Xr5 High Density Polyethylene Geomembrane Black

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

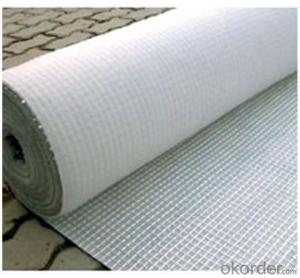

HDPE Geomembrane Description

HDPE geomembrane are made from High density polyethylene polymer by bolw film process .

Have Smooth surface , Textured surface , Anti-Skid suface

HDPE Geomembrane Main Function

Antiseepage and seperation

Geomembrane Property

1. Good flexibility

2. For service temperature range : -70℃ ~ +110℃

3. Corrosion resistance , aging resistance

4. Excellent environmental stress cracking resistance property

5. High tensile strength and elongation

HDPE Geomembrane Usage

Landfills , sewage or waste treatment seeage .

River bank , lake dam , dam , water dam and reservoir, channel , has liquid pool ( pit , mine )

Metro , basements and tunnels , tunnel seepage control lining Foundation and other foundation saline seepage

Embankment , upstream impervious blanket level , foundation vertical impermeable layer , cofferdam construction , waste disposal

Sea water , fresh water fish farm

Road , highway , railway foundation expansive soil and loess of the waterproof layer

Roof impervious

HDPE Geomembrane Specification

No. | Item | Test Value | |||||||||

0.75mm | 1.0 mm | 1.25 mm | 1.5 mm | 2.0 mm | 2.5 mm | 3.0mm | |||||

1 | Minimum Density(g/cm³) | 0.939 | |||||||||

2 | Tensile Property | ||||||||||

Yield Strength ,N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||||

Break Strength ,N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | ||||

Yield Elongation ,% | 12 | ||||||||||

Break Elongation ,% | 700 | ||||||||||

3 | Tear Resistance N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | |||

4 | Puncture Resistance N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | |||

5 | Stress Crack Resistance, hrs | 300 | |||||||||

6

| Carbon Black | ||||||||||

Carbon Black Content, % | 2.0-3.0 | ||||||||||

Carbon Black Dispersion | Carbon black dispersion(only near spherical agglomerates) for 10 different views 9 in categories 1 or 2 and 1 in category 3 | ||||||||||

7

| Oxidative induction time(OIT) | ||||||||||

Standard OTI Min | 100 | ||||||||||

High Pressure OTI Min | 400 | ||||||||||

8 | Oven aging at 85℃ | ||||||||||

Standard OIT-% retained after 90 days | 55 | ||||||||||

High pressure OIT-% retained after 90 days | 80 | ||||||||||

9 | UV Resistance | ||||||||||

Standard OIT retained after 1600 hrs | 50 | ||||||||||

High pressure OIT retained after 1600 hrs | 50 | ||||||||||

10 | Low tempreture impact brittle property at -70°C | Pass | |||||||||

11 | Water vapor permeability (g.cm/cm2 .s.Pa) | ≤1.0×10-13 | |||||||||

12 | Dimensional Stability (%) | ±2 | |||||||||

HDPE Geomembrane Roll Size:

Thickness | Width | Length | Remark |

0.5mm | 5.8m ( Standard ) | 50m - 400m | The standard width is based on the max loading quantity according to the container size . It’s will be loading more quantity to save Freight cost .

For other types also could be produce as request , the exact package will send to you driectly . |

7.0m | 50m - 400m | ||

7.5m | 50m - 400m | ||

8.0m | 50m - 400m | ||

1.0mm | 5.8m ( Standard ) | 50m / 100m / 150m | |

7.0m | 50m / 100m / 150m | ||

7.5m | 50m / 100m / 150m | ||

8.0m | 50m / 100m / 150m | ||

1.5mm | 5.8m ( Standard ) | 50m / 100m / 140m | |

7.0m | 50m / 100m/ 140m | ||

7.5m | 50m / 100m/ 140m | ||

8.0m | 50m / 100m/ 140m | ||

2.0mm | 5.8m ( Standard ) | 50m / 100m | |

7.0m | 50m / 100m | ||

7.5n | 50m / 100m | ||

8.0m | 50m / 100m |

Packaging & Delivery

| Packaging Details: | Woven fabric |

| Delivery Detail: | whthin 20days after received deposite |

F&Q

1. Can you send samples to us ?

Yes , free samples could be provided , but customer need pay for the freight cost .

After order placed , the freight charge could be refund .

2. What’s your Payment term ?

T/T , L/C

3. What’s your delivery method ?

By sea , By train , etc

4. Waht's your MOQ quantity ?

MOQ is one 20'container , the quantity could be negotiable .

- Q: Is non-woven composite geomembrane same to geomembrane?

- the mixed application of geotextile and geomembrane reaches the engineering requirements. Firstly, introduce geotextile: Geotextile is a kind of new construction materials in civil engineering, silk or short fiber are paved in nets through equippments and technology, then the needle puncture technology will make fabrics interwoven together, making the fabric standardization, making the fabric soft, full, thick, hard and satisfy the thickness requirements, short fiber geotextile or short fiber geotextile's tear-resistance strength is higher than short fiber. fiber is soft and has certain tear-resistance ability. main function: Filtration, drainage, reinforcement function specification 100 grams per square meter, 800 grams per square meter, it's main material polyester fiber has excellent water permeability, filtration, durability and ability to adapt to deformation, and surface drainage capacity. geomembrane plastic film as seepage-proof base material, the seepage-proof performance of non-woven composite soil engineering impermeable material, two cloths and membranes mainly depends on the seepage-proof performance of plastic film. geomembrane is a kind of flexible?material polymeride basic material, high waterproof material proportion, good extensibility,high?adaptability?to the?deformation, corrosion resistance, low temperature resistance, frost resistance.

- Q: can geomembrane reach A-class seepage-proof?

- the seepage-proof effect of project composite geo-membrane is mainly depends on the interlayer, the norms of seepage-proof geomembrane is 100-1500g/square meter, in order to guarantee the good seepage-proof effect, the thickness of geomembrane should be less than 500g/ square meter, outer geotextile should be less than 300g, too thin geotextile will reduce the sand stone resisting effect, increasing geomembrane's thickness and prevent sand stone corrosion will influence the seepage-proof effect of geomembrane, composite geo-membrane's norms is less than 800g/square meter, which can reach the seepage-proof standard.

- Q: How do geomembranes prevent soil contamination in oil and gas industry applications?

- Geomembranes prevent soil contamination in oil and gas industry applications by serving as a barrier between the soil and any potential contaminants. These impermeable liners are designed to prevent the migration of pollutants, such as hydrocarbons, from reaching the soil and groundwater. By effectively containing and isolating hazardous substances, geomembranes ensure that the surrounding environment remains protected from potential contamination.

- Q: What are the requirements for geomembranes used in fish ponds?

- The requirements for geomembranes used in fish ponds typically include being durable, impermeable, and resistant to UV radiation, chemicals, and punctures. They should also be able to withstand the weight of water and have a smooth surface to prevent damage to the fish and their habitat. Additionally, the geomembranes should be non-toxic and safe for the fish and the environment.

- Q: What are the considerations for geomembrane selection in oil and gas exploration sites?

- Some considerations for geomembrane selection in oil and gas exploration sites include the chemical resistance of the geomembrane to potential contaminants found in the soil or water, the strength and durability of the material to withstand the harsh conditions of the site, the flexibility of the geomembrane to conform to irregular surfaces, and the overall cost-effectiveness of the chosen material. Additionally, factors such as installation requirements, environmental regulations, and the project timeline may also influence the selection process.

- Q: Imported geomembrane imported anti seepage film width.

- Geomembrane is generally six meters wide. it can be up to 8 meters.

- Q: What is the role of the geomembrane?

- The full name of geomembrane is "high density polyethylene", with excellent property of environmental stress cracking resistance, low temperature resistance, aging resistance, corrosion resistance, larger using temperature range(-60--+60) and longer service life for 50 years. It is widely used in anti-seepage projects such as landfill of life waste,solid landfill, sewage treatment plant, artificial lake, and tailings treatment.

- Q: How do geomembranes contribute to flood control measures?

- Geomembranes are synthetic liners that are used to contain and control water flow. In flood control measures, geomembranes play a crucial role by acting as barriers to prevent water from seeping into the ground or leaking through structures. These liners are installed in various flood control structures such as dams, levees, and channels to enhance their effectiveness in containing floodwaters. By providing a reliable and impermeable barrier, geomembranes help to reduce the risk of water infiltration and protect critical infrastructure, thus contributing significantly to flood control measures.

- Q: Is geotechnical membrane dedicated KS glue poisonous?

- This is non-toxic. Generally, fish pond, shrimp pool, reservoir paving impermeable geomembrane construction would use geomembrane special adhesive, because it is cheaper than welding, convenient and simple.

- Q: How do geomembranes provide water retention in rooftop gardens?

- Geomembranes provide water retention in rooftop gardens by acting as a barrier between the garden soil and the rooftop surface. They prevent water from seeping through the roof and provide a waterproof layer, ensuring that the water remains within the garden area. This allows for efficient water management, reduces water runoff, and keeps the plants adequately hydrated, promoting healthy growth in the rooftop garden.

Send your message to us

Xr5 High Density Polyethylene Geomembrane Black

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords