HLS60 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A wide range of Containerized Concrete Batching Plants which have production capacity from 60m³/h to 200m³/h with one mixer. In addition to this, the capacity can be 120m³/h, 160m³/h, 180m³/h, 300m³/h and 400m³/h in Containerized Concrete Batching Plants with double mixers on the same chassis.

These Containerized Concrete Batching Plants can be used to stir all types of concrete including dry hard concrete, fluid concrete, light aggregate concrete, and others. They are mostly preferred for high capacity concrete production requirements, for special projects and for the projects which will take a long time in the same location, such as large scale building construction, water power plants, airports, docks and bridges, as well as the large and medium scale precast concrete plants, ready-mix concrete plants and pipe piles production factories.

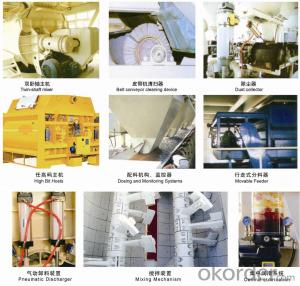

1. The host of the concrete mixing plant uses twin-shaft mixer and can produce many kinds of high-quality concrete, such as dry hard concrete and plastic concrete and others.

2. The aggregate is sent to the storage bins on the ground by the loading machine, and then is transferred to the aggregate storage buckets separately by belt conveyors and distributors;

3. Accumulative or separate metering methods can be used to measure aggregate through electronic weighing apparatus;

4. Capacity and quality of cement storage silos, and/or fly ash coal storage silos can be customized; powder materials are fed to weighing hoppers by screw conveyors for individual or cumulative measurement;

5. Water and the liquid additives are pumped to weighing hoppers for independent measurement;

6. Components and parts of famous domestic and international brands are incorporated to ensure the reliability and high production efficiency at sites:

(1) Main transmission is fitted with an Italian Bonfiglioli Brand planet gear speed reducer, which ensures high transmission efficiency, stable performance and has a strong resistance to overload.

(2) Air cylinder uses a Hymig or AIRTAC product which can be used for a long time with stable performance.

(3) The pneumatic components are from YSC or AIRTAC, which provide reliable performance with low levels of malfunction.

(4) The air compressor is a branded American Liebao product with a large air displacement capacity and steady operation.

(5) Schneider electric parts and Siemens PLC are adopted in our concrete mixing plant to ensure the reliable performance and high production efficiency.

7. Automatic production control system and feeding control system:

(1) The production control system adopts computer control and electronic scale measurement;

(2) The control system owns the functions of screen display, automatic free-fall correction, and equalize the sand containing water rate (The testing apparatus of sand containing water rate should be bought separately); manual are automatic control are both available during the mixing process;

(3) Equipped with the print system and four points monitor system to realize the central control and overall management of the whole plant, and the aggregate charging part is controlled by separated operator.

PRODUCT DETAILS:

1. Superior mixing performance

(1) Twin-shaft mixing host produce many kinds of high-quality concrete in high efficiency, such as dry hard concrete and plastic concrete and others, in high efficiency.

(2) It adopts an Italian Bonfiglioli Brand planet gear speed reducer which has the features of small volume, high efficiency and reliable performance;

(3) Its scale board and blades are made of wear-resistant casting alloys, ensuring high mixing efficiency and increasing durability;

(4) The shaft end is airproof and is completely sealed. The unique shaft-end bearing and seal design can greatly increase its durability;

(5) Overweight design provides excellent vibration absorption;

(6) Discharging door is controlled by a hydraulic pressure oil pump, equipped with three-point stop and manual open device;

(7) Centralized lubrication system adopts a 380V electric motor, which can pump the lubricate oil to the axes quickly.

2. Advanced and reliable electric control system

(1) The whole plant is controlled by computer or Siemens PLC.

(2) Manual control and automatic control systems are both available.

(3) Dynamic display panels and human-machine interface are used for the overall management and supervision of the plant functions and operations. Detailed operating information can be displayed, stored, output and printed.

(4) It has an automatic difference compensation function and can finish reserving tank production automatically.

(5) The control system, which is composed of an industrial touch screen and microcomputer, carries out the production control function to ensure reliability. When the microcomputer fails to control the normal production of the mixing plant, the industrial touchscreen can perform the function to ensure normal production, thus achieving the effect of double control by one machine.

3. Comfortable operating room

(1) Our operating room, which is totally enclosed, is fitted with an air conditioner in order to provide a working conducive environment.

4. Reliable and precise aggregate batching machine works automatically

(1) Pneumatic Batching Series: Pneumatic aggregate batching machine has a horizontal structure and adopts a cylindrical opening batching mode to batch materials. Three or four aggregate bins are available. (2) Electronic scales are used to carry out accumulative measurement or independent measurements. A programmed batching controller controls the process automatically. It has the features of high batching accuracy, short batching period and easy operation, etc.

(3) Motor Batching Series: Motorized aggregate batching machine is of a straight structure and can have two or three bins. Batching of materials is done through a belt conveyor. Electronic scales are used to carry out the function of accumulative measurement. The process is controlled automatically using a programmed batching controller. It has the characteristics of high batching accuracy, strong adaptability, easy operation and reliable performance, etc.

SPECIFICATIONS:

Model | HLS60 | |

Production capacity (m3/h) | 60 | |

Concrete mixer | Model | JS1000 |

Power (kW) | 2x18.5 | |

Output capacity (m3) | 1 | |

Aggregate size (gravel/cobble stone) (mm) | ≤60/80 | |

Batch bin | Capacity (m3) | 12 |

Belt conveyor deliverability (t/h) | 300 | |

Weighing scope and measuring accuracy | Aggregate (kg) | 2500±2% |

Cement (kg) | 500±1% | |

Fly ash (kg) | 150±1% | |

Water (kg) | 200±1% | |

Admixture (kg) | 20±1% | |

Discharging height (m) | 3.8 | |

- Q:I'm about 6'2 and really skinny. I want to gain some muscle mass, but I don't have access to very much equipment. I have a treadmill and a rowing machine. What kind of things should I eat, and what would be a good regime for me to use to gain muscle mass. I obviously don't want to loose weight so that's not an issue. How long would it be before I notice any noticeable difference? Thanks in advance.

- Hi there! Well, first things first; you say you are skinny. Gain weight first. You need fat to build muscle. Between 5 and 10 kilos should do the trick. Second; when you have gained weight, start eating lots of proteine, they are the muscle's building blocks. You'll find it in pork, chicken, turkey, shrimps etc. Third; with a tread mill and a rowing machine, you'll have more than enough:) Start wormin up, some people need longer than others, but you should really fil hot and start sweating. So then you could work on your rowing machine, they almost take every muscle in your body after what I have hard. But I also recomend pushups, squats, and situps(also do situps for your back! Very important!). Don't do crunches, they suck! Do one of these, or both, in stead; lie on your back, lift your feet in a 45 degree angle from the floor, and write the numbers from 1 to 10 in the air, and down again. The other one is just like it, but here you rais your feet all the way towards the roof, and use your abs to lift your bum of the floor as high as you can. For your triceps(muscle just beneth your elbow), turn your back to a bed, chair or something, but your hands on the edge, and then sit down on the floor. Use your arms to pull yourself up and down. This should be more than enough to get you started. Remember to dring lots of water and monitor your progress. It will help your motivation. Search the web for more exercises you can do without equipment. How long it will take depends on your genes and how hard you work, so it's difficult to say. Anyway, good luck!

- Q:For example: Humans vs. Artificial humans (robots)

- Heres a few I could think of. Salmon vs Hydroelectric dam Barnacles vs Boat Weathering and Erosion vs Road Rust vs Car

- Q:Do you know the theodolite? How about Yu Rong Machinery Theodolite-DE laser series electronic theodolite?

- Good visibility of the laser line; Large LCD display; Independent lilf sensor can auto-corrected; More convenience when the instruments is combined with the Diagonal Eyepiece

- Q:a.mRNAb.tRNAc.translation factorsd.ribosomese tein polymerase

- (e): Protein Polymerase You don't need polymerase in translation. mRNA, tRNA, ribosome, translation factors are all used in the translation machinery.

- Q:What are it's advantages and disadvantages in both commercial farming and subsistence farming?

- Good question Advantages of Commercial Farming Can generate cash, the products are therefore intended to be marketed for profit. An extra profit is needed to fund the next cropping activities. A positive impact on an economy, unemployment decreases more people and resources are fully utilize and as a result government generates more revenue through taxes which makes an economy of a country more powerful. Disadvantages of Commercial Farming is that only certain crops would be produce as it has more money value. Peoples' would not get a variety to choose. Advantages of Subsistence Farming The people who worked there can get the food and it is a quite cheap as compare to Commercial Farming where excess of money is required to operate the farm whereas in subsistence farming you just have to buy a little piece of land and little money to be spend on the crops. Disadvantages are there is no proper source of income in this farming system. Difficult to buy seeds for new crops due to a cash-flow problem. A farmer has to work hard to yields the crops. Hope this helps and I think you are a student, if is it so then I am sure with this answer you would get 100% :)

- Q:how to Degrease machinery in the clothes?

- Rub okorder /

- Q:i want to sell an unused candle maker

- The questions need to ask yourself are: - Is the weight of the product and corresponding freight cost going to be prohibitive for anyone bidding internationally or far from my local area? - Is my product too specialised for OKorder? - do I need a large national/international group of prospective buyers to ensure a sale? You may in fact be better off finding a more specialised sales platform. Good luck.

- Q:Hi! Thanks for reading this. Let's get to my questions...Okay so I've noticed that I can barely do 20 consecutive push-ups without my arms going weak. After this happens, it's almost impossible to do even one more. Is something wrong with me, or am I just a little out of shape? (Not fat)Also, I'd really appreciate if you can list some upper-body workouts one could do at home that require no extra equipment (ex: push-ups, sit-ups) Thanks!

- in case you decide directly to paintings somewhat on abs, do sprints quite than long runs. the excellent ab workout without kit is the bicycle the place you lay flat on the floor, and you convey your knee a pair of million/2 way on your chest and touch it with your opposite elbow. the only meals advice i delivers you is to consume 6 small nutrients, and get protein.

- Q:improvements in machinery,technology and farming techniques?

- No other segment of our economy has made the advances in productivity that agriculture has. The problem arises from the cost of highly sophisticated equipment needed to free our work force for other endevors. In the early 1900's about half of our people actually lived on the farm. today that is less than 2%. It can cost $200,000 to buy a grain combine and other equipment is priced comparably, yet no one will even write a farm loan in our county unless you own the land free and clear and are willing to accept less than a 1% return on that investment. If farmer's did not love their life style and independance we would all starve because they just wouldn't do this as pure business men. The result of this has been more corporate large scale farms even if they are operated by families and a lessening of attention to animal welfare, purity of produce, and concern for the quality of the output. Machinery is highly sophisticated. tractors guide themselves through the fields, fertilizer is applied using global positioning systems, and seed placement is very precision, all resulting to a reduction of labor and increased costs of production for prices that won't pay the bills.

- Q:Location: USA - I get 120v on all 3 legs of 3 phase system but check 208v between any 2 legs. Can I step it up to 240v without a transformer? My machinery specifies 240v

- Most houses are supplied with only two of the three phases available in the USA. The circuit breaker box divides the two phases into two sets of 110 volts (each phase to ground) and also has circuit breakers for 220 volts (across the two phases) for clothes dryers and electric stoves, etc. Most factories are supplied with all three phases and certain motors can be connected (by licensed electricians) across all three phases to obtain 440 volts using a motor controller. Local codes and insurance requirements are two good reasons to hire a licensed electrician to safely connect the motor. A transformer may be required to obtain 220 volts and three phase current. Also check the name plate data to determine the required frequency (60 Hz) in the USA.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HLS60 Environmentally Friendly Ready Mix Concrete Batch Plant

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords