HLS180 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

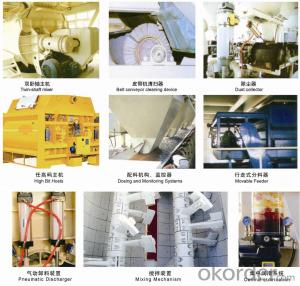

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS180 | |

Production capacity (m3/h) | 180 | |

Concrete mixer | Model | JS3000 |

Power (kW) | 2×55 | |

Output capacity (m3) | 3 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 30 |

Belt conveyor deliverability (t/h) | 800 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 4×(3000±2%) |

Cement (kg) | 1500±1% | |

Fly ash (kg) | 600±1% | |

Water (kg) | 600±1% | |

Admixture (kg) | 60±1% | |

Discharging height (m) | 3.8 | |

- Q: is a machinist, and someone who plays the piano is a pianist, is someone who races cars a racist?

- No. That is insulting.

- Q: i own my own construction and landscaping company and have 7 years experience in an excavator bulldozer and other pieces of heavy machinery.

- If you can afford to ship it and pay your airfare then you are wanted

- Q: What is mechanical engineering?

- Mechanical Engineering: mechanical engineering definition: an engineering discipline related to mechanical and power production. Applied disciplines: Mechanical Engineering (level one discipline); institutional (two discipline); general term of organization (level three discipline)

- Q: On December 31, 2012, Flint Corporation sold for $100,000 an old machine having an originalcost of $180,000 and a book value of $80,000. The terms of the sale were as follows:$20,000 down payment$40,000 payable on December 31 each of the next two yearsThe agreement of sale made no mention of interest; however, 9% would be a fair rate for thistype of transaction. (The present value of an ordinary annuity of 1 at 9% for 2 years is 1.75911.)Prepare the journal entry to record the sale of the machine.

- 40,000 x 1.75911 = $70,364 PV of note receivable Dr Cash 20,000 Dr Notes Receivable 70,364 Dr Accumulated Depreciation--Machine 100,000 Cr Machine 180,000 Cr Gain on Disposal 10,364

- Q: Registration process of a construction machinery maintenance plant in Tangshan? What information should be prepared and which departments should be handled?

- Nuclear Name: to Industrial and Commercial Bureau to obtain an "enterprise (famous) name pre approved application form", fill in your company ready to take the name of the Internet by Industrial and Commercial Bureau (Industrial and Commercial Bureau intranet search) if available, if not the same, you can use this name, they issued an "enterprise (name) the name of the pre-approval notice". The fee for this step is 30 yuan.

- Q: Where can I purchase 1/32 scale working RC Machinery and tractors. I see all of these videos on YouTube (will put links below) with these amazingly detailed working rc tractors and stuff. Where do these people get them from. I am noticing everyone of these videos is made in Germany. I am in the US. Please help is there a website for them.

- Rc Tractors

- Q: Electrical machinery,Is there any one to answer to my question about electrical machinery?? Thanks alot;)

- whats the question??

- Q: i can't find a website that gives you a list of some machines that are used in textiles in indusry. If you know anything at all, please help me, its driving me crazy.Thanks x x

- www.okorder / IN textile machinery there are Spinning machineries and Weaving machineries called LOOMS.and for dyeing and pritnig also there are different machineries The process of Spinning comes as Blow Room machinery. they were Platts Blow room Rieter Blow room Hergeth Blow Room Etc.

- Q: What kind of industry does the machine industry refer to?

- The main products of the machinery industry include the following agricultural machinery: tractors, seeding machines, harvesting machinery and so on. Heavy duty mining machinery: metallurgical machinery, mining machinery, lifting machinery, handling machinery, industrial and mining vehicles, cement equipment. Construction machinery: forklifts, shovel handling machinery, compaction machinery, concrete machinery, etc.. The general petrochemical machinery, oil drilling machinery, oil machinery, chemical machinery, pump, blower, valve, gas compressor, refrigeration and air conditioning machinery, paper machinery, printing machinery, plastic processing machinery, pharmaceutical machinery etc..

- Q: Is Biodiesel sufficient for old cars and older machinery that run on diesel? I know that I should not just switch to B100, but is B20 fine? Or, should I go lower, to B10, or even B5?

- it truly is a demanding one - maximum SUV's on the line as we talk gained't have any decision if switched over to completely electric powered, and the price of going 1/2 way with hybrid doesn't carry over to the completed conversion at the moment... undesirable pun, at the moment. Sorry. besides, i ought to convert to E-80 5... if it were criminal. it truly is criminal, for about 800 money for an 8 cyl, a lot less for far less cyl, to purchase a converter on your engine, and spend slightly on new gas lines, and, er... not tell absolutely everyone you install it. The EPA made it unlawful for toxins purposes, even if it pollutes a lot less - the regulation develop into written even as Propane and Methane were being considered fuels, and it develop right into a blanket regulation. Even now, people are toying with how a lot E-80 5 they could mix into their familiar gas automobile, because it truly is already 10% ethanol... The oxygen sensor many times journeys first - many cases at or below 1/2 and 1/2 mix. wintry climate and summer season mixes are different, and chilly climate would recommend demanding starts. i opt to make it sparkling that I actually have not performed this myself, yet have thoroughly researched it for both my gas injected Tahoe and sixty 9 pontiac. Please do not arrest me. better at my blog below

Send your message to us

HLS180 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords