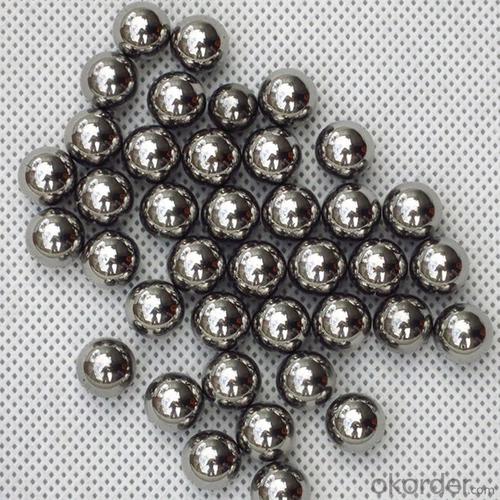

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Cold Drawn

Shape:

Round

Surface Treatment:

Dry

Steel Grade:

420

Thickness:

0.045-2.8mm

Length:

0.045-2.8mm

Net Weight:

20kg/bag

Packaging:

Standard Export Packing

Product Description

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

Products Picture

| Product | AISI420 G100 6mm Shot Magnetic Stainless Steel Balls |

| Material | stainless steel |

| Pericision | G100 |

| Hardness | HRC25-39 |

| Surface | zero defect , bright |

| Checking | 100% sorted |

| Sales mode | wholesale or retail |

| Sample | by free |

| Safe | ROHS |

| Package | four small boxes within a carton of20kg |

Expect the stainless steel ball , we have other steel balls . carbon steel ball , chrome steel ball .

In our company . The chrome steel ball have used in bearing , screw , grinding . The carbon steel ball have used in bicycle bearing ,slide. The stainless steel ball have used nail polish , grinding chocolate.

WHAT UNIQURE FEATURE DO I HAVE?

Products Picture

our company have the strict process :Raw material--Wire drawing--Cold heading--Flashing--Heat treatment--Grinding--Lapping1--Lapping2--Lapping3--Washing--Checking--Packing

High efficiency / High efficiency inspection

Our production capacity is 160 tons per month. we have the high quality testing instruments

for example : roundness measuring equipment , photometric sorter, metallographic structure detector, vibroscope,salt spray tester.

Green product

Our company product are all passed the ISO and SGS certification . They are all safe.

- Q:How does steel pipe threading work?

- Steel pipe threading is a process where a machine is used to cut threads into the ends of steel pipes. The machine grips the pipe securely and rotates it while simultaneously cutting or forming the threads using a die or cutting tool. This creates a threaded connection that can be used to join pipes together or attach fittings, ensuring a tight and secure seal. Threading is commonly used in plumbing, construction, and industrial applications.

- Q:How is steel used in the production of consumer goods?

- Steel is used in the production of consumer goods in various ways, such as in the manufacturing of appliances, automobiles, furniture, tools, and packaging materials. It is valued for its strength, durability, and versatility, making it an essential material for constructing and designing a wide range of products that are used by consumers on a daily basis.

- Q:What are the different types of steel stair treads and nosings?

- There are several types of steel stair treads and nosings available, including diamond plate treads, serrated treads, perforated treads, and abrasive nosings. Each type offers specific benefits such as slip resistance, durability, and ease of maintenance, catering to various safety and aesthetic requirements in different environments.

- Q:How is steel used in the production of mining equipment?

- Steel is commonly used in the production of mining equipment due to its strength, durability, and resistance to harsh conditions. It is used to manufacture various components such as buckets, shovels, drill bits, and machinery frames, ensuring they can withstand the rigorous demands of the mining industry.

- Q:How is steel wire used in the production of springs for automobiles?

- Steel wire is commonly used in the production of springs for automobiles due to its high strength and durability. It is typically formed into coil shapes to create suspension springs, ensuring a smooth and stable ride. Additionally, steel wire is utilized in the manufacturing of valve springs, clutch springs, and seat springs, providing the necessary flexibility and resilience required for these automotive components.

- Q:How is steel used in the manufacturing of textile materials?

- Steel is used in the manufacturing of textile materials through various applications such as the construction of textile machinery, production of textile accessories like pins, needles, and hooks, as well as in the manufacturing of textile machinery parts, tools, and equipment. Additionally, steel is also utilized for the construction of textile factories and warehouses, providing the necessary structural support and strength for these facilities.

- Q:What are the different types of steel reinforcements used in construction?

- There are several different types of steel reinforcements used in construction, including rebar (reinforcing bar), welded wire mesh, and post-tensioning systems. Rebar is the most common type and consists of steel bars or rods that are placed in concrete structures to increase their strength and resistance to tension. Welded wire mesh is made up of welded steel wires arranged in a grid pattern and is primarily used for reinforcing concrete slabs and walls. Post-tensioning systems involve pre-stressing steel cables or tendons within concrete structures to enhance their load-bearing capacity. These different types of steel reinforcements play crucial roles in ensuring the durability and structural integrity of construction projects.

- Q:What are the different types of steel beams used in building structures?

- There are several types of steel beams commonly used in building structures, including I-beams, H-beams, and wide flange beams. I-beams, also known as W-beams, have a cross-section shaped like the letter "I" and are commonly used in residential and commercial construction. H-beams, also known as H-shaped beams, have a cross-section shaped like the letter "H" and are often used in bridge construction. Wide flange beams, also known as W-flange beams, have a wider flange than I-beams and are commonly used in industrial and commercial construction.

- Q:What is the role of steel in earthquake-resistant building design?

- Steel plays a crucial role in earthquake-resistant building design as it provides strength, ductility, and flexibility to withstand seismic forces. It is used in the construction of structural frames, beams, columns, and reinforcement bars, helping buildings absorb and distribute the energy generated during an earthquake. Additionally, steel's high strength-to-weight ratio allows for lighter and more efficient designs, making it an essential material for ensuring the safety and resilience of structures in seismic zones.

- Q:What are the different types of steel forgings and their applications in the defense industry?

- There are three main types of steel forgings used in the defense industry: carbon steel forgings, alloy steel forgings, and stainless steel forgings. Carbon steel forgings are known for their strength and durability, making them suitable for various applications in defense, such as weapon components, tank tracks, and armor plating. Alloy steel forgings are made by adding various alloying elements to carbon steel, enhancing their strength, toughness, and resistance to wear and corrosion. These forgings are commonly used in critical defense components like aircraft landing gear, missile parts, and submarine propellers. Stainless steel forgings, on the other hand, are highly resistant to corrosion and have excellent mechanical properties. These forgings find applications in the defense industry, particularly in naval vessels, submarines, and aircraft carriers, where they are used for valves, pumps, shafts, and other critical components. Overall, steel forgings play a vital role in the defense industry by providing the required strength, durability, and performance needed for various defense applications, ensuring the safety and reliability of military equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AISI420 G100 6mm Shot Magnetic Stainless Steel Balls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords