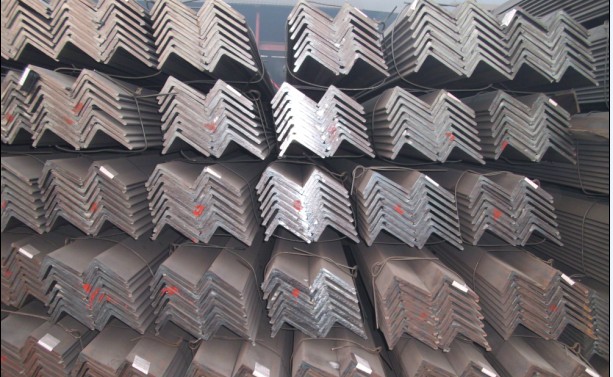

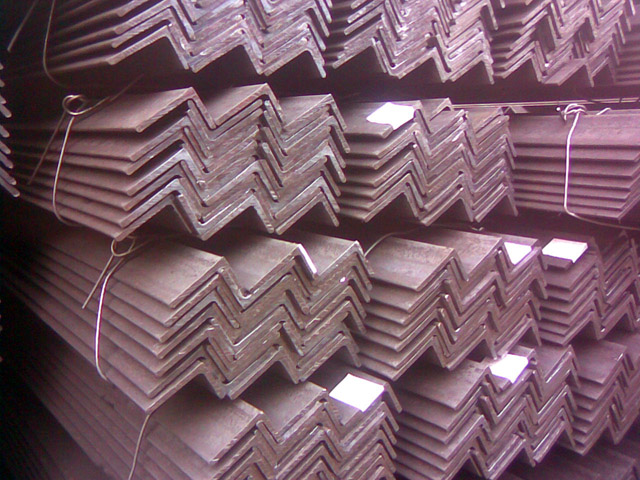

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High alloy stainless steel with excellent high-temperature oxidation resistance and high-temperature strength.Specifications

stainless steel angle

Certification: ISO

Place of Origin: Shanxi, China (Mainland)

Model Number: angle bar

Standard: AISI, ASTM, DIN, GB, JIS

stainless steel angle

| Product | Competitive price stainless steel angle |

| Product classification | Equal Angle Steel & Unequal Angle Steel |

| Production Technics | Hot rolled,cold-bend |

| Productivity | 300,000 Mt/Year |

| Main Material | cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface. hot rolled stainless steel bar: Dia 14.0-150mm,black surface. forged stainless steel bar: Dia 150-350mm, unsmooth surface. |

| Surface treatment | hot dip galvanised or cold dip galvanised |

| Specification | (20*20*2mm)-(200*200*25mm) |

| Theoretical weight per meter | =0.00785*(width+width-thickness)*thickness |

| Application | widely used in Power tower, communication tower, railway, highway, street lamp pole, marine parts, construction steel structure component, handling machinery ,Container frame , warehouse ,reaction tower,the substation ancillary facilities, light industry etc. |

| Length | 6m-12m as you require |

Stainless Steel Angle Bar

1. Material grade:

cold drawn stainless steel bar: Dia 1.0-12.0mm,bright surface.

hot rolled stainless steel bar: Dia 14.0-150mm,black surface.

forged stainless steel bar: Dia 150-350mm, unsmooth surface.

2. Standard: ASTM A276,A484,A564,A581,A582,EN10272,JIS4303,JIS G 431,JIS G 4311,JIS G 4318,stainless steel angle bar

3. Production procedure: raw elements(C,Fe,Ni,Mn,Cr,Cu etc.,)-- smelted ingots by AOD finery-- hot rolled into black surface--pickling into acid liquid--cutting into pieces--checking quality--package

4. Surface: black,pickling,polish, etc ., stainless steel angle bar

5. Common sizes we have large stocks,diameter from 10mm*10mm*2mm-300mm*300mm*20mm

6. Usage:stainless steel angle bar is widely used in chemical, shipping,architecture,machine-made, household products industry, etc.

Definition of stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steelalloy with a minimum of 10.5% to 11% chromium content by mass.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments. It is also called corrosion-resistant steel or CRES when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required.

- Q:Can steel angles be used for bracing?

- Yes, steel angles can be used for bracing. Steel angles are commonly used in construction and engineering projects to provide structural support and reinforcement. They are versatile and can be easily welded or bolted into place, making them suitable for various applications, including bracing. Steel angles are typically strong and rigid, which makes them effective in providing stability and resisting lateral forces. They are often used to brace columns, beams, and other structural elements, enhancing the overall strength and stability of the structure.

- Q:Are steel angles suitable for mezzanine floor construction?

- Indeed, steel angles prove to be suitable for the construction of mezzanine floors. Mezzanine floor construction commonly incorporates steel angles due to their robustness and long-lasting nature. They offer exceptional support and stability, thereby making them an ideal choice for bearing the weight of the mezzanine floor and any additional loads placed upon it. By simply bolting or welding steel angles together, a sturdy framework can be easily created for the mezzanine floor. Moreover, steel angles can be tailored to meet specific design requirements, thereby allowing for flexibility in mezzanine floor construction. In summary, steel angles provide a dependable and cost-effective solution for the construction of mezzanine floors.

- Q:How do steel angles compare to wooden or concrete structural elements?

- Steel angles have several advantages over wooden or concrete structural elements. Firstly, steel angles have a higher strength-to-weight ratio, making them capable of supporting heavier loads with less material. This allows for more efficient structural designs and reduces the overall weight of the structure. Additionally, steel angles have better resistance to fire, pests, and moisture, eliminating concerns related to rotting, termite damage, or decay. Moreover, steel angles provide greater flexibility in terms of design and can be easily modified or extended if needed. Lastly, steel angles offer increased durability and longevity, requiring less maintenance and having a longer lifespan compared to wooden or concrete elements.

- Q:Can steel angles be used in architectural sculptures and installations?

- Architectural sculptures and installations can indeed incorporate steel angles. These angles possess remarkable versatility and are frequently employed in construction due to their robustness and endurance. They can be effortlessly welded, bolted, or affixed using alternative methods, thereby rendering them ideal for the creation of intricate and elaborate structures. Steel angles can be molded and shaped into a myriad of angles and curves, thereby facilitating the realization of imaginative and distinctive designs in architectural sculptures and installations. Moreover, steel angles can be adorned with diverse coatings or paints to heighten their visual allure and safeguard them against corrosion, rendering them an appropriate choice for both indoor and outdoor installations. In conclusion, steel angles provide the essential strength, flexibility, and potential for aesthetic innovation that architectural sculptures and installations require.

- Q:How do you calculate the slenderness ratio of a steel angle?

- The slenderness ratio of a steel angle can be calculated by dividing its length (L) by its radius of gyration (r).

- Q:What are the advantages of using steel angles in manufacturing?

- There are several advantages of using steel angles in manufacturing. Firstly, steel angles provide excellent structural support and stability, making them ideal for various applications such as constructing buildings, bridges, and machinery. Secondly, steel angles have high tensile strength and durability, ensuring long-lasting and reliable performance. Additionally, steel angles are versatile and can be easily customized and fabricated to meet specific design requirements. Lastly, steel angles are cost-effective, readily available, and have a high recyclability rate, making them an environmentally-friendly choice for manufacturers.

- Q:How are steel angles defined?

- Steel angles are defined by their shape and dimensions. They are L-shaped structural members made of steel with two perpendicular legs of equal or unequal lengths. The angle between the legs can range from 90 to 180 degrees, depending on the specific design and application. Steel angles are commonly used in construction and engineering projects to provide structural support, reinforcement, and stability. The dimensions of steel angles are typically specified by their leg length, thickness, and overall length. These dimensions determine the strength, load-bearing capacity, and versatility of the angle, making it suitable for various applications in different industries. Steel angles are also available in various finishes, such as galvanized or painted, to enhance their durability and resistance to corrosion.

- Q:Can steel angles be used for pedestrian bridges or walkways?

- Yes, steel angles can be used for pedestrian bridges or walkways. Steel angles provide strength, stability, and durability, making them suitable for supporting the weight of pedestrians and ensuring the safety of the structure.

- Q:What are the different methods for cutting steel angles?

- There are several different methods for cutting steel angles, including using a bandsaw, a chop saw, an angle grinder, a plasma cutter, or a laser cutter. The choice of method depends on factors such as the thickness of the steel, accuracy requirements, and the desired finish.

- Q:How are steel angles manufactured?

- Hot rolling is the typical method used to manufacture steel angles. This involves heating a steel billet or slab to a high temperature and then passing it through a series of rollers to give it the desired angle shape. Specially designed grooves on the rollers create the distinctive L-shaped cross-section of the steel. Throughout the hot rolling process, the steel undergoes high pressure and strain, which helps shape and form it. The heated steel is passed through the rollers multiple times to achieve the desired dimensions and surface finish. This process also eliminates impurities and enhances the overall quality of the steel. After the steel angles are formed, they are cooled down to stabilize their shape. Cooling can be done using air or water. Once cooled, the angles may undergo additional processing, such as straightening, cutting, drilling, or adding other features according to specific requirements. It is important to note that steel angles can also be manufactured through cold rolling. In this method, the steel is not heated but instead passed through rollers at room temperature. Cold-rolled angles tend to have a smoother surface finish and tighter dimensional tolerances. In summary, the manufacturing process of steel angles involves a combination of heating, rolling, and cooling to shape the steel into the desired angle profile. This process ensures that the angles are strong, durable, and suitable for various applications in construction, manufacturing, and other industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Unequal Stainless Steel 304 Angle Bars or Angle Iron Steel Fabrication

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords