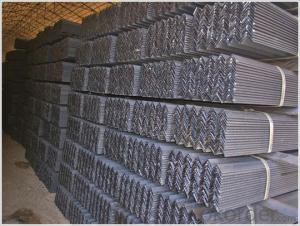

Hot Rolled Steel Angle Bar with High Quality 100*100mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 100*75*7 | 9.32 | 100*75*10 | 13.0 |

| 100*75*8 | 10.6 | 100*75*12 | 15.4 |

| 100*75*9 | 11.8 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q:How do you determine the required thickness of a steel angle for a specific load?

- Several factors need to be taken into account in order to determine the necessary thickness of a steel angle for a specific load. Firstly, it is essential to establish the load that will be exerted on the steel angle. This can be achieved by examining the structural design or intended purpose of the steel angle. The load may be either static, such as the weight of a structure, or dynamic, like the force from moving objects or wind. Once the load is known, the subsequent step involves calculating the bending moment and shear force that the steel angle will endure. The bending moment measures the degree of flexing or bending of the steel angle under the applied load, while the shear force measures the internal forces acting parallel to the cross-sectional area. Typically, engineering principles and formulas such as the moment of inertia and maximum stress formula are employed to calculate the bending moment and shear force. These calculations consider the dimensions of the steel angle, the applied load, and the properties of the steel material. Once the bending moment and shear force are determined, the required thickness of the steel angle can be calculated. This calculation necessitates the selection of an appropriate safety factor, which accounts for uncertainties and potential variations in the applied load or the strength of the steel material. The safety factor is typically determined by industry standards or codes. Using the maximum stress formula, which relates the bending moment, shear force, and dimensions of the steel angle to the stress experienced by the material, the required thickness can be calculated. By rearranging the formula, the necessary thickness can be solved for, ensuring that the steel angle is sufficiently strong to withstand the applied load without failure or deformation. To summarize, determining the necessary thickness of a steel angle for a specific load involves analyzing the load, calculating the bending moment and shear force, selecting a safety factor, and utilizing the maximum stress formula to solve for the required thickness. It is crucial to consult engineering principles, codes, and standards to ensure that the steel angle is appropriately sized to withstand the applied load.

- Q:Are steel angles resistant to impact or vibration?

- Steel angles are known for their high strength and durability, making them generally resistant to impact and vibration. However, the specific resistance to these forces would depend on various factors such as the thickness and quality of the steel, as well as the magnitude and frequency of the impact or vibration.

- Q:Can steel angles support heavy machinery or equipment?

- Yes, steel angles can support heavy machinery or equipment. Steel angles are commonly used in construction and engineering due to their strength and durability. They are typically made from hot-rolled steel and can withstand heavy loads and forces. Steel angles provide structural support and stability, making them suitable for supporting heavy machinery or equipment. They are often used as frames or brackets to hold and secure heavy objects. Additionally, steel angles can be welded or bolted together to create a strong and stable base for heavy machinery. Overall, steel angles are a reliable choice for supporting heavy machinery or equipment due to their high load-bearing capacity and structural integrity.

- Q:Are steel angles suitable for balcony construction?

- Indeed, balcony construction can make use of steel angles as they possess the necessary qualities of strength and durability. In construction, steel angles find frequent application due to their exceptional support and stability, rendering them an ideal choice for balcony construction. The capacity of steel angles to withstand heavy loads and resist weathering and corrosion further solidifies their reliability for outdoor structures like balconies. Moreover, the customizable and fabricable nature of steel angles enables them to be tailored to specific design requirements, offering flexibility in balcony construction. Ultimately, the strength, durability, and versatility of steel angles contribute to their popularity and suitability for balcony construction.

- Q:How do steel angles perform under dynamic loads?

- Steel angles generally perform well under dynamic loads due to their inherent strength and durability. The structural shape of steel angles, characterized by their L-shaped cross-section, provides excellent resistance to bending and torsional forces. This design allows them to efficiently distribute dynamic loads and resist deformation, making them suitable for various applications in construction, engineering, and manufacturing industries. However, the specific performance of steel angles under dynamic loads can vary depending on factors such as the grade and quality of the steel, the magnitude and frequency of the dynamic load, and the overall design and reinforcement of the structure.

- Q:Can steel angles be used in staircases?

- Steel angles are indeed suitable for use in staircases. Due to their strength and versatility, they are commonly employed as structural components in construction. In staircases, steel angles serve to offer support and stability to both the steps and handrails. They are frequently utilized as stringers, inclined structural members that uphold the treads and risers of the staircase. Moreover, steel angles can be utilized to reinforce the connections between the treads and risers, thereby ensuring the staircase's structural integrity. Furthermore, steel angles can function as handrails or balusters, providing a secure and long-lasting railing system. All in all, steel angles present a dependable and cost-effective solution for constructing staircases that can withstand heavy loads and meet the necessary safety standards.

- Q:Can steel angles be used in mezzanine or raised platform constructions?

- Mezzanine or raised platform constructions can incorporate steel angles, which are flexible structural elements capable of providing support and stability in construction projects. Due to their strength and ability to bear heavy loads, steel angles are frequently utilized as framing members in mezzanine or raised platform structures. Their connection to other steel components like beams and columns is effortless, enabling the creation of a robust framework for the mezzanine or raised platform. Moreover, steel angles can serve as bracing and reinforcement elements, thereby enhancing the structure's overall stability and safety. In summary, steel angles are a commonly chosen option for mezzanine or raised platform constructions due to their durability, versatility, and cost-effectiveness.

- Q:How do you calculate the deflection of a steel angle?

- To calculate the deflection of a steel angle, you need to use the principles of structural engineering and specifically apply the formulas for calculating deflection in beams. These formulas typically take into account the material properties of the steel angle, such as its Young's modulus and moment of inertia, as well as the applied load and span length. By plugging these values into the appropriate equation, you can determine the deflection of the steel angle under the given conditions.

- Q:Can steel angles be used for balcony railings?

- Yes, steel angles can be used for balcony railings. Steel angles are commonly used in construction for their strength and durability. They provide structural support and can be easily customized to fit the specific dimensions and design requirements of a balcony railing. Additionally, steel angles can be painted or coated to match the desired aesthetic of the balcony. However, it is important to ensure that the steel angles used meet the necessary safety standards and building codes to ensure the stability and security of the balcony railing.

- Q:Are steel angles suitable for rooftop installations?

- Yes, steel angles are suitable for rooftop installations. They are commonly used in construction for their strength and durability. Steel angles provide structural support and can be easily attached to rooftops to secure various installations such as solar panels, antennas, or HVAC equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 100*100mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches