WPC Prefab Houses Wood Plastic Composite Deck board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of WPC Prefab Houses:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

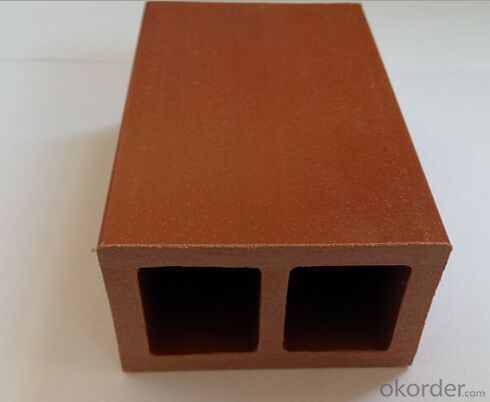

Composition of WPC Prefab Houses:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of WPC Prefab Houses:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

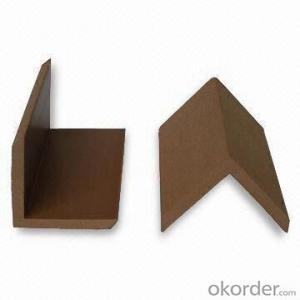

Installation of WPC Prefab Houses:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of WPC Prefab Houses:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, formaldehyde removal method of Han purple is physical adsorption by palygorskite and sepiolite based, adding diatomite, tourmaline and other natural minerals, after special processing technology is made, in which the pore pore size between 0.27 - 0.98 nm and a crystal arrangement. At the same time is weak, formaldehyde, ammonia, benzene molecules, toluene and xylene in diameter 0.40.62 nm, and it is a polar molecule, so it has the features of preferential adsorption of formaldehyde, benzene, TVOC and other harmful gases, to purify indoor air effect

- Q: How about the plastic floor?

- Exactly the PVC floor. Not everyone understands the normal plastic. Many advantages. At present, foreign market point eighty percent. Domestic began. Many people don't know yet. Many advantages:

- Q: Plastic floor to allow welding joints

- Hot welding: when the elastic floor is completed, the use of special material with the elastic floor material, according to the type of material to adjust the temperature of hot welding. The hot welding makes the two sides of the floor seam uniform.

- Q: Heard that there is a special plastic floor nursery? What are the benefits

- Kindergarten special plastic floor is very popular now, the benefits are: 1, the green environmental protection: the kindergarten plastic floor 100% new environmental protection material: PVC, does not contain formaldehyde, does not contain asbestos, lead, mercury and other harmful heavy metal filler, fully meet the needs of children of green space.

- Q: Plastic foam on the floor there is no effect of moisture

- In addition to pad plastic film surface is generally relatively thick, so it will not easily deteriorate, generally do not have what problem, whether it is solid wood or composite floor now installed under the floor are used in this material. Mat close to laying on the ground, a waterproof, moisture-proof, protect the floor, increase the elasticity of the film, the ideal thickness is more than 0.22mm, and has the properties of alkali resistant, acid resistant.

- Q: Plastic floor glue how shop, suitable for use at home

- The material is of high wear-resistant floor rubber products, the main types of floor glue is too much, please choose the site of special products, if you are a family choose stone plastic sheet, choose the mall commercial airport pure material, rubber flooring, floor board special dance dance, rubber floor has a high requirement for the quality of the ground, the ground should be flat. No sand, dry ground, ground cracks, no different use requirements, main floor glue fire, anti-skid, environmental protection, easy to clean, variety, fast construction, long service life, our factory production of the special plastic Mio dance floor, if so we can provide samples for reference, to the membrane of different thickness different price you want, our dance floor (dance floor, many kinds of special).

- Q: What is the material of the plastic foam plate

- Plastic foam floor: the name of the PVC plastic floor, the main material for the PVC resin. Commonly used into four categories, different types of additives are not the same

- Q: What is the plastic floor, what is the plastic floor

- But more joints, construction speed is slow. The main advantages of floor leather: laying speed, less seams. For thicker coil, can be used directly on the base without adhesive. However, local damage repair inconvenience, all replace and waste a lot of materials.

- Q: Is plastic floor glue toxic? Thank you

- Floor leather (toxic, mainly heavy metal exceed the standard): this kind of floor in black or dark bottom. Because of cheap, from 80s in China's mass production and application. Especially in the three northeastern provinces, a large number of people in the home are useful, with the promotion of commercial land in recent years, is now being reduced, and now the market is very environmentally friendly sales standards. Some are not under the environmental protection, but the surface is environmentally friendly, if there are children at home do not recommend the use of the more can not be used to artificial food mat

- Q: Home decoration, floor requirements should be very flat

- Hello, like now is winter, low temperature period should pay special attention to prevent the occurrence of bad construction measures

Send your message to us

WPC Prefab Houses Wood Plastic Composite Deck board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords