Wood Plastic Composite Solid Decking for prefect project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Forestar WPC offers WPC decking with outstanding quality, best service and competitive price.

FORESTAR WPC SOLID DECKING OF 146*20MM

FEATURES AND ADVANTAGES:

Outstanding Characters

• Dimension stability

It will not be out of shape after a long testing of 10 years and there is no crack under the test temperature between -40°c to 60°c

• Material Safety

Low flame spread / High slip resistance / No sting of wood / Contains no toxic chemicals or preservatives / Environmental friendly / Can be recycled with 100%

• High Strength

Outstanding screw and nail retention / High impact resistance / Great Compressive-tensile-shear strength / Modulus of elasticity: 20% greater than PVC

• Good appearance & nice touch

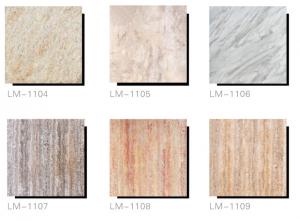

Natural feel & wood touch / Broad range of finishes and appearance, Multicolor, and needn't to painting

• Longevity

Its lifespan at least 10-15 years in the outdoor weather condition

• Install & Maintain easily

Easy to produce and easily fabricate / Easy to cut, fix and glue; Easy to tenon, drill and nail / Require less routine maintenance / No need staining & water Sealant

Competitive Price

• Using most advanced machinery to increase the output and reduce the costs.

Strong technical support from famous institute of high polymer to guarantee the best quality as well as cost saving.

• Neighboring one of the biggest wood/ bamboo processing industry region and having a special purchase channel of the raw materials (Plastic and wood/bamboo fiber)

• As a high technology and environmental-friendly enterprise, supports form the government such as reduction and exemption of tax rate are available.

INGREDIENT Forestar WPC products are made of:

• 60% Bamboo/wood powder

• 28% Recycled HDPE/PP/PE/PVC powder

• 12% Chemical additives such as colorants, coupling agentsstabilizers, sreinforcing agents, foaming agents, lubricants, anti-UV agent, Anti-oxidation agent and anti fungus agent.

component of chemical additives may alter a little from different products adapting to different physical/ chemical demands.

FORESTAR'S BELIEF

In manufacturing products made entirely from waste plastics and waste wood, we have demonstrated our commitment to a number of crucial objectives.

• To ensure our products always exceed expectations of the purposes for which they are intended. To create products that are much more endurable than those made from conventional material.

• To constantly improve our technology to ensure the maximum amount of waste can be recycled.

• To minimize wastage in our manufacturing processes.

• To conserve precious natural resources.

• To provide customers the option of a new and update products, rather than something our previous customers asked for.

- Q:What is the plastic floor and what is the compound floor?

- PVC floor, laminate flooring and other surface has three oxidation of two aluminum wear-resistant layer, more resistant to burning, the general bamboo, wood floor surface is painted, not resistant to burning cigarette butts.

- Q:Plastic floor joints how to deal with?

- Cold welding: when the plastic floor laying is completed, the use of cold liquid, cream or cold welding to connect floor seam.

- Q:What is a plastic floor?

- The plastic floor is very popular in the world today a new light ground decoration materials, also known as the "light body material" in Europe and Asia, Japan and South Korea are popular, popular abroad, from the beginning of 80s to enter the China market, it has been widely accepted in the domestic large and medium-sized city

- Q:What is the difference between plastic floor and floor leather? What is the wear resistance of plastic floor? How to distinguish the quality of plastic flooring?

- Floor leatherThese two kinds of materials due to the very simple and inexpensive, had a few years ago, the rage. But because of tile retrofit and composite wood flooring, floor leather is so beautiful as before. Now choose more for rent and borrow a house, but it does not mean that the floor has come to an end: a new type of floor leather has been published, it is similar to the marble and granite pattern, color is more diverse, texture is better than the traditional floor leather, but it is more than and 100 yuan the price per square meter is not so ", so the family decoration amiable and easy of approach" is not very much in.

- Q:How about the plastic floor?

- 7 international development has been for 60 years, China only for the past 15 years.8, recycling, reduce resource consumption.

- Q:How to deal with the plastic foam on the floor?

- How to deal with the plastic foam on the floor?

- Q:Basketball court assembled plastic floor why pack

- The main thing is that you choose the floor quality is not good. Do not choose the floor of Hebei, Zhejiang, the use of PP material is too bad, you can consider the manufacturers in Guangzhou: love fantastic speed lattice 02, CELINE Seg, Yin Chi sports Bert, Rio sports LT

- Q:How can a lot of plastic cloth stick on the wood floor?

- Remove the protective layer of the outer surface of the furniture, only the manual removal is the most convenient and effective method, with other things can easily hurt the appliance.

- Q:What is the difference between plastic floor leather and plastic floor tile

- Floor leather is a kind of soft plastic floor general, only two layers of plastic, not wear-resisting layer, easy aging deformation, heavy pressure after formation of indentation can not be restored, and is not easy to electrostatic fire

- Q:How much is a normal plastic floor

- PVC floor, also known as plastic flooring, different regions are also different names. Prices generally in 28-500 yuan / square meter. According to the local situation to locate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Solid Decking for prefect project

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 800 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords