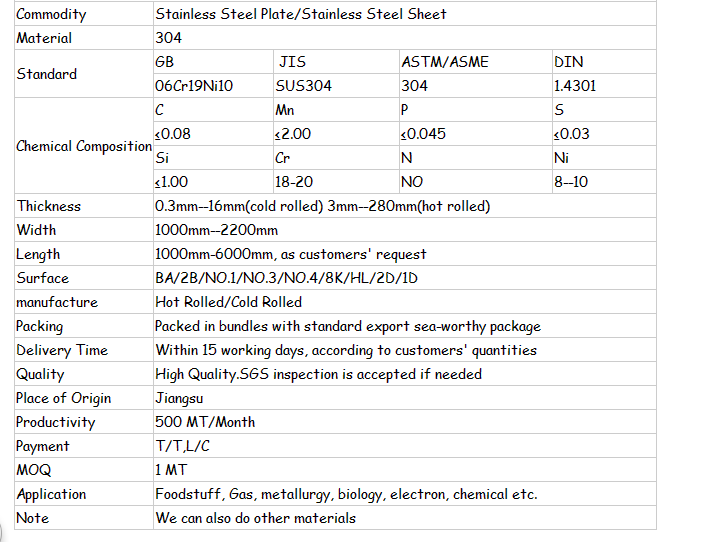

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Are stainless steel pipes suitable for extreme temperatures?

- Yes, stainless steel pipes are suitable for extreme temperatures. Stainless steel is known for its high temperature resistance and ability to withstand both low and high temperatures without losing its structural integrity or mechanical properties. It can handle extreme heat and cold, making it a reliable choice for various industrial applications, including those involving extreme temperature environments.

- Q:Are stainless steel pipes suitable for wastewater treatment facilities?

- Stainless steel pipes are a great fit for wastewater treatment facilities due to their exceptional corrosion resistance. This quality makes them perfect for managing highly corrosive wastewater. Their ability to resist chemicals and acids prevents deterioration, minimizing the chances of leaks and contamination. Moreover, stainless steel pipes are hygienic and effortless to clean, which is vital in maintaining cleanliness at wastewater treatment facilities. Furthermore, their high strength-to-weight ratio enables easy installation and reduces the necessity for extra support structures. Hence, stainless steel pipes are a dependable and long-lasting option for wastewater treatment facilities.

- Q:Are stainless steel pipes suitable for power generation plants?

- Yes, stainless steel pipes are suitable for power generation plants. Stainless steel is known for its excellent corrosion resistance, which makes it ideal for use in power generation plants that involve high temperatures, pressure, and corrosive environments. Power generation plants often use various types of fluids, such as steam, water, and chemicals, which can cause corrosion and degradation of the piping system. Stainless steel pipes can withstand these harsh conditions and provide long-lasting performance. Furthermore, stainless steel pipes have high strength and durability, which is crucial for power generation plants that operate at high pressures. They can handle the stress and strain of the system without the risk of failure or leakage. In addition, stainless steel is also resistant to scaling and fouling, which is important for maintaining the efficiency of the power plant. The smooth internal surface of stainless steel pipes helps to minimize friction and pressure losses, ensuring efficient flow of fluids. Moreover, stainless steel pipes are easy to maintain and clean. They do not require frequent inspections or repairs, reducing downtime and maintenance costs for power generation plants. Overall, the superior corrosion resistance, strength, durability, and efficiency of stainless steel pipes make them highly suitable for power generation plants. They offer a reliable and long-lasting solution for fluid conveyance in such demanding environments.

- Q:What is the difference between seamless and LSAW stainless steel pipes?

- The main difference between seamless and LSAW (Longitudinal Submerged Arc Welded) stainless steel pipes lies in their manufacturing process. Seamless stainless steel pipes are made by piercing a solid cylindrical billet and then rolling it into a pipe shape without any welding involved. On the other hand, LSAW stainless steel pipes are created by using a submerged arc welding process along the longitudinal seam of a steel plate. This welding process provides added strength and durability to the pipe. Both types of pipes have their own advantages and are used in different applications based on their specific characteristics.

- Q:How do stainless steel pipes compare to PEX pipes?

- Stainless steel pipes and PEX pipes have different characteristics and applications. Stainless steel pipes are known for their strength, durability, and resistance to corrosion, making them ideal for high-pressure and high-temperature applications. They are commonly used in industrial settings and for water supply systems. On the other hand, PEX pipes are flexible, lightweight, and easy to install, making them suitable for residential plumbing systems. PEX pipes have good resistance to freezing and are less prone to leaks compared to other materials. Ultimately, the choice between stainless steel and PEX pipes depends on the specific needs and requirements of the project.

- Q:Can stainless steel pipes be used in the automotive industry?

- Indeed, stainless steel pipes find utility in the automotive industry. Renowned for their high durability and resistance to corrosion, stainless steel proves to be an optimal material for a multitude of automotive applications. In exhaust systems, stainless steel pipes are frequently employed due to their ability to endure elevated temperatures and combat the corrosive impact of gases and condensation. Furthermore, they are indispensable in fuel delivery systems, brake lines, and hydraulic systems, where their robustness and immunity to corrosion are of paramount importance. In summary, stainless steel pipes exhibit exceptional performance and longevity in the arduous circumstances of the automotive sector.

- Q:Are stainless steel pipes suitable for food and beverage processing?

- Yes, stainless steel pipes are highly suitable for food and beverage processing. Stainless steel is a popular material choice in the food and beverage industry due to its unique properties and benefits. Firstly, stainless steel is known for its corrosion resistance, which is essential in food and beverage processing where contact with various acids, chemicals, and moisture is common. This property ensures that the pipes remain hygienic and free from rust or contamination, guaranteeing the safety and quality of the processed food or beverage. Furthermore, stainless steel pipes have a smooth surface finish, making it difficult for bacteria, dirt, or other contaminants to stick to the walls of the pipe. This makes cleaning and sanitization easier and more effective, reducing the risk of cross-contamination. Another advantage of stainless steel pipes is their high heat resistance. They can withstand high temperatures without warping or deforming, making them suitable for various food processing applications such as pasteurization or sterilization. Additionally, stainless steel is a non-reactive material, meaning it does not react with the food or beverage being processed. This ensures that the taste, odor, and quality of the final product are not compromised. In conclusion, stainless steel pipes are an excellent choice for food and beverage processing due to their corrosion resistance, easy cleanability, high heat resistance, and non-reactive properties. These qualities make them a safe and reliable option for maintaining the hygiene and quality standards required in the industry.

- Q:Can stainless steel pipes be bent or shaped easily?

- Yes, stainless steel pipes can be bent or shaped easily with the appropriate tools and techniques.

- Q:Are stainless steel pipes suitable for underground applications?

- Yes, stainless steel pipes are suitable for underground applications. Stainless steel is known for its high resistance to corrosion, making it an excellent choice for underground installations where pipes are exposed to moisture, soil, and other corrosive elements. It can withstand harsh environments and maintain its structural integrity over time. Stainless steel pipes also have high strength and durability, ensuring they can handle the pressure and stress of being buried underground. Additionally, stainless steel is non-reactive, so it does not contaminate the water or fluid flowing through the pipes. Overall, stainless steel pipes are a reliable and long-lasting option for underground applications.

- Q:Can stainless steel pipes be insulated with mineral wool?

- Yes, stainless steel pipes can indeed be insulated with mineral wool. Mineral wool is a common and effective insulation material used in various industries, including plumbing and construction. It is capable of withstanding high temperatures and offers excellent thermal and acoustic insulation properties. Additionally, mineral wool is non-combustible and resistant to moisture, making it suitable for insulating stainless steel pipes that carry hot or cold fluids. The insulation can help prevent heat loss, reduce energy consumption, and protect against condensation and pipe sweating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords