HLS300 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

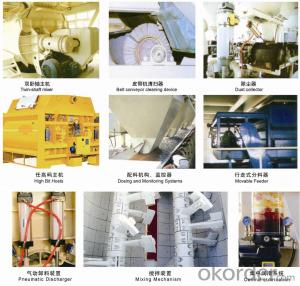

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS300 | |

Production capacity (m3/h) | 300 | |

Concrete mixer | Model | JS5000 |

Power (kW) | 2×75 | |

Output capacity (m3) | 5 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | underground bin |

Belt conveyor deliverability (t/h) | 1000 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(5000±2%) |

Cement (kg) | 3000±1% | |

Fly ash (kg) | 1000±1% | |

Water (kg) | 1200±1% | |

Admixture (kg) | 100±1% | |

Discharging height (m) | 3.8 | |

- Q: Think about situations in which machinery is required to produce motion of some sort. Name two activities wh?

- a train engine produces motion for a train a car engine moves a car

- Q: I am doing an energy audit for a plastic manufacturing company for my final year university project.The company runs on 3 phase and has a large variety of different machinery (blow molders, injection molders, compressors, refrigerators etc) I am required to measure each component and determine how much is contributed to the monthly electricity bill. What is the best way to do this? Is there any pieces of equipment I can use (such as something similar to the kill-a-watt) which can attach to the machine and measure kW usage?The machines run on demand so therefore taking an average from the specifications would be too inaccurate.NEED SOME HELP PLEASE :(

- If it runs on demand, whatever you put down will be correct. Let them prove you wrong! Or you could guestimate how long they are used each day and take the nameplate power rating off the machine, then do the math.

- Q: how do i lose 50 lbs with out any heavy machinery?

- You can lose without any machinery 1kg=2.2lbs per week by using cellular nutrition which has 60 million unsolicited testimonials, in the last 26yrs

- Q: Question about jounal entry Purchased a machinery I have to affect this entry on purchase a/c as well as fixed assets also I want to take tax set off, How can I ?suppose I pass purchase entryParty / Purchase Dr. (Creditor)To Machinery Net 4% cr.(Purchase)To Vat 4% cr.(Duties Taxes) Fixed asset machinery Machinery a/c dr. (fixed assets)To party/ or purchase or what ?

- first of all alter the Machinery ledger and set it to yes in USE IT IN VAT RETURNS then in JOURNAL mode, make the entry as : Debit Machinery A/c and credit to the Party a/c

- Q: Back in college a Friend told about this idea that we try to create things in our own image (take this as you will)first is fire, something with formnext is tools, something that is solidthen a machine, something that movesthen an automatic machine, something that moves on it's ownSo given that one of those three must be next, something that thinks, something that takes commands, or something that is made of the same thing we are?

- Artificial intelligence has successfully been used in a wide range of fields including medical diagnosis, stock trading, robot control, law, scientific discovery, video games and toys. Frequently, when a technique reaches mainstream use it is no longer considered artificial intelligence, sometimes described as the AI effect. It may also become integrated into artificial life.

- Q: Why do many medications caution the consumer not to operate heavy machinery?

- Cos of opium

- Q: What would be more delicate? A VCR's tape head or a DVD's lens? I don't mean the more older they are, the more fragile or delicate they would be but as in if they were manufactured in the same year, date and even the same second, what would be more delicated.PS; You might want to regard this question as a vote or an actual fact.

- In my opinion, the rotary video head is more delicate that the lens. First, it does come in contact with the tape, so can get damaged. Cleaning it improperly can damage it. A DVD lens does not contact the media in normal operation, and are pretty foolproof to clean.

- Q: And what does taking flu medicine have to do with perfoming operations?

- Medicine knocks u out during ur surgery and u dont feel a thing and and they put flu medicine because you have big cuts and after surgery you in a hospital and u could get anything in that hospital

- Q: one of stalin's acheivements was the creation of his elaborately bureaucratized administrative machinery based on the interlinking of the Communist Party, ministries, legislative bodies, trade unions, political police, and armed forces, and also on a host of other meshing control devices.What does this mean? thanks!

- It means that Stalin's cronies were put in positions of power in such a way that his authority spanned (linked) across the administrative offices of government, as you cite, so that he essentially controlled the USSR as though he possessed the only key.

- Q: too young, sick, drunk, high, crazy?

- a couple of nights ago.........that's the last time i do shrooms drink half a keg and then take a hand full of anti depressants which btw dont really work the way they are suppose to if your not depressed and have beer in your system

Send your message to us

HLS300 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords