Geogrid Tieback

Geogrid Tieback Related Searches

Geogrid Tbl Bonded Geogrid Laying Geogrid Geogrid Anchors Geogrid Alternative Geogrid Placement Geogrid Machine Geogrid Layer Bidirectional Geogrid Geogrid Parking Geogrid Rank Tracking Geogrid Maps Geogrid On Slope Geogrid Comparison Heet Geogrid Keystone Geogrid Woven Geogrid Geogrid Overlap Earthlock Geogrid Composite Geogrid Geogrid Gravel Geogrid Stabilization Geogrid Mat Geogrid Paving Geogrid Retaining Walls Geogrid Tensar Geogrid Viewer Retaining Wall Geogrid Geogrid Blocks Tenax GeogridGeogrid Tieback Supplier & Manufacturer from China

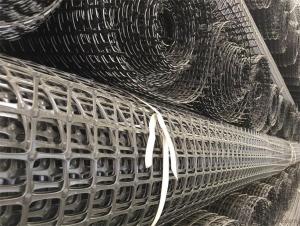

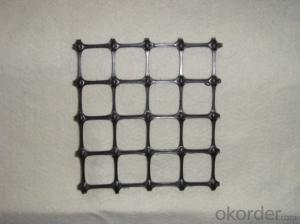

Geogrid Tieback is a specialized product that combines geogrids and soil nails to provide effective soil reinforcement and slope stabilization. This innovative system is designed to enhance the strength and stability of soil structures, making it an essential component in various civil engineering projects.The Geogrid Tieback system is widely used in applications such as retaining walls, slope stabilization, and excavation support. It is particularly effective in situations where traditional methods of soil reinforcement are not sufficient, providing a more robust and reliable solution. The system works by embedding soil nails into the ground and connecting them to a geogrid, which distributes the load and prevents soil movement.

Okorder.com is a leading wholesale supplier of Geogrid Tieback systems, offering a vast inventory of high-quality products to meet the needs of various projects. With a commitment to excellence, Okorder.com ensures that each Geogrid Tieback system is manufactured to the highest standards, providing customers with reliable and durable solutions for their soil reinforcement requirements.

Hot Products