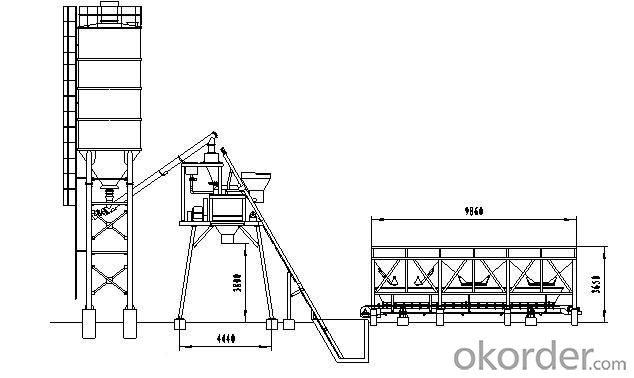

WCQ300G Stabilized Soil Mixing Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stabilized soil mixing plant is special mixing plant for achieving the continuous even mixing of a variety of stabilized road base materials with high batching accuracy (in accordance with the requirements of raw materials), it is widely used in the construction work for road, airport, dock and other construction projects.

Its components include an aggregate supply measuring system, powder supply measuring system, water supply system, mixing device, storage device and control system.

Our stabilized soil mixing plant uses a durable twin-shaft mixer for excellent performance and high efficiency, it can mix various kinds of materials (including cement) and make all types of stabilized soil, and its productivity is 300-600t/h;

The plant is compact and modular designed for easy installation and movement, and containerized transportation is optional;

Computerized control system and electronic weight system gives high degree of automation and batching accuracy, and the plant can be switched between manual operation and automatic operation.

PRODUCT DETAILS

![]() Modular Container Type Batching System

Modular Container Type Batching System

![]() The number of batching bins is determined by the requirements of our customers.

The number of batching bins is determined by the requirements of our customers.

![]() The device is easy to install and dismantle, enabling easy movement when relocate.

The device is easy to install and dismantle, enabling easy movement when relocate.

![]() The aggregate conveyor belt scale and mixture conveyor are pre-adjusted in order to save the installation time.

The aggregate conveyor belt scale and mixture conveyor are pre-adjusted in order to save the installation time.

![]() Mixing System

Mixing System

![]() The system has an advanced no-scale-board forced twin-shaft continuous mixer.

The system has an advanced no-scale-board forced twin-shaft continuous mixer.

![]() The specific discharging port on both sides and at bottom of mixer makes it convenient and easy to clean.

The specific discharging port on both sides and at bottom of mixer makes it convenient and easy to clean.

![]() The special wear-resistant alloy blades greatly increase its durability.

The special wear-resistant alloy blades greatly increase its durability.

![]() A lengthened mixing shaft and well-distributed mixing blades facilitate thorough and even mixing, eliminating the problem of material isolation.

A lengthened mixing shaft and well-distributed mixing blades facilitate thorough and even mixing, eliminating the problem of material isolation.

![]() Cement Storage, Supplying and Measuring System

Cement Storage, Supplying and Measuring System

![]() Cement Storage and supplying

Cement Storage and supplying

Customized configurations of cement silos are available. We can provide 50 ton, 80 ton, 100 ton and other sizes of cement silos according to your requirements. Single silo, double silo and multiple silos are also available. Based on silo configurations, the user can choose single measuring or separate measuring modes.

Besides, there are bagged cement conveying systems, bucket elevators and other accessories for our clients to choose. You special design requirements can also be satisfied.

The enlarged cement discharging port can prevent cement from arching, thus making the measurement more accurate. And pneumatic arch-broken devices are installed to ensure continuous and accurate measurement.

![]() Cement Measuring Device

Cement Measuring Device

The cement measuring device is made up of an overflow reamer and a measuring reamer.

The overflow reamer has a large charging port, which ensures continuity and stability of cement conveying. The overflowing structure of discharging port ensures that the material fall continuously and evenly, thus helping to make accurate measurements.

Measuring reamer adopts a suspended structure, and is not influenced by external conditions. Sensor, PLC, computer and frequency converter constitute a whole set of an efficient measuring control system. When certain parameters are calibrated, the control system can automatically carry out accurate measurements.

SPECIFICATION

Model | WCQ300G | |

Output(m3/h) | 300 | |

Mixer | Mixing Power (kW) | 2×22 |

Aggregate Size (mm) | ≤50 | |

Dosing Tank Volume (m3) | 4X9 | |

Belt Conveyor Conveying Capacity (ton/h) | 400 | |

Weighing Range and Accuracy | Aggregate (Kg) | ±2% |

Cement (Kg) | ±1% | |

Water (Kg) | -1%~+2% | |

Total Power (kW) | 106 | |

Discharge Height (m) | 3.6 | |

- Q: I am a manufacturing engineering technology and a mechanical engineering double major and am wanting to know how I can go about designing and building automobiles, ships, or heavy construction machinery. What kinds of companies should I be looking at? and what qualifications should I be shooting for?

- No individual can design and build automobiles, ships, or construction machinery. You can be a specialised member of a team to design parts of automobiles, ships, or construction machinery.

- Q: why Singapore import machinery and equipment, mineral fuels, chemicals?

- I lived in Singapore for a month, so my answer for you is a reflection of that experience and what I learned there (briefly) from talking with some co-workers. Singapore is a wonderful little country that is in between several economic powers - Malaysia, Indonesia (the 5th largest country in the world), China, Japan and the Koreas; (but you know all that already) - It is a very favorably positioned and accessible seaport. These trading policies were undoubtedly part of the policies of P.M. Lee Kuan Yew. It is a very active, willing and cooperative trade partner and in return gets great deals on imported goods from sea trade in return for favorable trading terms. I personally would love to live there, but the heat and humidity are too much for me to make that decision. HTH

- Q: What are the listed companies of construction machinery in China? What are the shares of A?

- Listed companies report you can log on the Shanghai stock exchange and Shenzhen stock exchange website, in the information disclosure of periodic reports below can be found in the name and code, the construction machinery companies in the picture below.

- Q: What are the major of construction machinery application and maintenance?

- This graduate jobs are mainly three aspects: 1, engineering machinery manufacturing enterprises, such as Sany, XCMG, ZOOMLION, Xiamen, manufacturing and assembly production line.

- Q: what is the main functions of hydraulics in a machinery?

- to move parts

- Q: A guy my husband works with has a fellow employee that operates a crane and him and his crane are the only cranes on the entire work site that a whole flock of bees in attracted to and he has gotten stung many times already and wants to know of anything natural or not that is cheap and easy that could repel the bees away. help plz...

- Are you sure that's not a yellow-jacket nest? They are aggressive near the nest, it's often under-ground. They're pests and can be sprayed with a clear conscience. There are 'knock down' products sold for use by line-men who often have to deal with nests. Find and spray the nest entrance. It can be done from quite a distance at first. Bees are threatened, ecologically valuable, and should be protected as Mike suggests.

- Q: Is repairs to plant and machinery revenue or capital expenditure???? Can you all explain why?????and what is the different between revenue or capital expenditure!!!1

- Start okorder

- Q: Our teacher has specifically asked us to search for the ACM definition of computer science, as well as its elements. I've been looking all over, but to no avail. Anyone mind helping me out?

- Computer Science Definition

- Q: Is your front end loader considered heavy machinery?

- Some of the ladies here have nice front end loaders. Some are bigger than others. Some have none Some have huge cabooses.

- Q: how to produce biodiesel from agricultural products? Technical anf machinery?

- Either your grow an oilseed, extract the oil and make biodiesel from the oil. Or you do some form of pyrolysis, to get liquid fuel. Or you do pyrolysis to make syngas and you make diesel similarly to how the Germans did in WWII. All the techniques and machinery are pretty easy to find on the web depending on which you want to do. On a small scale, the oil and use and alcohol with a catalyst to make biodiesel is likely the easiest. The Dakota Gasification plant cost 4.5 billion dollars when it was constructed back in Jimmy Carter's time. It uses coal to make either natural gas or syngas which is used to make anhydrous ammonia. A plant to use ag products would be similar. Marv

Send your message to us

WCQ300G Stabilized Soil Mixing Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords