Good Quality Glass Wool Pipe for Pipe Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass wool Pipe for thermal Insulation

Introduction

As this material has the characters ofwater-proof, anti-corrosion and mildewing-proof, glass wool pipe is good atstopping condensation and freezing of the pipes.

1.Structure of Glass wool Pipe for thermal Insulation:

Glass wool is an industrial product made by spinning glass into a fibrous material that can be packed in mats and pipes. This product is used as insulation and in other applications, like for air filters.

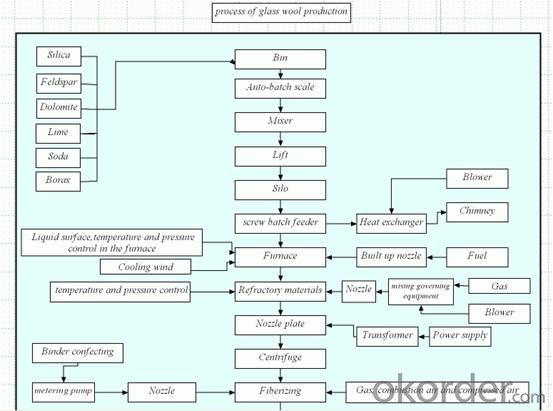

Raw Materials The basic raw materials for fiberglass products are a variety of natural minerals and manufactured chemicals. The major ingredients are silica sand, limestone, and soda ash. Other ingredients may include calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay, among others. Silica sand is used as the glass former, and soda ash and limestone help primarily to lower the melting temperature. Other ingredients are used to improve certain properties, such as borax for chemical resistance. Waste glass, also called cullet, is also used as a raw material. The raw materials must be carefully weighed in exact quantities and thoroughly mixed together (called batching) before being melted into glass.

2.Main Features of Glass wool pipe for thermal Insulation:

The glass wool pipe is applied for large laying area. In the field of insulation materials, we are mainly specializing in Glass wool products, including pipes, boards and pipes.

3. Glass wool pipe for thermal Insulation Images

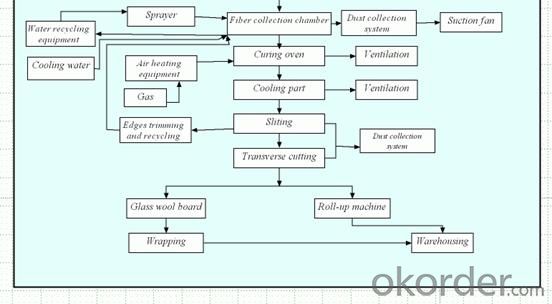

4. Glass wool Processing

5. Glass wool pipe for thermal Insulation Specification

The glass wool pipe is applied for large laying area. Besides the character of thermal insurance, it also has the performances of shock absorption and acoustical isolation, especially for middle or low frequency sound. It also can cancel the noise and improve working environment.

TechnicalData

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm(3/4 inch to 21 inch) |

Length | mm | 1 000,1 200 |

Both unfaced and faced felts can be provided.

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this?

These products have been widely used in heat preservation, thermal insulation and sound absorption in construction, chemical industry, electronic industry, electric power, metallurgy, energy industry, and communication. High density panels laminated with facing can be used for Air-conditioning duct system.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:what is the specifications of glass wool and rock wool shell and tube?

- diameter. The first is the unit weight. ,thickness

- Q:Are there any differences between glass wool and rock wool in terms of appearance, I can't distinguish them, why?

- They have different colors

- Q:What industry does the glass wool belong?

- Glass wool belongs to building materials,is mainly used in steel structure and color steel movable house.

- Q:How can I fix the glass cotton insulation board to the wall?

- The method to fix rock wool insulation boards to the wall: Use adhesion agents to bond rock wool and base wall together, and drive insulation supporting pins. Rock wool external thermal insulation uses rock wool board as insulation layer, and set it outside of the structure layer of external wall to achieve thermal insulation effect of wall. This construction method of composite wall insulation material requirements attached to the solid layer structure. The protective layer outside of insulating layer should have a certain intensity, impact resistance, crack resistance and waterproofness, and have good hotel decoration design. Common characteristics of rock wool wall system incluede the increase of thermal insulation properties of external wall, saving energy consumed for heating, the improvement of wall thermal inertia, and of indoor thermal environment. Compared with other energy-saving wall systems, rock wool system is conducive to the discharge of water vapor inside the wall, generating less internal condensation and dewfall, and the structural layer is drier and warmer. Also, the cost of rock wool system is cheap, it has good fire performance, sound insulation performance.

- Q:what's the price of high temperature resistance glass wool?

- Hello the different thickness and unit weight of the glass wool has different prices , generally a few dollars for each square meter, then if you are from Hebei, there are many companies have this products in Langfang, you can go there to consult. Price depends on how much K you need, that is, the number of density, the current mill price is around 2500 for one ton.

- Q:Which is more effective in retarding fire, rock wool or glass?wool? What is the difference between rock wool and glass wool?

- It is harmful to human body so it is banned.

- Q:Rock wool board and glass?wool?board, which is more harmful to human body?

- Rock wool board, rock wool board has more layers!

- Q:What are the purposes of centrifugal glass wool?

- Use centrifugal injection technique to fiberize the glass in fusion state, then spray filamentary materials made of thermoset resin. Then after the thermosetting deep processing, the centrifugal glass wool can be series products with multiple uses. The internal fibers of centrifugal glass wools are fluffy with many small air voids, which are typical sound-absorbing materials with porosity and good sound absorption performance. Centrifugal glass wool can be made into wall, ceiling, suspended absorber, can absorb a lot of sound energy in the room, reduce the reverberation time and indoor noises.

- Q:Is centrifugal glass wool board suitable for home use?

- A large number of people think that glass wool boards are harmful and that it will cause itch when contacting with the skin. And the effect is not obvious used in the surface, so it is generally used in the wall sandwich. They are harmless for wool boards have been checked, and only those which have passed the national inspection are allowed to be sold for home use. But do not use it in the surface as it is fiber products.

- Q:Is glass wool felt the mineral wool felt?

- No.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good Quality Glass Wool Pipe for Pipe Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords