Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Column Formwork Outrigger For Scaffolding With New Design

Plastic Formwork Concrete Formwork Circular Column Used Scaffolding Props New Design

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

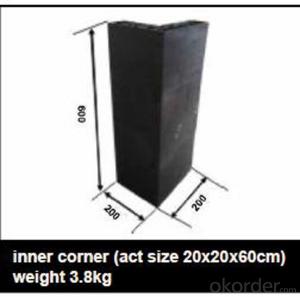

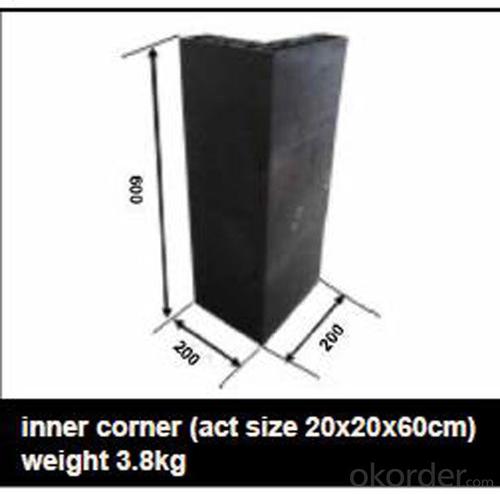

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels..

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

5.Environment friendly

The system needs no cut and nail due to the variety size. Also it needs nearly no wood. The material can be recycled after broken, so it will not pollute the environment.

6.Consequent

Concrete does not stick to plastic formwork, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which build by modular formwork is smooth and without rework.

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Advantage

* Good loading capacity

* Easy to assemble and dismantle

* Stable and durable thanks to its structual design & automatic welding quality

* Customized solution helps you work safe, save cost and convenient

* Excellent quality for formwork & scaffolding with wide choices

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

FAQ Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

Why Us?

We are one of the Top 500 in the world, largest construction materials supplier in China. Also we are a state-owned company and respond to every customer with large and also small orders.

We own professional manufacturers with powerful producing capacity.

Extensive and comprehensive quality control system

Excellent products with competitive prices.

Efficient services in pre and after sale.

Full energy with affluent experience team.

- Q: Are there any specific code or regulatory requirements for using steel frame formwork?

- Yes, there are specific code and regulatory requirements for using steel frame formwork in construction projects. These requirements may vary depending on the country and region, as different jurisdictions have their own building codes and regulations. In general, steel frame formwork systems must comply with structural design standards and codes that ensure the safety and integrity of the structures being built. These codes typically cover aspects such as load-bearing capacities, stability, and durability of the formwork system. For instance, in the United States, the American Concrete Institute (ACI) provides guidelines and standards for formwork design and construction. ACI 347R-14, "Guide to Formwork for Concrete," offers recommendations for steel formwork systems, including criteria for strength, stability, and dimensional tolerances. Similarly, the European Union has its own set of regulations and standards for formwork systems. The European Standard EN 12812:2008, "Falsework - Performance requirements and general design," specifies the requirements for steel formwork, including aspects such as load-bearing capacity, safety factors, and material properties. It is essential for contractors and designers to comply with these code and regulatory requirements when using steel frame formwork in construction projects to ensure the safety of workers and the structural integrity of the final building. Failure to adhere to these requirements may lead to accidents, structural failures, or non-compliance with building regulations, resulting in legal consequences and potential liability. Therefore, it is crucial to consult the relevant building codes and regulations in the specific jurisdiction where the construction is taking place to ensure compliance with the specific requirements for steel frame formwork.

- Q: What are the different types of form ties used in conjunction with steel frame formwork?

- In conjunction with steel frame formwork, different types of form ties are commonly utilized. These form ties play a crucial role in securing the formwork panels together and guaranteeing the stability and strength of the overall system. 1. Loop Ties: Loop ties are extensively employed as form ties. They consist of a steel wire loop that is threaded through the formwork panels and then twisted or bent to fasten the panels together. Loop ties possess flexibility and can adapt to various formwork configurations. 2. Flat Ties: Another frequently employed form tie is the flat tie. Made of steel, these ties have a flat shape, typically with holes or notches along their length. Flat ties are inserted through the formwork panels and secured using a wedge or pin. They establish a robust connection between the panels, contributing to the formwork's structural integrity. 3. Snap Ties: Designed for swift and effortless installation, snap ties are a form of form tie. They comprise a metal rod with a button-like end that snaps into a plastic cone or washer. Snap ties find common use in scenarios requiring rapid assembly and disassembly of the formwork. 4. Coil Ties: Coil ties are constructed from coiled steel wire and serve as form ties. They are commonly employed when high load capacity is necessary. Coil ties can be easily inserted through the formwork panels and secured using a coil nut or rod. They offer a dependable and durable connection between the panels. 5. Cone Ties: Also known as taper ties, cone ties are form ties featuring a cone-shaped end. The cone end is inserted through the formwork panels and then secured using a wedge or pin. Cone ties are frequently used in applications where a smooth and flush finish is desired, as the cone end can be easily removed after the concrete has cured. In conclusion, the selection of a form tie depends on the specific requirements of the project, taking into account factors like load capacity, ease of installation, and desired finish. It is imperative to choose the appropriate form tie to ensure the stability and strength of the steel frame formwork system.

- Q: What are the key considerations for selecting the appropriate steel frame formwork supplier for international projects?

- When selecting an appropriate steel frame formwork supplier for international projects, there are several key considerations to keep in mind. Firstly, it is crucial to assess the supplier's experience and reputation in the industry. Look for a supplier with a proven track record of successfully delivering steel frame formwork for international projects. This can be done by reviewing their portfolio, client testimonials, and industry certifications. Secondly, consider the supplier's ability to provide customized solutions. International projects often have unique requirements and specifications, so it is important to work with a supplier who can tailor their steel frame formwork to meet these specific needs. Additionally, logistics and supply chain management play a significant role in selecting the appropriate supplier. Look for a supplier with a robust global distribution network, efficient shipping processes, and the ability to handle any necessary customs or import/export procedures. Furthermore, the quality and durability of the steel frame formwork are essential factors to consider. Ensure that the supplier uses high-quality materials and has stringent quality control measures in place. This will ensure that the formwork will withstand the demands of international projects and provide long-lasting performance. Lastly, consider the supplier's customer service and support capabilities. International projects can be complex and may require ongoing assistance and technical guidance. Choose a supplier who is responsive, offers reliable after-sales service, and can provide timely support when needed. By considering these key factors, you can select an appropriate steel frame formwork supplier for international projects that will meet your project's requirements, deliver high-quality products, and provide the necessary support throughout the project duration.

- Q: What are the common maintenance practices for steel frame formwork systems?

- To maintain steel frame formwork systems, it is important to regularly clean and inspect them, lubricate their moving parts, and repair or replace any damaged components. Cleaning is a crucial maintenance practice that involves removing any debris, concrete residue, or other materials that may have accumulated on the frames and panels. By regularly cleaning the formwork system, you can prevent corrosion and ensure its overall good condition. Inspection is another essential maintenance practice. It involves thoroughly examining the formwork system for any signs of damage or wear. This includes inspecting the frame, panels, connecting hardware, and other components for cracks, dents, or loose parts. It is important to conduct inspections before and after each use, as well as periodically during long projects. If any issues are detected during the inspection, they should be promptly addressed to prevent further damage. Lubrication is necessary for the smooth operation of the moving parts in a steel frame formwork system. This includes applying lubrication to hinges, locks, and other mechanisms to ensure their proper functioning. By lubricating these parts, you can reduce friction and wear, which in turn can extend the lifespan of the formwork system and enhance its performance. Repairing or replacing damaged components is crucial for maintaining the integrity of the steel frame formwork system. Any components that are cracked, bent, or otherwise damaged should be repaired or replaced as soon as possible. This may involve replacing worn-out panels, repairing damaged frames, or replacing faulty hardware. Regular inspections and prompt repair or replacement of damaged components can prevent accidents and help ensure that the formwork system remains safe and reliable. To summarize, common maintenance practices for steel frame formwork systems include regular cleaning and inspection, lubrication of moving parts, and repair or replacement of damaged components. By following these practices, you can ensure the longevity and proper functioning of the formwork system, promoting safety and efficiency on construction sites.

- Q: How does steel frame formwork handle the placement of soundproofing and acoustical materials within the concrete structure?

- The incorporation of soundproofing and acoustical materials into a concrete structure can be easily achieved using steel frame formwork. This method provides a stable and secure framework, allowing for precise placement of these materials during the pouring of concrete. Steel frame formwork can be customized to meet the specific requirements of soundproofing and acoustical materials. It can be designed with openings or recesses to accommodate the placement of these materials at desired locations, ensuring optimal sound insulation throughout the structure. Furthermore, the installation and removal of formwork panels is made easy with steel frame formwork. This simplifies the process of installing soundproofing and acoustical materials, as the panels can be adjusted or modified to fit the specific dimensions and shapes required. In addition to its versatility, steel frame formwork provides excellent structural integrity and stability. This ensures that the soundproofing and acoustical materials remain securely in place during the pouring and curing of concrete, preventing any displacement or damage that could compromise their effectiveness in reducing sound transmission. To summarize, steel frame formwork is a highly suitable method for incorporating soundproofing and acoustical materials into a concrete structure. Its precision, stability, and adaptability make it an ideal choice for achieving optimal sound insulation in the finished building.

- Q: How does steel frame formwork prevent the formation of concrete spalling or surface chipping?

- Steel frame formwork prevents the formation of concrete spalling or surface chipping by providing strong and rigid support to the concrete during the pouring and curing process. The steel frame holds the concrete in place, ensuring that it does not shift or crack, thus reducing the risk of spalling or chipping. Additionally, the smooth surface of the steel frame helps create a uniform and even finish for the concrete, further minimizing the chances of any surface defects.

- Q: Can steel frame formwork be used in projects with limited project duration or tight schedules?

- Yes, steel frame formwork can be used in projects with limited project duration or tight schedules. Steel frame formwork is known for its durability, strength, and quick assembly and disassembly process. It allows for faster construction and turnaround times, making it suitable for projects that require efficiency and speed.

- Q: Is steel frame formwork suitable for the construction of bridges?

- Yes, steel frame formwork is suitable for the construction of bridges. Steel offers high strength and durability, making it capable of withstanding the heavy loads and forces exerted by bridge structures. Steel frame formwork also allows for easy customization and adjustment, making it an ideal choice for complex bridge designs. Additionally, steel formwork can be reused multiple times, making it a cost-effective option for bridge construction projects.

- Q: How does steel frame formwork handle the placement of fire-rated barriers and partitions within the concrete structure?

- Steel frame formwork provides a robust and efficient solution for the placement of fire-rated barriers and partitions within a concrete structure. With its strong and durable nature, steel frame formwork ensures the accurate positioning and alignment of these fire-rated elements. The rigid framework allows for precise installation, ensuring that the barriers and partitions are securely embedded within the concrete structure, providing reliable fire protection. Additionally, steel frame formwork allows for easy adjustment and modification when necessary, making it a versatile choice for incorporating fire-rated barriers and partitions into the concrete structure.

- Q: Can steel frame formwork be used for the construction of religious buildings?

- Certainly, religious buildings can indeed be constructed using steel frame formwork. This construction technique is incredibly versatile and long-lasting, allowing for the creation of intricate and complex designs. Religious buildings often boast unique and elaborate architecture, and steel frame formwork is well-equipped to meet these specific requirements. Furthermore, steel frame formwork offers exceptional strength and stability, which is crucial for the construction of large and iconic religious structures. Not only that, but steel is also an environmentally friendly and sustainable material, aligning perfectly with the sustainability and environmental consciousness often prioritized in religious buildings. In conclusion, steel frame formwork is a feasible choice for constructing religious buildings, providing the necessary structural integrity and aesthetic appeal necessary for such endeavors.

Send your message to us

Used Scaffolding Boards For Sale Formwork Steel Scaffolding Pipe Weights High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords