ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZrO2 14.5% AR glass fiber roving

AR glassfiber spray roving is used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Specification of 14.5% Zro2 AR Glassfiber roving:

1.ZrO2 14.5% & 16.5%

2.2400Tex

3.Filament dia 15um

4.Moisture Content 0.09%

5.Breaking Strength 0.28N/tex

Technical Data of 14.5% Zro2 AR Glassfiber roving:

ZrO2 Content | % | JC935-2004 | 14.5±0.8 | 14.8 |

TiO2&ZrO2 Content | % | ≥19.2 | 19.3 | |

Filament dia | um | GB/T7690.5-2001 | 15±2 | 15 |

Strand tex | tex | GB/T7690.1-2001 | 2400±240 | 2460 |

Breaking Strength | N/tex | GB/T7690.3-2001 | ≥0.25 | 0.28 |

Moisture Content | % | GB/T9914.1-2001 | ≤0.2 | 0.09 |

Combustible Content | % | GB/T9914.2-2001 | 0.8-2.0 | 1.35 |

Stiffness | mm | GB/T7690.4-2001 | ≥120 | 150 |

Specific gravity | g/m3 | / | / | 2.7 |

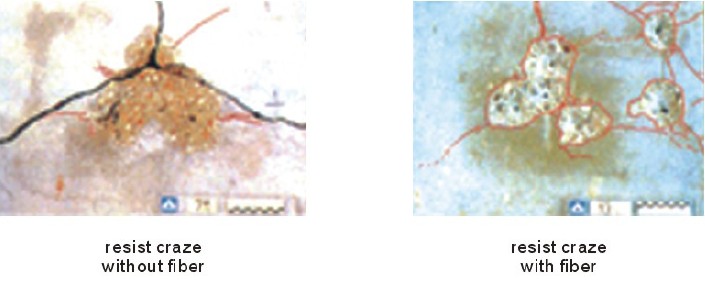

Crack Test on 14.5% Zro2 AR Glassfiber roving:

Pallet Packing of 14.5% Zro2 AR Glassfiber roving:

1. Each pallet has 3 or 4 levels ,16rolls /level. 860-1150kg/pallet.

2. 20pallets/1x20”GP 17-20MT/1x20’GP

- Q: I'm trying to install a handrail on a small set of concrete stairs. I drilled/chiseled two 3 inch deep holes for the newel posts. Do I simply put the posts in and add the cement? My fear is that once the cement dries, the cemented newel post quot;plugquot; will not adhere and be able to be pulled out of the hole. Do I have to do anything special to make sure this doesn't happen?

- The answer depends in part upon what type of soil you have. If you live on the Gulf Coast where the soil has a large clay characteristic to it, you need to bury the post 3' deep. This is because the soil will shift as it expands and contracts with the moisture content. When this happens the fence will sag. Look at your neighbors fences to see if this is a problem with their fences. If they are leaning......then deeper is better.

- Q: how is cement, concrete, mortar and glass made and used?

- see that window ? thats how glass is used

- Q: I am planning on laying vinyl sheet flooring in my kitchen floor. Can I use cement backer board as an underlayment.

- Laying Vinyl Flooring

- Q: bouncing the ball on the cement first then change to bouncing the ball on the carpet to see which floor the ball bounces the highest is my independent Variable the carpet? Is the dependent Variable the lower bounce on the carpet. Is the controlled variable the quality of the carpet

- How high your ball bounces is dependent on which surface you bounce it on. The height that you drop it from is the controlled variable as well as using the same ball.

- Q: He is putting in new counters and he is stuck. Please, your answer should be something normally kept in a kitchen and within reach of a penninsula. Your choices are coffee accessories, baking items, grill utensils and a toaster.

- Hm. I think he should just stay stuck until you get home from work to teach husband a lesson about getting stuck while playing with concrete. Then, on your way home, stop by a construction site and pick up a jackhammer and get him out of there with that. Maybe he'll learn to call a professional next time. Silly men. But, if that won't do and you REALLY want him out of there, I'd say a butter knife, a pair of tongs, and some butter or cooking oil might get the job done.

- Q: I need to mix 25 pounds of cement for a garden project ( a large stepping stone). In the past I have found it really difficult and physically tough to get the cement mixed relatively quickly to get the cement poured in the mold. I am mixing in a mop bucket. Does anyone have any suggestions to make this project easier?

- Use a wheelbarrow. Its durable enough to take it and it can quite easily be hosed cleaned afterwards. When mixing concrete you don't have to be too exact with measuring. Use a round top shovel and in a ratio of about 1:2:4 (1 cement, 2 sand, 4 stone). So you can try it with 2 shovel fulls of cement, 4 shovel fulls of sand, and 8 shovel fulls of stone. Blend together. Add water to the consistency you desire.

- Q: What do I do? Is it harmful?

- Call the emergency vet.

- Q: i'm finding it quite confusing =/ thank you.

- Cement is a powder-like substance;consists of aluminium, silicates etc. manufactured in a klin. Mortar is mixture of cement and sand. It is used to join bricks in a wall. Concrete is a mixture of cement, sand and aggregate(small stones) used to construct beam and columns.

- Q: It's already cured for about 36 hours. Is there something i can do? Someone mentioned something about Hydraulic cement. ????????

- themes and video tutorials for men and women looking for landscape tips and inspiration about their own house. If you are a landscape gardening enthusiast of any kind, you should by Ideas4Landscaping, a package with many wonderful materials to stimulate task ideas.

- Q: What percent of garnet is in cement?

- There shouldn't be any garnet in cement. Portland cement (the most common one) is a mixture of roasted limestone, clay and gypsum. None of these rocks normally contain garnets.

1. Manufacturer Overview

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords