Dupont Geogrid

Dupont Geogrid Related Searches

Geogrid Machine Home Depot Geogrid Unilock Geogrid Alliance Geogrid Honeycomb Geogrid Geostar Geogrid Geogrid Placement Geogrid Layer Geogrid Home Depot Geogrid Viewer Gmb Geogrid Composite Geogrid Extruded Geogrid Geogrid Tensar Bidirectional Geogrid Heet Geogrid Geogrid Membrane Miragrid Geogrid Geogrid Mat Huesker Geogrid Keystone Geogrid Landscaping Geogrid Universal Geogrid Grass Geogrid Terragrid Geogrid Erosion Control Geogrid Driveway Geogrid Naue Geogrid Structural Geogrid Vegetated GeogridDupont Geogrid Supplier & Manufacturer from China

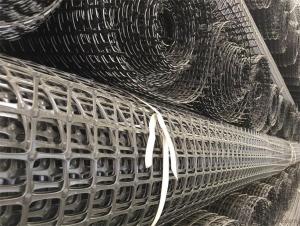

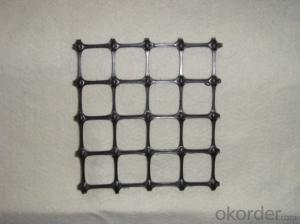

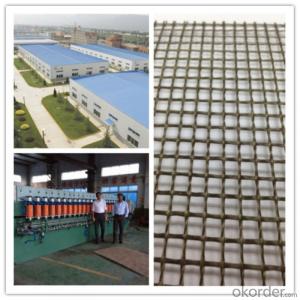

Dupont Geogrid is a range of high-performance geosynthetic products designed to enhance the stability and load-bearing capacity of various civil engineering projects. These products are widely recognized for their durability and effectiveness in applications such as soil reinforcement, slope stabilization, and foundation support. Dupont Geogrid's versatility makes it an ideal solution for a multitude of construction and infrastructure projects, where soil stabilization and reinforcement are critical for success.The application of Dupont Geogrid is extensive, encompassing a broad spectrum of usage scenarios in the civil engineering field. It is commonly used in road construction, railway beds, embankments, retaining walls, and other areas where soil reinforcement is necessary. By incorporating Dupont Geogrid into these projects, engineers can improve the overall performance and longevity of the structures, while also reducing the risk of soil erosion and subsidence. This product plays a crucial role in ensuring the stability and safety of various infrastructure projects, making it an invaluable asset in the construction industry.

Okorder.com is a leading wholesale supplier of Dupont Geogrid, boasting a large inventory that caters to the diverse needs of clients across different industries. As a reputable distributor, Okorder.com ensures that customers have access to high-quality Dupont Geogrid products at competitive prices. Their extensive inventory allows for quick turnaround times and efficient delivery, making them a reliable choice for businesses and contractors in need of geosynthetic solutions. By partnering with Okorder.com, customers can be confident in the quality and availability of Dupont Geogrid products for their projects.

Hot Products