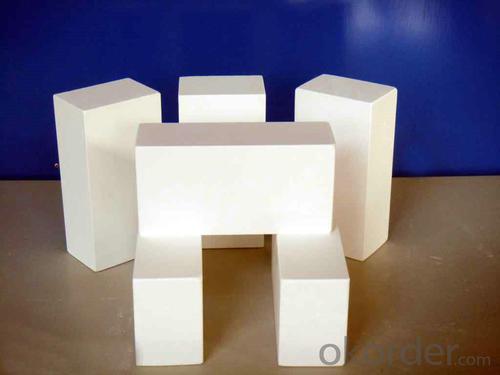

Insulating Fire Brick - Unshaped Refractory Fire Clay Bricks for Furnace Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of kilns?

- Yes, insulating fire bricks can be used in the construction of kilns. Their high insulating properties help to retain heat and improve energy efficiency in the kiln, making them a popular choice for lining the walls and floor of kilns.

- Q: What is the price of fireproof insulation material?

- A preliminary understanding of price through online preliminary understanding, now generally the size of the opening of the cable insulation material manufacturers are on business, early online now have a preliminary understanding, manufacturers investigation after considering cooperation.

- Q: Can insulating fire bricks be custom-made?

- Yes, insulating fire bricks can be custom-made. Insulating fire bricks are typically made from lightweight materials such as vermiculite, perlite, or refractory fibers, which can be easily molded into various shapes and sizes. This flexibility allows manufacturers to create custom-made insulating fire bricks to meet specific requirements and applications. Customization options may include variations in dimensions, thermal conductivity, compressive strength, and density. By tailoring the composition and design of insulating fire bricks, they can be optimized for specific temperature ranges, insulation requirements, and environmental conditions. Therefore, customers can work with manufacturers to develop custom solutions that best suit their unique needs.

- Q: Can insulating fire bricks be used in cement plants?

- Certainly, cement plants can utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are widely employed in thermal insulation-demanding industries. Within cement plants, they can find diverse applications, including kiln lining, furnace lining, and other equipment operating at high temperatures. These bricks effectively decrease heat dissipation, enhance energy efficiency, and maintain stable and regulated temperatures during cement production. Furthermore, insulating fire bricks possess a lightweight nature and exhibit low thermal conductivity, rendering them an optimal selection for insulation purposes within cement plants.

- Q: Do insulating fire bricks have good mechanical strength?

- Insulating fire bricks generally have moderate mechanical strength compared to regular fire bricks. While their main purpose is to provide excellent thermal insulation, they are still able to withstand some amount of mechanical stress. However, it is important to note that their mechanical strength may not be as high as other types of fire bricks, which are specifically designed to withstand heavier loads and abrasion. Therefore, if the application requires both high insulation and superior mechanical strength, it might be necessary to consider using a combination of insulating fire bricks and regular fire bricks to achieve the desired outcome.

- Q: Can insulating fire bricks be used in the construction of industrial dryers?

- Yes, insulating fire bricks can be used in the construction of industrial dryers. Insulating fire bricks are specifically designed to have low thermal conductivity, which means they are able to retain heat and prevent heat loss. This makes them an excellent choice for applications that require high temperatures, such as industrial dryers. Insulating fire bricks are made from lightweight materials such as clay, silica, and alumina, and are capable of withstanding temperatures of up to 3000°F (1650°C). They have excellent insulation properties, which help to reduce energy consumption and improve the overall efficiency of the industrial dryer. Additionally, insulating fire bricks are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly important in industrial dryer applications, where temperatures can fluctuate quickly. Overall, insulating fire bricks are a suitable choice for the construction of industrial dryers due to their low thermal conductivity, high temperature resistance, and ability to withstand thermal shock.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Insulating fire bricks exhibit exceptional resistance to weathering and aging. These bricks are specifically engineered to endure extreme temperatures and harsh environmental conditions. They are composed of top-notch refractory materials, including alumina, silica, and other additives, which confer exceptional thermal insulation properties and strong resistance to corrosion and erosion. The manufacturing process of insulating fire bricks entails meticulous selection of raw materials and precise control of firing temperatures, resulting in a dense and homogeneous structure. This structure effectively prevents moisture and other weathering agents from infiltrating, thus ensuring extended durability and resistance to aging. Moreover, insulating fire bricks are also highly resistant to thermal shock, enabling them to withstand rapid temperature fluctuations without fracturing or disintegrating. This characteristic bolsters their ability to withstand adverse weather conditions. All in all, insulating fire bricks have demonstrated remarkable dependability in diverse applications that involve exposure to weathering elements. They find widespread usage in industries such as steel, ceramic, glass, and cement manufacturing, as well as in high-temperature applications like kilns, furnaces, and chimneys.

- Q: Can insulating fire bricks be used in chimneys or flue systems?

- Yes, insulating fire bricks can be used in chimneys or flue systems. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation. They are commonly used in applications where heat needs to be retained or reflected, such as in chimneys or flue systems. These bricks are capable of withstanding temperatures up to 3000°F (1650°C), making them ideal for use in environments with extreme heat. Additionally, their insulating properties help to minimize heat loss, improve energy efficiency, and prevent damage to surrounding structures. However, it is important to note that insulating fire bricks should be installed according to the manufacturer's guidelines and local building codes to ensure safe and proper usage.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Insulating fire bricks are capable of being utilized in the construction of lime production linings. These bricks are specifically designed to possess low thermal conductivity, making them exceptionally beneficial for applications that necessitate heat insulation. In the process of calcination that takes place during lime production, high temperatures are essential. By incorporating insulating fire bricks into the construction of lime production linings, heat loss can be minimized, thus enhancing energy efficiency. Furthermore, these bricks are lightweight and easy to manipulate, rendering them suitable for lining various components of lime kilns and other equipment employed in the lime production process. In summary, the utilization of insulating fire bricks in lime production linings has the potential to optimize the production process and enhance the overall performance of lime production facilities.

- Q: Do insulating fire bricks require any special installation techniques?

- Yes, insulating fire bricks require special installation techniques. These bricks are typically lightweight and have low thermal conductivity, making them highly effective in insulating applications. To ensure proper installation, it is important to follow the manufacturer's guidelines and use appropriate tools, such as refractory mortar or adhesive, to securely bond the bricks together. Additionally, proper curing and drying procedures should be followed to avoid any potential cracking or damage during the installation process.

Send your message to us

Insulating Fire Brick - Unshaped Refractory Fire Clay Bricks for Furnace Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords