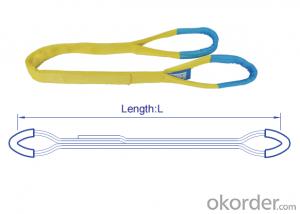

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

Certification: GS, CE, ISO

Customized support: OEM, ODM

Application: Lifting Goods

Safety factor: 5:1 6:1 7:1 8:1

Length: Customized Length

Width: Customized Width

Standard: CE/GS/ISO9001

Packing: Customers Requiement

MOQ: 1 Piece

Chracteristics:

Soft, light, no harm to the cargo, safety, long life and so on.

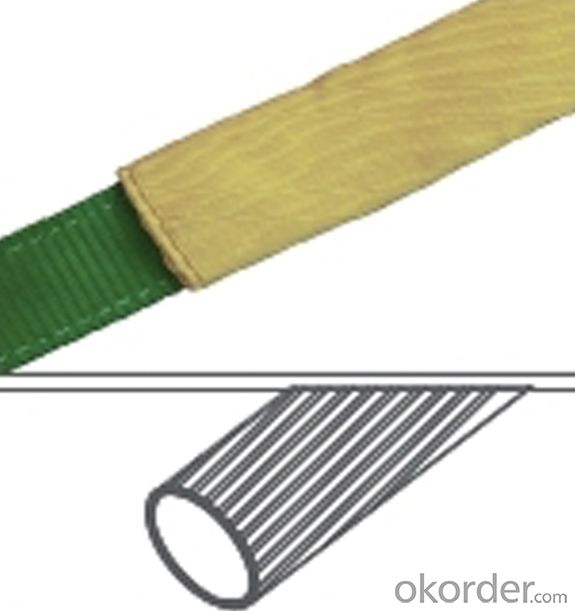

Light and soft, can be used in small narrow space.In PU processing, anti-abrasion is enhanced,Non-conductive, no danger of electric stroke.

Product usage :

Textile slings are widely used for lifting, pulling, bundling, fixed and other operations in machining, port handling, marine engineering, ship, electric power, transportation, erospace and other fields.

Company Profile:

We are able to manufacture special slings such as high-strength type, flame retardant type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant type, fluorescent type, optical inspection type and oil and water resistant type sling.

Shipping:

1.Selling Units:Single item

2.Single package size: 30X4X5 cm

3.Single gross weight:1.210 kg

4.Package Type:Shrink-packaging + Carton Box + Pallet

Certificate:

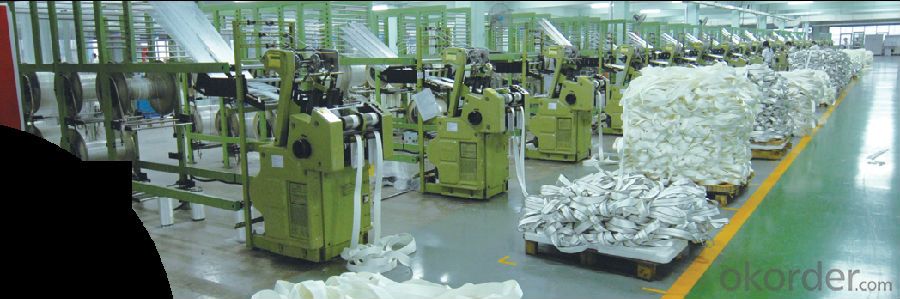

Textile sling factory is the largest base for lifting belts in the world with the production capacity "over 20000t.We have thousands of manufacturing equipments, including Muller weaving machines "from Switzerland,dyeing machines from Germany and automatic sewing machines form Japan,etc. The main products are: webbing sling, round sling, ratchet strap, assembly sling, mooring rope "and traction rope, according to different using environments, different materials would be used, "such as polyester, polypropylene, nylon, Kevlar and HMPE (high molecular weight polyethylene "material).

We are able to manufacture special slings such as high-strength type, flame retardant "type, anti - slip type, wear - resistant type, acid and alkali resistant type, high temperature resistant "type, fluorescent type, optical inspection type and oil and water resistant type sling. With characteristics like soft, light, no harm to the cargo, safety, long life and so on.

Product usage : Textile slings are widely used for lifting, pulling, bundling, fixed and other "operations in machining, port handling, marine engineering, ship, electric power, transportation, "aerospace and other fields. Achievements in scientific research:In 1997, we drafted out the industrial standard for textile "slings together with Beijing Hoisting Machinery Institute: JB/T8521-1997, which makes historic "progress for the Chinese textile sling industry. "In 2007, we revised JB/T8521.1-2007"Textile Sling – Safety - Part 1: Common use webbing "sling" and JB/T 8521.2-2007"Textile Sling - Safety - Part 2: Common use round sling". In 2009, we edited GB/T 23914.2-2009"Road vehicle mounted fixtures – Safety – part 2: "Synthetic ratchet strap assemblies", participated in writing TB/T 3123.11-2009"Rescue devices for "railway accidents - part 11: high-performance textile sling". In 2014, we participated in writing GB/T 30667-2014"Polyester and polyolefin dual Fiber rope "and GB/T 30668-2014"8 strands, 12 strands and multiflament braided Ultra high molecular weight "polyethylene fiber rope".

- Q:What is the name of the wire above the train?

- The catenary provides 25 thousand volt power frequency alternating current for the locomotive, according to the locomotive model difference, adopts the direct step-down, the frequency conversion power supply or the AC and DC conversion power supply, this is mainly for the speed regulation convenience.

- Q:What are the dangerous sections of the crane hook?

- ) C -C section of the section is the thinnest part of the hook column in a sling tension, have pulled off the trend. Here the maximum tensile stress, it is also dangerous section.

- Q:How do you tie the wire rope?

- Manganese phosphating belongs to wear, corrosion, phosphating, automobile transmission, steel gear is through the manganese phosphating treatment, can ensure that the car gear for more than ten years without damage. Phosphating coating of steel wire rope China patent technology production, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just add the last bonderizing process, steel wire for rope wear resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope. The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of domestic smooth steel wire rope, wire rope surface is 2-3 times of imports, (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility, is currently the most advanced technology in the world of steel wire rope field. Manganese phosphating is bonderizing, can solve the problem of wire rope wear during use, smooth wire rope being eliminated, because the phosphating coating steel wire rope in short supply, the more sought after, need to ask a few companies.

- Q:How to choose the right sling?

- Commonly used slings and slings are lifting belts, lifting chains and wire ropes. Slings and slings must be matched with lifting equipment, such as 5 tons or 10 tons. Cranes shall be marked with maximum lifting weight. Lifting belt will not damage the hoisting object but poor wear resistance, easy maintenance but large weight lifting chain, rope buckle range but the broken wire after easily scratch objects and operators, each have advantages and disadvantages, to meet their own needs is the best lifting.Phosphating coating of steel wire rope production technology patent, give priority to the use of manganese or zinc manganese phosphating, and smooth steel wire rope production process comparison, just increase the steel wire wear phosphating process, phosphating of steel wire surface after the abrasion resistance and corrosion resistance is greatly improved, the use of direct phosphating steel wire twisting steel wire rope (steel wire after phosphating not drawing). The fatigue test data show that the fatigue life of the phosphating coating of steel wire rope is about 3-4 times the same structure of plain steel wire rope, wire rope is 2-3 times of imports (laboratory comparable conditions) with the research on the wear resistance of phosphating, and greatly enhance the possibility of. Manganese phosphating is wear resistant phosphating, which can completely solve the wear problem in the use of wire rope.

- Q:What is the safety factor of the wire rope as a motor lifting equipment, slings and slings?

- 4. coated steel wire rope, the carbon steel wire rope based on the rope or rope coated with polyethylene or polypropylene5. smooth wire rope, in 1834 the British began production in China in 1939 started production in Tianjin No.1 steel wire rope factory, with the phosphating coating steel wire rope into the market size gradually increased, will be fully replace phosphating coating steel wire rope.

- Q:What torture refers to the lever and the sling

- China used suspension has a special method commonly used, is the only victims of hanging to toe the height, so that the victims are difficult to completely rely on the wrist or thumb under the weight of the whole body, and can not completely rely on the toes to support the body, is very painful, this is the unique China torture method.There is a special way of suspension is relatively rare, is the so-called "monkey holding pile", will be the victims before the hands (also can only bind the thumb to hold the two) was forced to bend the knee, the knee bend into a stick with a rope, lifting the stick ends (also stick to a certain height of the frame other instruments). When the victims of the buttocks, genitals and soles of the feet completely exposed, for the use of other means torturer. In this gesture, the wrist (thumb), knee joint, waist and neck will be squeezed, twisted and pulled by the weight of each part of the body. It is very painful, and Yang Kaihui has been subjected to the punishment.

- Q:What's the sling for a movie?

- WIA, is used to protect the athlete's device is generally with a strong rope tied to the athlete's protection belt.

- Q:What are the precautions for rigging in hoisting works?

- The load weight shall not exceed the limit load of sling, sling should be used before the use of visual inspection, and according to the spreader lifting load check the working load limit, meet the requirements before use.

- Q:Does the pressing rope have any influence on the tension value of the wire rope?

- According to the current market price of the phosphating coating steel wire rope, phosphating coating steel wire rope daily use cost is just plain steel wire rope about thirty percent of phosphating coating steel wire rope is a substitute for plain steel wire rope upgrade, for reference only.

- Q:Why are the suspension bridges a main cable, even a n multi sling, not a bridge directly from the tower?

- Finally, the gravity of the main beam becomes the two vertical force of the tower, so that the force passes to the pier under the tower.There are more cables, and the same reason. There are a lot of bars, that's to distract the main girder from the cables.As a kind of cable of cable-stayed bridge, more than beam bridge spanning capacity is the main bridge of long span bridges. The cable stayed bridge is composed of many cables which are directly connected to the tower. The cable-stayed bridge is composed of pylon, main beam and stay cable. The types of pylon are A, inverted Y, H and single column. The materials are steel and concrete. There are single cable plane, parallel double cable plane and inclined cable plane in the stay cable. The first modern cable-stayed bridge was built in Sweden in 1955 and has a span of 182 meters. At present, the largest span cable-stayed bridge built in the world is the Normandy bridge in France, with a main span of 856 meters. The Shanghai Yangpu bridge, built in 1993, is the largest cable-stayed bridge in China, with a main span of 602 meters

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireproof Type Textile Sling Webbing Sling ODM&OEM Customization

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches