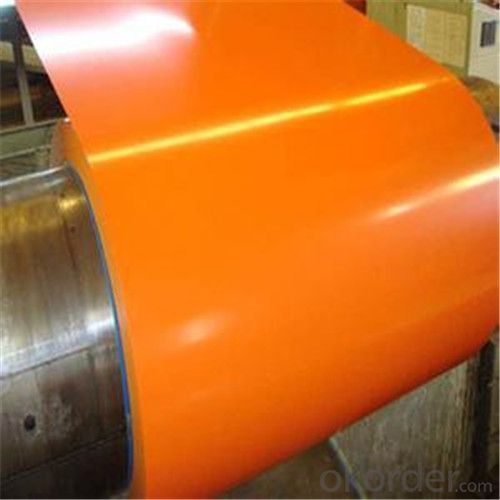

Z34 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Z34 BMP Prepainted Rolled Steel Coil for Construction

Description of Z34 BMP Prepainted Rolled Steel Coil for Construction

CR steel sheets have good processability, with good flatness and excellent surface, are available with different thickness and width combinations; are mainly used to manufacture the high value-added products in automotive and appliance, beverage packaging, electronic, electrcial moor and building etc. The CR steel sheet include the oncoated steel steel , galvanzied steel sheet, tin plate and TFS, precoated steel sheet and electrical steel steel, etc.

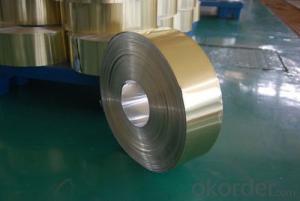

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Main Feature of Z34 BMP Prepainted Rolled Steel Coil for Construction

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3. Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle East, the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Applications of Z34 BMP PPGI Prepainted Rolled Steel Coil for Construction

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Z34 BMP Prepainted Rolled Steel Coil for Construction

Product | Z34 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z34 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: How do steel coils compare to other materials in terms of cost?

- Steel coils are generally more cost-effective compared to other materials due to their durability, versatility, and widespread availability in the market.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: How are steel coils protected against scratches and damage?

- To protect steel coils from scratches and damage, various methods are utilized. One widely used approach involves applying a protective coating or film to the surface of the coils. This coating acts as a barrier, preventing direct contact between the steel and potential sources of harm. It may consist of materials like polyethylene, PVC, or other abrasion and impact-resistant plastics. Moreover, steel coils are frequently wrapped or packaged using materials such as paper, cardboard, or plastic. This wrapping provides an additional layer of defense during storage, transportation, and handling. The wrapping material acts as a cushion, absorbing any potential impacts or friction that could cause scratches. Furthermore, special containers or pallets with protective features are employed to minimize the risk of damage to steel coils. These containers or pallets may have padded interiors, secure fastenings, or dividers that keep the coils in place and prevent them from rubbing against each other. In certain situations, steel coils are stored or transported in controlled environments to minimize damage. This may involve temperature-controlled warehouses or shipping containers that prevent the formation of moisture, which can lead to corrosion or other types of harm. Overall, a combination of protective coatings, wrapping materials, specialized containers, and controlled environments is utilized to ensure the adequate protection of steel coils against scratches and damage throughout their lifecycle.

- Q: I wanna strip down my bike and take off all the paint... im thinking of leaving it just the steal color... Do i need to put anythinng on the steel to coat it or can i just leave it like that... Will it rust or anything?

- If it's stainless steel or aluminum, it won't rust. Chances are the bike parts that have been painted are of metals that will rust. If you like the metal color, then you can get paints that look like metal or you can clear coat it. You might want to consider just a grey primer.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- It means they are hypoallergenic.

- Q: What are the factors to consider when selecting a supplier for steel coils?

- There are several factors to consider when selecting a supplier for steel coils. 1. Quality: The supplier's reputation for providing high-quality steel coils is crucial. The steel coils should meet industry standards and have consistent quality to ensure the durability and performance of the final product. 2. Reliability: It is important to choose a supplier that can consistently meet your demand for steel coils. They should have a proven track record of on-time delivery and the ability to handle large orders efficiently. 3. Cost: The pricing of steel coils is a significant factor to consider. While it is essential to find a supplier that offers competitive prices, it is equally important to ensure that the quality is not compromised. Comparing prices from multiple suppliers is advisable to find the best balance between cost and quality. 4. Range of Products: Look for a supplier that offers a wide range of steel coil products. This ensures that you have various options to choose from and can find the exact specifications and dimensions that meet your requirements. 5. Technical Expertise: A supplier with technical expertise and experience in the steel industry can provide valuable advice and assistance in selecting the right steel coils for your specific needs. They can also help with any customization or special requirements you may have. 6. Location and Delivery: Consider the supplier's location and their ability to deliver steel coils to your desired location. Choosing a supplier who is geographically closer to your facility can help reduce transportation costs and lead times. 7. Customer Service: A supplier who values good customer service is always preferable. They should be responsive to your inquiries, provide timely updates, and be willing to address any issues or concerns that may arise. By considering these factors, you can make an informed decision and choose a supplier that best meets your requirements for steel coils.

- Q: LIke a steel building conversion into a residental building??? Thanks.

- Right here. Steel Homes, Steel House, Steel Buildings, Steel Home Plans, ... Steel Homes, Steel House, Steel Buildings, Steel Home Plans, Steel Houses, ... Steel Homes and Buildings · Steel Office Buildings and Construction sites ... www.karmod.eu/steel-structures - 18k - Similar pages www.karmod.eu/steel-structures steel buildings metal buildings modular homes steel building ... ... log homes photographs, log homes construction, sales agents, log homes financing, ... Easy online pricing

- Q: What are the different types of steel coil edge conditions?

- There are several different types of steel coil edge conditions, each designed to meet specific requirements and applications. The most common types include: 1. Mill Edge: Mill edge is the default edge condition for hot-rolled steel coils, where the edges are left as they come out of the rolling process. This edge condition is characterized by a slightly rough and uneven surface. 2. Slit Edge: Slit edge is created by cutting the coil along its width to achieve narrower strips. This edge condition is typically smoother and more uniform than mill edge, making it suitable for applications where a clean and precise edge is required. 3. Trimmed Edge: Trimmed edge is achieved by removing irregularities and imperfections from the edges of the coil. This process results in a straight and smooth edge, making it suitable for applications where a precise and uniform surface is necessary. 4. Deburred Edge: Deburred edge is created by removing burrs or sharp edges from the coil. This edge condition is commonly used in applications where safety is a concern, as it eliminates any potential hazards associated with sharp edges. 5. Round Edge: Round edge is achieved by rounding the corners of the coil. This edge condition is often employed in applications where the material needs to be easily handled or when there is a need to prevent damage to other materials or surfaces. 6. Slit and Deburred Edge: Slit and deburred edge combines the benefits of both slit edge and deburred edge conditions. It involves cutting the coil to achieve narrower strips and then removing any burrs or sharp edges, resulting in a clean and safe edge. Each of these edge conditions serves a specific purpose and is chosen based on the requirements of the application. By understanding the different types of steel coil edge conditions, one can select the most suitable option to ensure optimal performance and safety.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

- Q: What is the current value of steel? Is it expected to increase in value?

- The steel in steel cents is the same as the steel in soup cans you throw out all the time. There is no sense in holding steel cents for their value as scrap. There are way too many steel cents around for them to ever have much numismatic value.

Send your message to us

Z34 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords