Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

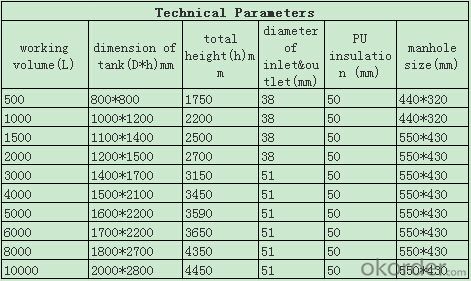

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

- Q:HIya--I have a vent pipe that goes from the boiler to the chimney---it has a few holes in it that kind of look like someone punched them into the pipe years ago--is there a reason someone may have done that? there is hot air leaving this pipe up the chimney,,,were they trying to send some of this into the basement? should I plug them? thanks for any info!

- Plug them now if you can and you must have the boiler on, replace the pipe as soon as possible. Like get new pipe today if you can do this yourself, or call a service person today. Those gasses are the combustion gasses, and could contain various amounts of carbon monoxide which is poisonous.

- Q:How many times does the boiler check inside?

- In addition to the normal periodic inspection, the boiler should have the following test, the following test should be carried out.

- Q:Its a combi bolier and is serviced but Engineers have not found reason

- u can isolate the radiators from the boiler using the isolation valves fitted on the bottom of the boiler. if the pressure stays the same u are losing pressure in the radiators,if the pressure still drops u r losing pressure in the boiler.before u isolate the radiators make sure the boiler is set for hot water only.u could also change your engineer

- Q:there's alot of detail in the new molds i have which require different colors, does the dbl boiler method keep the candy melty longer? and wut should the consistency b when painting in 'features of the face' ?

- For a quick method it's the microwave, but for more control it's the double-boiler. And, yes, the double-boiler method is a real help in keeping the candy melted longer. Consistency? The candy melts just have to be warm enough to work with, so you may have to adjust it as you work. You must refrigerate, or at least let set, between color changes, or the colors will run together. Here are some tips instructions on painting. Painting Details: Adding color details to candies makes them more realistic much more fun! For large areas of color, it's best to paint the melted candy right in the mold before the whole candy is molded using a decorator brush. Or, for very small details like vines, mouths messages, melted candy should be piped onto molded candies using a parchment bag with a small hole cut in the tip. 1. Melt desired Candy Melts colors in the microwave, in a double boiler, or by using a Candy Melting Plate. With decorator brush, paint areas of candy molds with melted candy. 2. Refrigerate mold a few seconds until candy is firm, repeating for each additional color. 3. Fill mold to top with melted candy, tap, refrigerate until firm unmold. For best results, always fill in one section of the mold at a time let set before adding additional colors. Piping Details: Piping is the way you can add designs or details by controlled squeezing of melted candy, icing, etc., from a decorating bag. Just squeeze from the bag onto your molded candy. It's easy to add hair, facial features, clothes or other designs to candy. When using parchment bags: Follow Parchment Triangles package instructions to prepare one bag for each color. Melt the candy separately before placing in parchment bags, then spoon it into bags. Using scissors, cut a small opening in tip and squeeze candy on molded candy. You can also reheat candy if it hardens in the bag by placing the bag back in the microwave or on a warming tray.

- Q:what is a boiler room brawl?BQ: how many points are required to be Level 3 on Y! Answers?

- a brawl in a bioler room bq 1000 then 2500 to level 4

- Q:In boiler,how drum level can be measured by differential pressure transmitter.How can we give minimum and maximum value.Explain with example

- A differential-pressure transmitter adapted to produce a signal proportional to a process variable such as flow rate in a line conducting fluid or the level of liquid in a tank, the process fluid being at a temperature markedly at variance with ambient temperature. The transmitter is constituted by high and low pressure sensors which are coupled to the force beam of a force balance transducer so that the beam is responsive to the difference between sensed high and low pressures derived from the process variable, the transducer being exposed to ambient temperature. Each sensor is constituted by a housing having a well therein covered by a sensing diaphragm and an insert seated in the well, the face of the insert being spaced from the diaphragm to define a fill chamber containing hydraulic fluid, the sensor diaphragm being exposed to the process liquid, whereby heat transfer takes place between the liquid and the hydraulic fluid. The insert is formed of a metal having a low coefficient of expansion relative to the material of the housing whereby variations in temperature produce changes in the dimensions of the housing relative to that of the insert and give rise to changes in the volume of the fill chamber to an extent compen

- Q:I just noticed our boiler (upright, gas, cylindrical type) is leaking HOT water. Our boiler is outside the house and currently in the sun. It is housed, however. Anyways, it's leaking hot water---actually it's more running than leaking. EDIT: upon further inspection, it seems the water is coming from the top of the boiler and then going down the sides. The water is hot and has some steam to it...there's a puddle below...since then we've just shut the water off so it stops, but we need water so where do we go from here?-Is it dangerous? -What to we need to do? Note: ---that we've had a leak the last few weeks in the bathroom---and temps outside were in the 50/60's for a few days and now are at the upper 80's, but that shouldn't matter, right? HELP--I'm pretty scared of boilers...it's not going to explode, right?

- Boilers need to have relief valves. You can probably look up how to test the relief valve to ensure that it won't explode It sounds like the tank could have been damaged by something... You need to look it over carefully. Might be that the pipes weren't properly secured and supported allowing for things to move them around putting stress on the joint at the tank. Could be a broken pipe, a cracked tank, a damaged connector... you just need to look at it. If it's a cracked tank, you need a new one. If it's damaged pipes you can repair them. Be sure to try and determine what caused the damage to try and prevent it from happening again. Don't use water pipes for clothes hangers. Shield the tank fully from things like flying rocks or tree branches...

- Q:In pr, what is a boiler plate?

- boilerplate refers to common language that is used over and over in a particular field. Not jargon, but phrases or even whole paragraphs that are always in a lease, for instance, or a contract.

- Q:limits to be set on low pressures steam boilers?

- Low pressure steam boilers are those rated not more than15psig. These low pressure steam boilers are commonly used in hotels, restaurants and hospitals. These boilers should have pressure switches which trips the power supply at 15 psi. Also these boilers should have at least two mechanical relief valves which will release steam automatically once the set pressure is reached. For safety however,one should conduct a hydrostatic pressure test during a shutdown,of at least 200 % of the boiler operating rating and check if the shell does not give way.

- Q:I noticed at the place we live a plumber/electrician came out and installed something thats called a boiler pipe?? what is it? and what does it do? just wondering we weren't told anything since its a rental. and now our water pressure seems to be low?? thanks!

- difficult step. lookup in google and yahoo. that may help!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Homemade Beer Fermentation with CE Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords