Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

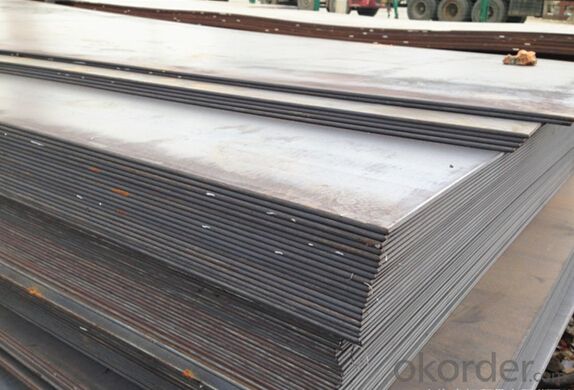

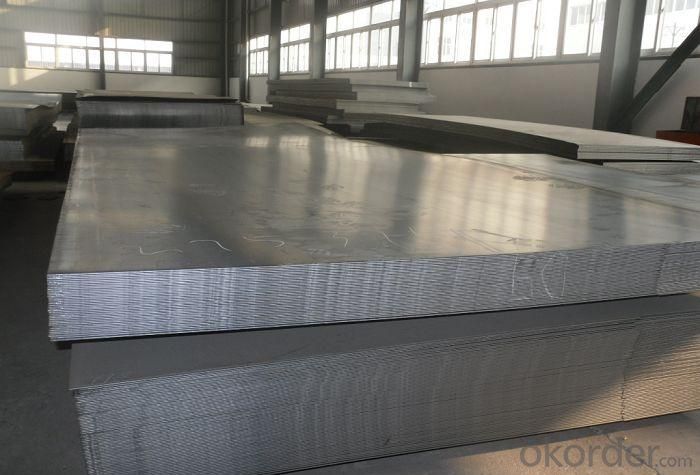

Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

Specification of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery of Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:How is structural steel used in building construction?

- Structural steel is extensively used in building construction due to its high strength and versatility. It serves as the primary framework for buildings, providing support and stability. The steel beams and columns are used to create the skeleton of the structure, spanning large distances and allowing for open floor plans. Additionally, steel is used for various other elements such as stairs, handrails, and roof trusses. Its durability, fire resistance, and ability to withstand extreme weather conditions make it an ideal material for constructing high-rise buildings, industrial facilities, and bridges.

- Q:What are the key characteristics to consider when selecting special steel?

- There are several key considerations to keep in mind when choosing special steel. Firstly, the composition of the steel is of utmost importance. The elements and their proportions within the alloy play a vital role in determining the steel's properties, such as strength, hardness, and resistance to corrosion. It is essential to carefully assess the intended use and select a composition that aligns with the desired performance. Mechanical properties are another critical aspect to consider. Tensile strength, yield strength, ductility, and toughness all determine how the steel will perform under different loads and impacts. Choosing a steel with appropriate mechanical properties for the specific application is crucial. The steel's heat treatment capabilities should also be taken into account. Special steels often undergo various heat treatment processes to enhance their properties. Factors like hardenability, tempering ability, and the ability to maintain hardness at high temperatures are essential factors to consider when selecting special steel. Corrosion resistance is a significant characteristic, particularly if the steel will be exposed to harsh environments or chemicals. Certain special steels are specifically designed to have excellent resistance to corrosion, making them suitable for applications in marine environments, chemical processing plants, or the oil and gas industries. Other characteristics to consider include machinability, weldability, and cost. Machinability refers to how easily the steel can be cut, drilled, or shaped, while weldability determines the steel's ability to be welded without compromising its properties. Cost is an important factor that should align with the project's budget constraints. To summarize, when choosing special steel, it is crucial to consider the composition, mechanical properties, heat treatment capabilities, corrosion resistance, machinability, weldability, and cost. By assessing these key characteristics in relation to the specific application, one can make an informed decision and select the most suitable special steel for the intended purpose.

- Q:How does special steel contribute to the aerospace material cost reduction?

- Special steel contributes to the aerospace material cost reduction by offering superior strength, durability, and corrosion resistance properties. This allows for the design and manufacture of lighter and more fuel-efficient aircraft components. Additionally, special steel's high performance characteristics enable longer service life, reducing maintenance and replacement costs over time.

- Q:What are the different material selection factors for special steel?

- To ensure the desired performance, durability, and cost-effectiveness of the final product, engineers and designers must consider various factors when selecting materials for special steel. Key factors include mechanical properties, corrosion resistance, heat resistance, machinability, weldability, cost, availability, and environmental impact. 1. Mechanical Properties: Special steel must possess the necessary mechanical properties to meet the demands of the specific application. This includes strength, hardness, toughness, fatigue resistance, and wear resistance. 2. Corrosion Resistance: Depending on the intended use, special steel may need to have high corrosion resistance to withstand harsh environments, chemicals, or moisture. This ensures the longevity and reliability of the steel in its intended application. 3. Heat Resistance: Special steel may need to exhibit excellent heat resistance, especially for applications involving high temperatures like aerospace or power generation industries. The material should retain its strength and structural integrity even at elevated temperatures. 4. Machinability: The ease of machining special steel is crucial, especially for applications involving complex shapes or precision components. High machinability allows for efficient manufacturing processes and reduces production costs. 5. Weldability: Special steel selected for applications requiring welding should have good weldability. This ensures that the material can be easily welded without compromising strength or introducing defects. 6. Cost: The cost of the material plays a significant role in material selection. Engineers and designers must balance desired properties with the available budget to achieve optimal cost-effectiveness. 7. Availability: Ensuring a reliable and consistent supply of the chosen special steel is vital to avoid production delays or interruptions. 8. Environmental Impact: The environmental impact of the material should be evaluated, considering factors such as energy consumption during production, recyclability, and the use of sustainable raw materials. Opting for eco-friendly materials aligns with sustainable practices and regulations. By carefully considering these material selection factors, engineers and designers can choose the most suitable special steel for their specific application, ensuring optimal performance, durability, and cost-efficiency.

- Q:How does special steel perform in high-speed machining operations?

- Special steel is specifically designed to withstand high-speed machining operations with exceptional performance. Its unique composition and properties, including high hardness, heat resistance, and wear resistance, allow it to maintain its strength and durability even under extreme cutting speeds and temperatures. This enables special steel to deliver superior machining efficiency, precision, and surface finish, making it an ideal choice for high-speed machining operations.

- Q:How is special steel heat treated?

- Special steel is heat treated using a combination of heating and cooling processes to enhance its mechanical properties. This typically involves heating the steel to a specific temperature and holding it there for a designated period of time, followed by rapid cooling or quenching. The heat treatment process can vary depending on the desired outcome, such as improving hardness, strength, or toughness, and may also involve additional steps like tempering or annealing.

- Q:What are the different nuclear grades of special steel?

- There are several nuclear grades of special steel, including but not limited to A508 Class 1, A533 Type B Class 1, A533 Type B Class 2, A508 Class 2, A533 Type C Class 1, A508 Class 3, and A533 Type C Class 2. These grades are specifically designed to meet the stringent requirements of nuclear power plant applications, ensuring high strength, resistance to radiation damage, and excellent fracture toughness.

- Q:Can special steel be used in the solar panel manufacturing industry?

- Yes, special steel can be used in the solar panel manufacturing industry. It is commonly used for the frames and supports of solar panels due to its high strength, durability, and corrosion resistance properties. Special steel helps to ensure the structural integrity and longevity of solar panels, making it an essential material in the industry.

- Q:What are the different methods of improving the creep resistance of special steel?

- There are several methods of improving the creep resistance of special steel, which are designed to enhance its ability to withstand long-term exposure to high temperatures and constant stress. Some of the methods commonly employed include: 1. Alloying: Special steel can be alloyed with specific elements to enhance its creep resistance. The addition of elements such as chromium, molybdenum, tungsten, and vanadium can significantly improve the material's ability to resist creep deformation. These alloying elements form strong carbides or intermetallic compounds, which impede the movement of dislocations and enhance the material's strength and resistance to creep. 2. Heat treatment: Precise heat treatment techniques can be employed to improve the creep resistance of special steel. Processes such as quenching and tempering, annealing, and normalizing can alter the steel's microstructure, leading to the formation of fine-grained and homogeneous structures that offer improved creep resistance. Heat treatment also helps in relieving residual stresses and improving the material's overall strength. 3. Grain refinement: Special steel can be subjected to processes that refine its grain structure, thereby enhancing its creep resistance. Techniques such as grain size reduction through controlled rolling, recrystallization, and severe plastic deformation can lead to the formation of smaller and more uniform grains. This refined microstructure hinders dislocation movement and improves the material's resistance to creep deformation. 4. Precipitation hardening: Special steel can be subjected to precipitation hardening methods, where the material is heated and then rapidly cooled to induce the formation of fine precipitates. These precipitates act as barriers to dislocation movement, improving the material's strength and creep resistance. 5. Surface modification: Special steel can be treated with surface modification techniques to increase its creep resistance. Methods such as shot peening, laser surface melting, and surface coatings can improve the surface integrity, reduce surface roughness, and introduce compressive residual stresses, all of which contribute to enhanced creep resistance. It is important to note that the selection and combination of these methods depend on the specific requirements of the application and the type of special steel being used. The aim is to optimize the material's microstructure, chemical composition, and surface characteristics to achieve the desired creep resistance and ensure long-term performance at elevated temperatures.

- Q:What is the role of special steel in the automotive industry?

- Special steel plays a crucial role in the automotive industry by providing strength, durability, and resistance to wear and corrosion for various components. It is used in the production of engine parts, chassis components, transmission systems, and safety features, ensuring enhanced performance, reliability, and safety in vehicles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Plate_Sheet Weight Grade A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords