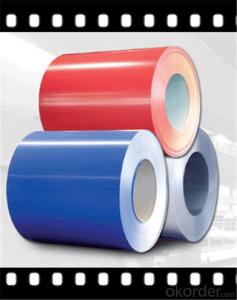

WOOD0109 Steel Coil PPGI CNBM

- Ref Price:

-

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Quick Details

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Thickness: | 0.17mm-0.8mm |

|

|

| Brand Name: | PU YIN | Type: | Steel Coil | Technique: | Hot Rolled |

| Width: | 800mm-1250mm | Length: | to your requirements |

|

|

Packaging & Delivery

| Packaging Details: | Oscillated wound: one coil per bundle, inner is the protecting humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) |

|---|

| Delivery Detail: | Depends on specification and order quanity. |

|---|

Feature

(1) Regular spangle, minimized spangle and skin-pass.

(2) Chromate and Chromate-free passivation.

(3) Oiled and unoiled. Specifications

| BASE MATERIAL | (1)HDGI (2)ALUZINC (3)CR (4)ALUMINUM |

| GRADE | SGCC, DX51D, ASTM A653, EN10142, S350GD,etc. |

| THICKNESS | 0.18mm-0.80mm |

| WIDTH | ≤1250mm |

| ZINC COATING | 60-200g/m2 |

| PATTERN | Wood,Marble,Hairline,Brick,and Camouflage series,etc. |

| PAINT | PE,PVDF,SMP,HDP |

| COIL ID | 508mm |

| COIL WEIGHT | ≤6t |

What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: what is magnetic steel used for and if it can be used for producing kitchenwares utenils like stainless steel basines,mugs and bowls.

- Magnetic steel rusts. That's why kitchenware is often made out of stainless. You can't turn magnetic steel into stainless, sorry. Metalurgy is a complicated subject, and is all about different alloys. It's far too involved to explain in a few paragraphs here, but no, they're not interchangeable in this case unless you want to produce kitchenware that rusts.

- Q: i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- earlier you circulate approximately any extensive alterations, take the guitar to a qualified technician and notice approximately having the strings, or action diminished nearer to the fretboard. this could take very numerous soreness off of his palms, because it feels like the guitar hasn't been set-up in any respect, or a minimum of superb. A neck adjustment, if mandatory, might additionally help this issue. If he continues to be experiencing finger soreness (he might might desire to undergo some), attempt a lighter gauge set of strings (steel). a good tech can help you there, too. Nylon strings are not going to paintings properly in any respect on a non-classical guitar; the parameters are in basic terms different adequate between the two certainly one of them to end not something greater suitable than to waste your money. the main uncomplicated issue I see on a conventional foundation is that guitars are offered and offered without suitable set-up. An experienced tech will examine the neck configuration; the bridge alignment; saddle top; venture end; nut clearance; and action on an acoustic guitar. There are much greater info on an electric powered. Please detect a music/guitar save that does this form of paintings on the premises. My concept is that the finished relatives will income. Cheers decrease back atcha!

- Q: How are steel coils used in the construction of bridges?

- Steel coils are an essential component in the construction of bridges. These coils are typically made from high-strength steel and are used for various purposes throughout the bridge-building process.

One of the primary uses of steel coils in bridge construction is for manufacturing structural components. These coils are cut, shaped, and welded together to create beams, columns, and trusses. These structural elements provide strength and support to the bridge, ensuring its stability and durability.

Steel coils are also used in the fabrication of bridge decks. These decks are the upper surface of the bridge, providing a roadway for vehicles and pedestrians. The coils are rolled into sheets and then further processed to create the deck plates. These plates are then assembled and attached to the bridge's structural components.

Another important application of steel coils in bridge construction is for reinforcing concrete structures. Rebar, which is short for reinforcing bar, is made from steel coils and is embedded within the concrete to enhance its strength and resistance to tension. The rebar is typically placed in strategic locations, such as within the bridge piers and abutments, to provide additional support and prevent cracking or collapsing.

Additionally, steel coils are used for manufacturing bridge expansion joints. Expansion joints are critical components that allow bridges to expand and contract with temperature changes and other external factors. These joints are made using steel coils, which are formed into plates or strips that can be easily installed and adjusted to accommodate the bridge's movement.

In summary, steel coils play a crucial role in the construction of bridges. They are used for manufacturing structural components, bridge decks, reinforcing concrete structures, and expansion joints. Steel coils provide the necessary strength and support required for building safe and reliable bridges that can withstand various loads and environmental conditions.

- Q: How hot does steel have to get before it will melt?

- Type your query into Yahoo! Search or other search engines to get the answer: It depends, since steel usually has different metals added for various properties (strength, corrosive resistance, etc.)

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- pl. be specific about the type of steel: (Steel is a metal alloy whose major component is iron, with carbon content between 0.02% and 1.7% by weight. Carbon is the most cost effective alloying material for iron, but many other alloying elements are also used.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and their distribution in the steel controls qualities such as the hardness, elasticity, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also more brittle. The maximum solubility of carbon in iron is 1.7% by weight, occurring at 1130° Celsius; higher concentrations of carbon or lower temperatures will produce cementite which will reduce the material's strength. Alloys with higher carbon content than this are known as cast iron because of their lower melting point.[1] Steel is also to be distinguished from wrought iron with little or no carbon, usually less than 0.035%. It is common today to talk about 'the iron and steel industry' as if it were a single thing; it is today, but historically they were separate products. Currently there are several classes of steels in which carbon is replaced with other alloying materials, and carbon, if present, is undesired. A more recent definition is that steels are iron-based alloys that can be plastically formed (pounded, rolled, etc.). Iron alloy phases : Austenite (γ-iron; hard) Bainite Martensite Cementite (iron carbide; Fe3C) Ferrite (α-iron; soft) Pearlite (88% ferrite, 12% cementite) Types of Steel : Plain-carbon steel (up to 2.1% carbon) Stainless steel (alloy with chromium) HSLA steel (high strength low alloy) Tool steel (very hard; heat-treated) Other Iron-based materials : Cast iron (2.1% carbon) Wrought iron (almost no carbon) Ductile iron)

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Steel coils are commonly used in the manufacturing of automotive accessories due to their strength, durability, and versatility. These coils serve as the primary raw material for various components and parts used in the automotive industry.

One of the most common uses of steel coils in automotive accessory manufacturing is for the production of body panels and frames. These coils are formed and shaped into the desired size and design, and then undergo various processes such as cutting, stamping, and welding to create the body panels and frames of vehicles. The high strength of steel coils ensures that the body panels and frames are sturdy enough to withstand the rigors of daily use and provide the necessary structural integrity to the vehicle.

Additionally, steel coils are also used in the production of automotive suspension systems. Coil springs, which are integral components of the suspension system, are typically made from steel coils due to their ability to absorb and distribute the weight and impact of the vehicle. These coil springs contribute to a smooth and comfortable ride by providing the necessary support and shock absorption.

Furthermore, steel coils are used in the manufacturing of automotive accessories such as exhaust systems, brackets, and brackets for various components. The coils are formed and shaped into the required design and then undergo processes like cutting, bending, and welding to create these accessories. The strength and durability of steel make these accessories capable of withstanding high temperatures, vibrations, and other harsh operating conditions.

In summary, steel coils play a crucial role in the manufacturing of automotive accessories by providing the necessary strength, durability, and versatility required for various components and parts. From body panels to suspension systems and accessories, steel coils contribute to the overall quality, performance, and safety of automotive accessories.

- Q: How are steel coils stored to prevent damage?

- Steel coils are typically stored in a way that prevents damage and ensures their integrity. One common method is to stack the coils in a horizontal position. This helps distribute the weight evenly across the coils, minimizing the risk of deformation or damage. In addition, wooden or steel dunnage is often placed between each layer of coils to provide support and prevent them from shifting during storage or transportation.

To further protect the coils from damage, they are often stored indoors or in covered areas to shield them from exposure to the elements. This helps prevent rusting or corrosion, which can compromise the quality of the steel. If outdoor storage is necessary, the coils may be covered with weather-resistant tarps or protective coatings to minimize the impact of rain, snow, or sunlight.

Furthermore, it is important to consider the stacking height to prevent excessive pressure on the lower coils. To avoid damage, coils are typically stacked in a way that ensures the weight from the upper layers is distributed evenly across the lower ones. This can include using specialized stacking equipment or racks designed to handle the weight and dimensions of the coils.

Overall, proper storage of steel coils involves careful consideration of weight distribution, protection from the elements, and minimizing contact between coils to prevent damage and maintain their quality.

- Q: i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- This Site Might Help You. RE: is stainless steel and surgical steel the same? i need the same kind of body jewelry they use in the piercing shop but when i go to order them they say stainless steel, not surgical steel, and i have REALLY sensitive skin so i need to be sure, whats the difference?

- Q: Ok, so im gonna get my tragus pierced and i was wondering which is better, titanium or stainless steel. I hear like everyone uses stainless steel , but is titanium better?Thanks

- Titanium is better, and most piercings heal better with titanium used jewellery.

- Q: What are the common coil defects and their causes?

- Common coil defects can include misshapen coils, coil breaks, and coil slippage. Misshapen coils can be caused by improper winding tension or uneven material thickness. Coil breaks may occur due to excessive tension during winding, inadequate material strength, or improper handling. Coil slippage can result from insufficient binding or improper tension control. These defects can affect the performance and integrity of the coil, leading to potential issues in its functionality.