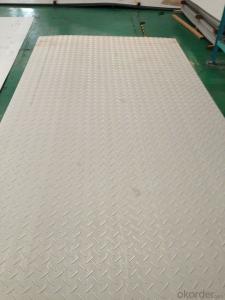

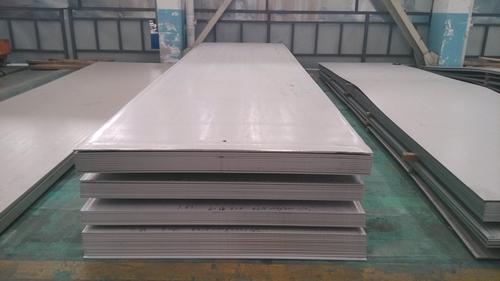

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Stainless steel 304 sheet

Company advantage of stainless steel:

-Top Equipments, Leading In The Industry.

- Professional Team, Leading Innovation.

- Huge Supply Capacity Advantage, Timely and Effective Delivery.

- Modern Logistic, Fact and Convenient.

- Precise Manufacturing, Exquisite Products.

- Serve People, Create Value.

- Dimensional Network, Powerful Expansion.

Product Information of stainless steel sheet:

- Q:Water and electricity thin wall stainless steel tube 304 material delta 2 what does that mean?

- High temperature resistance is also good, the general use of temperature limit is less than 650 degrees centigrade. 304 stainless steel has excellent stainless steel corrosion resistance and better intergranular corrosion resistance. Delta 2 indicates wall thickness of 2 mm

- Q:Can stainless steel pipes be used for natural gas systems?

- Yes, stainless steel pipes can be used for natural gas systems. Stainless steel is highly resistant to corrosion and can withstand high pressure and temperature, making it a suitable material for transporting natural gas. The smooth inner surface of stainless steel pipes also allows for efficient gas flow, minimizing the risk of blockages or obstructions. However, it is important to ensure that the stainless steel pipes used meet the specific standards and codes required for natural gas systems to ensure safety and compliance.

- Q:What is the welding of stainless steel?

- If batch welding, it is recommended to use laser welding, welding heat affected area is small, weld appearance, speed, more suitable for thin plate,

- Q:What is the difference between seamless and hot-finished stainless steel pipes?

- Seamless and hot-finished stainless steel pipes are both used in various industrial applications, but they have some key differences. The main difference between seamless and hot-finished stainless steel pipes lies in their manufacturing process. Seamless pipes are made by piercing a solid steel billet to form a hollow tube without any seams or joints. This process ensures a consistent wall thickness throughout the pipe and a smooth interior surface. On the other hand, hot-finished pipes are created by heating a solid billet and then rolling it to form a tube shape. This rolling process can result in a seam or weld line along the length of the pipe. Another significant difference between seamless and hot-finished stainless steel pipes is their dimensional accuracy and surface finish. Seamless pipes are known for their high dimensional accuracy and excellent surface finish, making them suitable for applications where a precise fit and smooth flow are critical, such as in the pharmaceutical or food processing industries. Hot-finished pipes, although generally not as precise in terms of dimensions and surface finish, are more cost-effective and widely used in applications where tight tolerances are not required, such as in structural or construction projects. In terms of strength and durability, both seamless and hot-finished stainless steel pipes offer excellent performance. However, seamless pipes tend to have higher strength due to their manufacturing process, as there are no weak points or potential areas of failure like welded seams. This makes seamless pipes preferred in applications that require high pressure or corrosion resistance, such as in oil and gas pipelines or chemical processing plants. In summary, the main differences between seamless and hot-finished stainless steel pipes lie in their manufacturing process, dimensional accuracy, surface finish, and strength. Seamless pipes are produced without any seams or welds, resulting in superior dimensional accuracy and surface finish, making them suitable for precise applications. On the other hand, hot-finished pipes are more cost-effective and widely used in applications where tight tolerances are not crucial. Both types of pipes offer excellent strength and durability, but seamless pipes are generally preferred in high-pressure or corrosive environments.

- Q:Comparison of ring type connection and argon arc welding of stainless steel pipe

- Characteristics of argon arc welding of stainless steel pipe:1. Permanent structure, reliable quality;2. Reduce the number of parts used;3. The construction technology is relatively complicated.

- Q:Are stainless steel pipes suitable for hydraulic applications?

- Yes, stainless steel pipes are suitable for hydraulic applications. They offer excellent corrosion resistance and durability, making them ideal for use in hydraulic systems where fluid flow and pressure are involved. Additionally, stainless steel pipes can handle high temperatures and are resistant to cracking, making them a reliable choice for hydraulic applications.

- Q:Can stainless steel pipes be insulated with ceramic?

- Ceramic can indeed be used to insulate stainless steel pipes. It is commonly utilized in industrial settings that involve high temperatures. Ceramic insulation offers exceptional heat resistance and thermal insulation properties, making it an excellent choice. It can withstand extreme temperatures and effectively reduces heat transfer. Various industries utilize ceramic insulation to insulate pipes, tanks, furnaces, and other equipment. When applied to stainless steel pipes, ceramic insulation helps maintain the fluid's temperature, preventing heat loss or gain. Additionally, it provides protection against corrosion and mechanical damage. In summary, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

- Q:Can stainless steel pipes be engraved?

- Yes, stainless steel pipes can be engraved. Engraving is a process that involves etching or carving designs, patterns, or text onto the surface of an object. Stainless steel is a versatile material that can be engraved using various methods, such as laser engraving, rotary engraving, or hand engraving. Laser engraving is particularly popular for stainless steel pipes as it provides precise and permanent markings. The engraved design or text can enhance the aesthetic appeal of the pipes and also serve functional purposes, such as identification or branding. However, it is important to note that the depth and quality of the engraving may vary depending on the type and grade of stainless steel used.

- Q:What does "stainless steel pipe" DN mean?

- DN is nominal diameter, nominal diameter (or nominal diameter), that is, all kinds of pipe and pipe accessories of universal caliber. The pipes of the same nominal diameter can be connected with each other and are interchangeable. It is not the outer diameter or inner diameter of the pipe in actual sense, although its value is close to or equal to the diameter of the pipe;

- Q:Can stainless steel pipes be used for high-temperature applications?

- Indeed, high-temperature applications can employ stainless steel pipes. Renowned for its exceptional heat resistance properties, stainless steel proves suitable for diverse industries necessitating pipes that endure extreme temperatures. The elevated quantity of chromium in stainless steel facilitates the creation of a safeguarding layer of chromium oxide on the surface, thus averting oxidation and corrosion even under heightened temperatures. Furthermore, stainless steel pipes possess superior strength, commendable mechanical attributes, and resistance to thermal expansion and contraction, rendering them an excellent choice for high-temperature applications encompassing power generation, chemical processing, oil and gas, and numerous other sectors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel 304 sheet with top quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords