Vapor Barrier Membrane with PE Film and Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vapor Barrier Membrane with PE Film and Non-Woven Fabric

Company Information:

We are located in National Development Zone in Nantong, with 22000 square meters area, including 7000 square meters dust free workshop.

We have equipped the most advanced pp non-woven production line and composite production lines including extrusion lamination production, hot melt lamination production line, calendar bonded production line with the technology from Italy and Germany, printing production line, cutting production line. We specialize in producing waterproof and breathable materials and heat insulation materials, pp non-woven fabric, disposable medical products, packaging materials and so on.

Products Information:

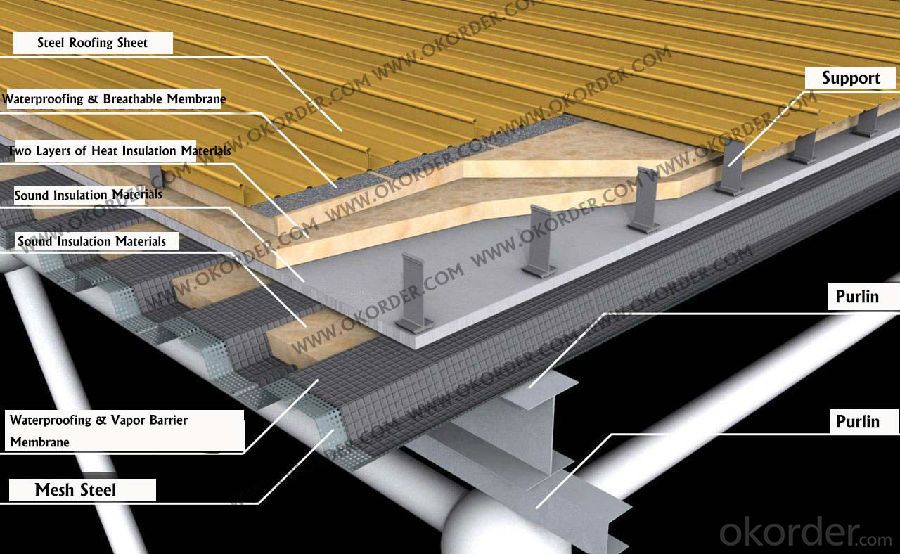

Vapor Barrier membrane is a roof membrane with three-layers, which is specially designed for application on ventilated pitched roofing, can be used under bituminous membrane as a extra protection for the attic insulation. It includes PET/PP non-woven fabric layer, PE/PP woven layer and aluminum foil layer. The three-layers structure ensure extreme resistance to tearing. Furthermore, the special stabilization additives ensure 3-month resistance to UV radiation.

Specifications:

Chemical Composition | PP & PE, Aluminum Foil, Woven Fabric |

Roll Size | 1.5meter*50meter |

Density: | 60gsm~130gsm |

Tensile Strength | MD:150N/50mm; CMD:115N/50mm |

Waterproofing Rate | W1 |

Vapor Resistant Rate | 6.9g/m2 ▪ 24h |

Aging rate under hot circumstance (90℃*168h) | MD:90%; CMD:100% |

Typical Application:

Container Loading:

FAQ:

1. Where is your factory located in?

Our factory is located in Jiangsu province, close to Shanghai.

2. Have you ever been export?

Yes, our product has been exported to many countries.

3. Can we get samples?

Yes, we are free for samples, what you need to assume is freight charge.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 4, select the appropriate waterproof material, generally designed for waterproofing membrane.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Five, scraping gum The excess residue of the material to be scratched, scraping plastic tool angle consistent, at one go, scraping gum immediately after the completion of tearing tape or grain pattern paper. Remove the excess glass compound, if stains, can be removed with a damp cloth. Six, finished product protection Do not touch within 24 hours, do not press within 48 hours.

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Second, the chisel in addition to the wall structure to the wall structure for waterproof construction, you can use the material coating, membrane and infiltration of crystallization, the quality is different.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- Due to uneven settlement of buildings and other factors, resulting in deformation of the building structure cracking, leakage phenomenon, for the repair of this situation, you can use a new foreign plugging construction technology - high pressure grouting waterproof repair technology.

- Q: Developers have done waterproof, decoration house also have to do it

- Secondly, before the waterproof layer may be done in the house decoration, paving tiles or other equipment when the installation was destroyed, so that the waterproof layer is no longer a whole,

- Q: Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

- Q: How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- Bathroom waterproof acceptance: material acceptance: 1: materials need to meet the national standards, the need for a product certificate of competency. Construction acceptance: 1: grass-roots surface should be flat, no hollowing, from the sand, cracking and other defects. Base water content should meet the construction requirements of waterproof materials.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar and cement mortar difference: Cement mortar is the synthesis of three main materials, cement, sand and water, and mixed mortar is the synthesis of four major materials, cement, sand, lime and water.

Send your message to us

Vapor Barrier Membrane with PE Film and Non-Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords