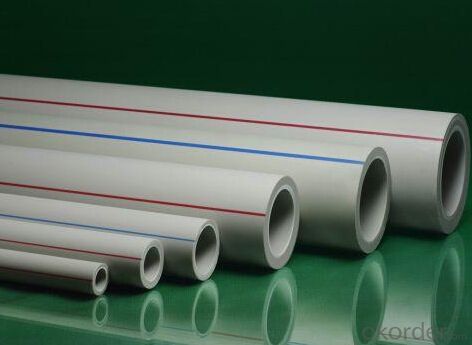

PPR pipe and fittings used in Industrial fields 2017 new

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Products

1.It is used in industrial fields

2. Beauty appearance.

3.Thermal insulation and energy saving.

4. Easy installation

5.excellent heat resistance and pressure resistance

size

1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa | |

Outer | Wall | Wall | Wall | Wall |

Diameter | Thickness | Thickness | Thickness | Thickness |

dn(mm) | en (mm) | en (mm) | en (mm) | en (mm) |

20 | 2.0 | 2.3 | 2.8 | 3.4 |

25 | 2.3 | 2.8 | 3.5 | 4.2 |

32 | 2.9 | 3.6 | 4.4 | 5.4 |

40 | 3.7 | 4.5 | 5.5 | 6.7 |

50 | 4.6 | 5.6 | 6.9 | 8.3 |

63 | 5.8 | 7.1 | 8.6 | 10.5 |

75 | 6.8 | 8.4 | 10.1 | 12.5 |

90 | 8.2 | 10.1 | 12.3 | 15.0 |

110 | 10 | 12.3 | 15.1 | 18.3 |

160 | 14.6 | 17.9 | 21.9 | 26.6 |

Specification

1.Material: | PPR |

2.Color: | White, Gray, Green, or as you required. |

3.Size: | 20-110mm |

4.Logo: | CMAX or Customized |

5.MOQ | 500pcs |

6.Samples Time: | (1) 4-5days-If you want to customize your logo. |

(2) 1day-For our existing samples for reference. | |

7.OEM Accepted | Yes |

8.Certification available: | Yes |

9.Packing Details: | Weaving Bag |

10.Production Capacity: | 5,000,000pcs Per month. |

11.Payment Term: | (1) L/C, T/T, D/P |

Applications of PPR Pipe (white, gray):

1) Cold and hot water supply systems for civil and industrial constructions, e.g. in residential buildings, hospitals, hotels, school and office buildings, ship building

2) Drinking water systems and food industry pipe works

3) Central air conditioning system

4) Irrigating system for gardens and green houses

5) Public and sport facilities such as swimming pools and stadiums

6) For rainwater utilization systems

Packaging Details:

1. Large carton: 515 x 400x 220 Cubage: 0.04532 M3

Small carton: 390x255x250 Cubage: 0.0248 M3

2. PE poly bag+ carton Delivery Detail: 15 days/ 20" containers; 25 days/ 40HQ

FAQ

Q1: How Can I Get a Sample?

A1: You can get samples by communicate with our export sales.

Q2: How Long Is Delivery?

A2: Delivery time will be30-45days according to order quantity.

Q3: What Is The MOQ?

A3: MOQ depends on different items.

Q4: What Is Our Normal Payments Terms?

A4: Our normal payment terms now is: T/T, L/C or western union, MoneyGram.

- Q:What quota should plastic tube be fitted?

- In the pipeline installation, the plastic flange sleeve quota can be carried out according to the following conditions: installation engineering, plastic pipe installation, plastic flange installation, included in the flange valve

- Q:Are plastic pipe fittings resistant to static electricity?

- No, plastic pipe fittings are generally not resistant to static electricity.

- Q:How to connect the wire mesh, steel tape and plastic composite pipe?

- Welding connection fittings using internal heating pipe fittings with inner plastic outer plastic melt, the pipes and fittings reliably connected together, but in order to ensure the whole pipeline system and under the same pressure, electric melting pipe is usually adopted in the production of Steel Lining Reinforced way.

- Q:Are plastic pipe fittings prone to leaks?

- Plastic pipe fittings are generally less prone to leaks compared to other materials such as metal or rubber fittings. However, just like any other fittings, the risk of leaks can still exist if they are not installed properly or used beyond their recommended limits. Regular inspection and maintenance are crucial to ensure a leak-free plumbing system.

- Q:Are plastic pipe fittings resistant to mechanical stress?

- Yes, plastic pipe fittings are generally resistant to mechanical stress. They are designed to withstand pressure, impacts, and other external forces commonly encountered in plumbing systems. However, the specific level of resistance may vary depending on the type and quality of the plastic used in the fittings.

- Q:Can plastic pipe fittings be used in fish tank systems?

- Yes, plastic pipe fittings can be used in fish tank systems. They are commonly used for plumbing and filtration purposes due to their durability, flexibility, and resistance to water damage. However, it is essential to ensure that the type of plastic used is non-toxic and safe for aquatic life. Regular monitoring and maintenance should also be carried out to prevent any potential leaks or damage that could harm the fish.

- Q:Can plastic pipe fittings be used in mining applications?

- Yes, plastic pipe fittings can be used in mining applications. They are often preferred due to their corrosion resistance, lightweight nature, and ease of installation. Plastic fittings can effectively handle the demands of mining operations while also offering cost and maintenance benefits.

- Q:Can plastic pipe fittings be used for fuel transfer systems?

- No, plastic pipe fittings are generally not recommended for use in fuel transfer systems due to their potential to degrade or become brittle when exposed to certain fuels, leading to leaks or failures. It is advisable to use fittings specifically designed and approved for fuel transfer applications, such as those made from materials like brass or steel.

- Q:Do plastic pipe fittings require any special threading or grooving?

- No, plastic pipe fittings do not require special threading or grooving. They are typically designed to be easily joined together using compression fittings, solvent welding, or push-fit connections.

- Q:Can plastic pipe fittings be used for pneumatic conveying systems?

- Yes, plastic pipe fittings can be used for pneumatic conveying systems. Plastic pipe fittings, such as PVC or HDPE, are commonly used in pneumatic conveying systems due to their lightweight, corrosion resistance, and cost-effectiveness. They provide a reliable and durable solution for conveying materials in pneumatic systems. However, it is important to select fittings that are specifically designed for pneumatic conveying applications and ensure they can handle the required pressure and flow rates.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR pipe and fittings used in Industrial fields 2017 new

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords