorganic fiber made by base materials of fine basalt after high temperature melting in high-speed centrifugation equipment. Glass wool is more economical and environmentally friendly than rock wool.

- Q:Does rock wool refer to the glass wool?

- Rock wool is not glass wool, rock wool's main material is basalt, glass wool material is glass.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Glass Wool Pipe Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords