PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of PVDF Coating Aluminum for Building Decorations Description:

Aluminium coated sheetl/ aluminium colour shee is PE (polyester) coating: high molecular polymer as monomer and addition of alkyd, is a UV-resistant coating. It can be classified either as matt or glossy according to your needs. The compact molecule structure makes the point surface luster and smooth, which assures good printing on the panels’ surface.

Aluminium Coated Sheet is widely and mainly used for building decoration, such as ACP, aluminum, ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliances, food package (such as pop can cover & ring-pull), furniture ect.

2.Main Features of PVDF Coating Aluminum for Building Decorations:

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

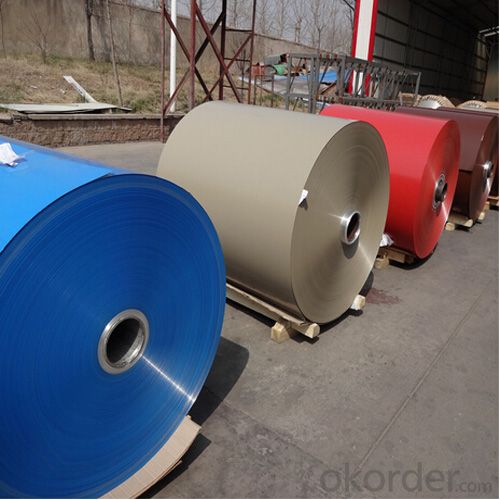

3. PVDF Coating Aluminum for Building Decorations Images:

4. PVDF Coating Aluminum for Building Decorations Specification:

Grade | 1050,1060,1070, 1100, 1200, 2024,3003, 3004,3005, 3105, 5005,5052 5182,5754,8011 etc. |

Thickness | 0.1~1.5mm |

Width | 100~2200mm |

Application | Decorative Materials |

Surface Treatment | Coated |

Temper | O - H112 |

Hardness | More than 2H |

Yield (≥ MPa) | 160 |

Temper | O - H112 |

Ultimate Strength (≥ MPa) | 175 |

Elongation (≥ %) | 6 |

Packing material | Moisture-proof agent, steel tape bundle, wooden pallet, brown paper |

Method | Vertical( eye to sky) or horizontal( eye to wall) |

Standard spec | 1000mm xC, 1200mm xC etc |

Shipping | Container Loading or Bulk Pack |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a commonly used material for heat transfer in such systems due to its excellent thermal conductivity and corrosion resistance.

- Q:How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage through a variety of methods. One common method is applying a protective coating on the surface of the coils. This coating acts as a barrier, preventing oxygen from coming into contact with the aluminum and causing oxidation. The coating can be a thin layer of oil or a special protective film. Another method is storing the coils in a controlled environment with low humidity. Moisture in the air can accelerate the oxidation process, so by keeping the coils in a dry environment, the risk of oxidation is reduced. Additionally, aluminum coils can be stored in airtight packaging, such as plastic wraps or vacuum-sealed bags. This further minimizes the exposure to oxygen, preventing oxidation. It is also important to handle the coils with care during storage to avoid any damage that could potentially expose the aluminum to the air. Proper packaging and stacking techniques are crucial to ensure the coils remain protected. Overall, a combination of protective coatings, controlled environments, and proper handling techniques are employed to safeguard aluminum coils against oxidation during storage.

- Q:How do aluminum coils contribute to sustainable building practices?

- Aluminum coils contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, which means that coils made from aluminum can be easily recycled at the end of their lifespan, reducing waste and conserving resources. Additionally, aluminum is lightweight yet durable, making it an ideal choice for construction materials. This lightweight characteristic reduces the need for heavy structural support, resulting in reduced energy consumption during transportation and installation. Moreover, aluminum coils have excellent corrosion resistance, allowing them to withstand harsh weather conditions and prolonging their lifespan, thus reducing the frequency of replacements and minimizing environmental impact. Ultimately, the use of aluminum coils in sustainable building practices helps conserve resources, reduce energy consumption, and promote a circular economy.

- Q:Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q:What is the difference between hot rolled and cold rolled aluminum coils?

- The main difference between hot rolled and cold rolled aluminum coils lies in their production process and the resulting properties of the final product. Hot rolled aluminum coils are produced by heating aluminum ingots above their recrystallization temperature, typically around 450°C (842°F), and then rolling them through a series of rollers to reduce their thickness and shape them into coils. This process allows for quick production and the ability to produce larger coils. However, hot rolling can lead to a less precise and less smooth surface finish, with potential for surface defects and oxidation. On the other hand, cold rolled aluminum coils are produced by further processing hot rolled coils. The hot rolled coils are first pickled, or chemically treated, to remove any mill scale or impurities. They are then cold rolled, which involves passing them through a series of rollers at room temperature. This process results in a more precise and smoother surface finish, with excellent dimensional accuracy and tighter tolerances. Cold rolling also increases the strength and hardness of the aluminum, making it more suitable for certain applications. In terms of properties, hot rolled aluminum coils generally have lower strength and hardness compared to cold rolled coils. They also have a higher likelihood of surface defects and oxidation due to the high temperature involved in the production process. Cold rolled aluminum coils, on the other hand, exhibit higher strength and hardness, as well as better surface finish and dimensional accuracy. These properties make cold rolled aluminum coils more suitable for applications that require higher quality and precision. Overall, the choice between hot rolled and cold rolled aluminum coils depends on the specific requirements of the end-use application. Hot rolled coils are often used in applications where speed and cost-effectiveness are prioritized, while cold rolled coils are preferred for applications that demand higher quality, precision, and strength.

- Q:How are aluminum coils protected during shipping?

- Aluminum coils are protected during shipping through various methods to ensure their safety and prevent any damage. One common method is the use of protective packaging materials such as bubble wrap, foam, or corrugated cardboard. These materials are used to wrap the coils and create a cushioning effect, absorbing any impact or vibration that may occur during transportation. In addition to protective packaging materials, aluminum coils are often placed in sturdy shipping containers or crates. These containers are designed to provide extra security and stability during transit, minimizing the risk of the coils being jostled or bumped. Moreover, in some cases, aluminum coils are secured with strapping or banding to keep them in place and prevent shifting or movement during transportation. This helps to maintain the integrity of the coils and minimize the risk of damage caused by rubbing against other objects. Furthermore, shipping companies may also use air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This further reduces movement and provides an additional layer of protection for the coils. Overall, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their destination.

- Q:What are the potential applications of pre-painted aluminum coils?

- Pre-painted aluminum coils have a wide range of potential applications due to their versatility and durability. One potential application is in the construction industry, where pre-painted aluminum coils can be used for roofing and cladding. The pre-painted coating provides an attractive and protective finish, making it ideal for both residential and commercial buildings. Additionally, aluminum is lightweight, which makes it easier to install and transport. Another potential application is in the manufacturing of appliances and electronics. Pre-painted aluminum coils can be used to create outer casings for various appliances, such as refrigerators, ovens, and air conditioners. The coating provides a smooth and aesthetically pleasing finish, while the aluminum itself offers excellent heat dissipation properties. Pre-painted aluminum coils also find applications in the automotive industry. The durable coating helps protect the surface of the vehicle from scratches, UV rays, and corrosion. Additionally, aluminum is lightweight, which can contribute to fuel efficiency and improved performance. In the signage industry, pre-painted aluminum coils are commonly used for outdoor and indoor signage. The coating provides a long-lasting and vibrant finish, making it suitable for a variety of signage applications, such as billboards, store signs, and traffic signs. Furthermore, pre-painted aluminum coils can be employed in the manufacturing of furniture and fixtures. The coating adds a decorative touch to furniture pieces, while the aluminum provides strength and stability. This makes pre-painted aluminum coils suitable for items such as cabinets, shelves, and decorative panels. Overall, the potential applications of pre-painted aluminum coils are vast and diverse. Their versatility, durability, and attractive finish make them suitable for various industries, including construction, manufacturing, automotive, signage, and furniture.

- Q:How are aluminum coils used in rainwater harvesting systems?

- Rainwater harvesting systems commonly use aluminum coils due to their durability and effective heat transfer properties. These coils are typically installed inside rainwater storage tanks and connected to a heat exchanger system. The main purpose of aluminum coils in rainwater harvesting systems is to facilitate the heating or cooling of stored rainwater, depending on its intended use. For example, if the harvested rainwater is meant for domestic use like showers or laundry, the aluminum coils can effectively heat the water to the desired temperature. Conversely, if the harvested rainwater is intended for cooling purposes such as air conditioning or industrial processes, the coils can also efficiently cool the water. The design of the aluminum coils maximizes the surface area exposed to the rainwater, enabling efficient heat transfer. This allows the coils to quickly absorb or release heat based on the system's requirements. Aluminum is chosen as the material for these coils due to its high thermal conductivity, corrosion resistance, and lightweight nature. Furthermore, the coils also aid in preventing the growth of bacteria and algae within the rainwater storage tanks. Aluminum possesses natural antimicrobial properties that hinder the growth of these organisms, ensuring that the collected rainwater remains clean and safe for use. In summary, aluminum coils are essential components in rainwater harvesting systems as they enhance the usability of collected rainwater through efficient heat transfer and maintenance of water quality.

- Q:Which is better composite or aluminum, and what are some main differences between the two?

- This Site Might Help You. RE: Composite vs Aluminum baseball bats? Which is better composite or aluminum, and what are some main differences between the two?

- Q:Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Coating Aluminum for Building Decorations

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords