Unequal Angle Steel Hot Sale High Tensile China Prime Small GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

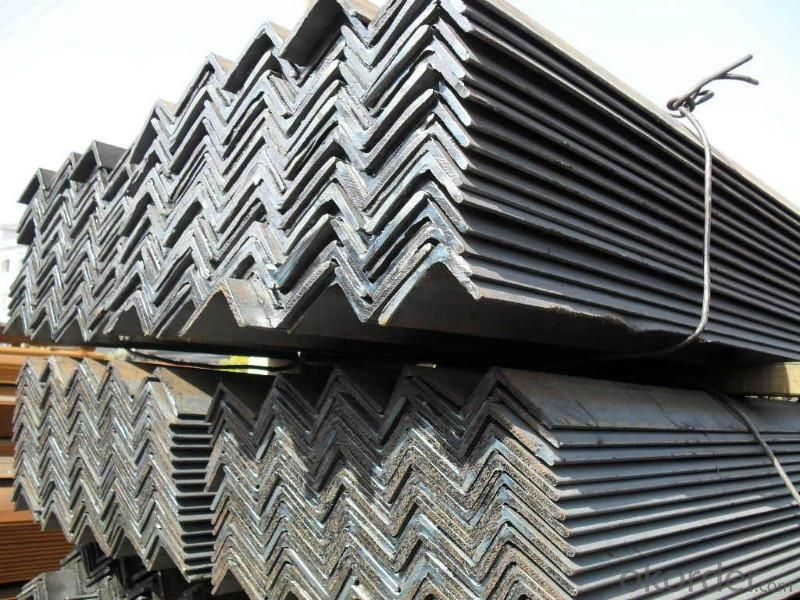

Packaging & Delivery

| Packaging Detail: | angle steel packed in bundle or as customer's requirements. |

| Delivery Detail: | 10-30 days after customer placed the angle steel order |

Specifications

gb standard unequal angle steel

1.high dimensional accuracy

2.beauty appearance

3.save 28%-30% raw materials

4.BV

Details of Angle steel

| Name | Angle steel |

| Standard | AISI, ASTM, BS,DIN,GB,JIS |

| Grade | A36, SS400, Q235, Q345, S235,S275 |

| Dimensions | 25*3-200*20 |

| Length | 6-12m |

| Technique | Hot rolled steel angle bar |

| Tolerance | As the standard or as your requirement |

| Surface treatment | Galvanized, paint |

| Application | Metal structure, bridge, machiner, shipbuilding industry |

| Certificated | BV |

| Packing details | standard export packing or as your requirement |

| MOQ | 5 tons |

| Delivery | Within 25 days after deposit |

| Payment | T/T or L/C |

Advantage of Angle steel

1.Convenient in construction and save much time and labor

2.High mechanical strength

3.Low price, high quality

Size of Angle steel

| Equal angle(A*T) | |||||

Size (mm) | Theoretical weight (kg/m) | Size (mm) | Theoretical weight (kg/m) | Size (mm) | Theoretical weight (kg/m) |

| 25*3 | 1.124 | 75*7 | 7.976 | 110*14 | 22.809 |

| 25*4 | 1.459 | 75*8 | 9.03 | 125*8 | 15.504 |

| 30*3 | 1.373 | 75*10 | 11.089 | 125*10 | 19.133 |

| 30*4 | 1.786 | 80*6 | 7.376 | 125*12 | 22.696 |

| 40*3 | 1.852 | 80*7 | 8.525 | 125*14 | 26.193 |

| 40*4 | 2.422 | 80*8 | 9.658 | 140*10 | 21.488 |

| 40*5 | 2.976 | 80*10 | 11.874 | 140*12 | 25.522 |

| 50*4 | 3.059 | 90*6 | 8.35 | 140*14 | 29.49 |

| 50*5 | 3.77 | 90*7 | 9.658 | 140*16 | 35.393 |

| 50*6 | 4.465 | 90*8 | 10.946 | 160*10 | 24.729 |

| 60*5 | 4.52 | 90*10 | 13.476 | 160*12 | 29.391 |

| 60*6 | 5.42 | 90*12 | 15.94 | 160*14 | 33.987 |

| 63*5 | 4.822 | 100*6 | 9.366 | 160*16 | 38.518 |

| 63*6 | 5.721 | 100*7 | 10.83 | 180*12 | 33.159 |

| 63*8 | 7.469 | 100*8 | 12.276 | 180*14 | 38.518 |

| 63*10 | 9.151 | 100*10 | 15.12 | 180*16 | 43.542 |

| 70*5 | 5.397 | 100*12 | 20.611 | 180*18 | 48.634 |

| 70*6 | 6.406 | 100*16 | 23.257 | 200*14 | 42.894 |

| 70*7 | 7.398 | 110*7 | 11.928 | 200*16 | 48.68 |

| 70*8 | 8.373 | 110*8 | 13.532 | 200*18 | 54.401 |

| 75*5 | 5.818 | 110*10 | 16.69 | 200*20 | 60.056 |

| 75*6 | 6.905 | 110*12 | 19.782 | ||

gb standard unequal angle steel

- Q: How do steel angles contribute to the overall stiffness of a structure?

- The overall stiffness of a structure is enhanced by steel angles in various ways. Firstly, they offer additional support and rigidity to the framework. Their L-shape allows them to reinforce the corners and edges of different components like beams, columns, and trusses, preventing buckling, twisting, or bending under heavy loads or external forces. Furthermore, steel angles can be strategically positioned in crucial areas of the structure to efficiently resist and distribute loads. By incorporating steel angles as bracing elements, the structure's overall stiffness improves, reducing the risk of excessive deflection or deformation. This is especially vital for structures exposed to dynamic loads, such as wind or seismic forces, as the angles effectively resist and dissipate these forces throughout the structure. Moreover, steel angles can be interconnected to create a network of diagonal bracing, greatly enhancing the structure's stiffness and stability. This bracing system allows the angles to transfer loads from one component to another, effectively minimizing the possibility of failure or collapse. Additionally, using steel angles in this manner reduces the required material and weight, making the structure more cost-effective and efficient. To summarize, steel angles play a pivotal role in contributing to a structure's overall stiffness by providing reinforcement, supporting key components, and distributing loads. Their strength and versatility make them an essential element in designing and constructing various types of structures, guaranteeing stability, durability, and safety.

- Q: How do you design connections for steel angles?

- Designing connections for steel angles involves several key steps. Firstly, determine the loads that the connection will need to withstand, such as vertical and horizontal forces, moments, and shear forces. This will help determine the required strength and size of the connection. Next, select an appropriate connection type based on the specific application and load requirements. Common connection types for steel angles include bolted connections, welded connections, and a combination of both. In the case of bolted connections, design the connection by calculating the required number and size of bolts based on the applied loads. Consider factors such as bolt spacing and edge distances to ensure proper load transfer and prevent failure. For welded connections, ensure that the angles are properly prepared, aligned, and welded in accordance with the applicable codes and standards. Proper welding techniques and procedures should be followed to ensure the integrity and strength of the connection. During the design process, it is important to consider factors such as material properties, joint configurations, and the potential for corrosion or fatigue. Additionally, it is essential to consult relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, to ensure compliance and safety. Overall, designing connections for steel angles requires careful consideration of loads, connection types, and construction techniques to ensure a secure and reliable connection that meets the structural requirements.

- Q: What is the maximum axial load for a steel angle?

- The maximum axial load for a steel angle depends on various factors such as the dimensions and grade of the steel angle, as well as the specific application and design considerations. Therefore, it is difficult to provide a specific maximum axial load without knowing these details. Consulting engineering specifications or a structural engineer would be necessary to determine the maximum axial load for a specific steel angle.

- Q: How do steel angles contribute to the overall lateral stability of a structure?

- Steel angles contribute to the overall lateral stability of a structure in several ways. Firstly, they can be used as bracing members to resist lateral forces such as wind or seismic loads. By connecting the angles to the main structural elements of the building, they help to distribute these forces and prevent the structure from collapsing or deforming under the applied load. Additionally, steel angles can be utilized as stiffeners to enhance the stiffness and rigidity of key structural components. By adding angles to beams, columns, or other elements, their resistance to bending or buckling is increased, thereby improving the overall lateral stability of the structure. Moreover, steel angles can act as shear connectors between different structural elements. By welding or bolting angles to beams, for example, they create a connection that enables the transfer of shear forces between the components. This is crucial for ensuring that the structure remains stable and can withstand lateral loads without significant deformation or failure. Furthermore, steel angles can be employed as diagonal members in truss systems. By forming diagonal bracing, they help to distribute the applied loads more evenly across the structure, preventing excessive lateral displacements and maintaining the overall stability of the building. Overall, steel angles play a vital role in enhancing the lateral stability of a structure. Their use as bracing members, stiffeners, shear connectors, and diagonal members all contribute to distributing and resisting lateral forces, ensuring that the structure remains stable and capable of withstanding external loads.

- Q: Can steel angles be used in modular construction?

- Yes, steel angles can indeed be used in modular construction. They are commonly used as structural elements to provide stability and support in modular buildings.

- Q: Are steel angles suitable for scaffolding?

- Yes, steel angles are suitable for scaffolding. They are commonly used in scaffolding systems due to their strength, durability, and ability to provide stable support for workers and materials. Steel angles offer excellent load-bearing capacity and can withstand heavy loads, making them a reliable choice for scaffolding structures.

- Q: What are steel angles?

- Steel angles are a type of steel structural shape that is commonly used in construction and engineering projects. They are L-shaped beams with two legs of equal or unequal length, forming a 90-degree angle. Steel angles are typically made from hot-rolled steel and can be found in various sizes and thicknesses. These angles are versatile and have a wide range of applications. They are commonly used as framing elements in buildings and bridges, providing support and stability. Steel angles can also be used as reinforcement in concrete structures or as brackets and supports for various equipment and machinery. One of the key advantages of steel angles is their strength and durability. They are designed to withstand heavy loads and provide structural integrity. Additionally, steel angles are resistant to corrosion, making them suitable for outdoor applications and environments with high moisture or chemical exposure. Steel angles are available in different grades, with each grade having specific mechanical properties and characteristics. This allows engineers and designers to choose the appropriate angle based on the requirements of the project. In conclusion, steel angles are essential components in construction and engineering. They provide strength, stability, and versatility in various applications. Whether it is for structural support or reinforcement, steel angles play a crucial role in ensuring the integrity and safety of a wide range of structures.

- Q: How are steel angles protected against fire damage?

- Steel angles can be protected against fire damage through the application of fire-resistant coatings or by encasing them in fireproof materials such as concrete or gypsum board. Additionally, fireproofing sprays or intumescent paints can also be used to provide a layer of insulation that helps to slow down the spread of fire and protect the steel angles from excessive heat.

- Q: What are the considerations for selecting the appropriate steel angle length?

- When selecting the appropriate steel angle length, there are several considerations to keep in mind. Firstly, the intended application and usage of the steel angle should be considered. This includes factors such as the load-bearing capacity required, the structural design of the project, and any specific engineering or architectural requirements. Secondly, the dimensions and measurements of the project should be taken into account. This involves considering the overall size and shape of the structure, as well as the specific location and orientation where the steel angle will be installed. Additionally, the availability and cost of different steel angle lengths should be considered. It is important to assess the cost-effectiveness and availability of different lengths to ensure that the chosen length aligns with the project budget and timeframe. Lastly, it is crucial to consult industry standards and regulations when selecting the appropriate steel angle length. Adhering to specific guidelines and codes ensures the safety and compliance of the structure, and helps to avoid any potential issues or risks in the future. By considering these factors, one can make an informed decision when selecting the appropriate steel angle length for their specific project.

- Q: How do you calculate the weight-bearing capacity of a steel angle?

- To calculate the weight-bearing capacity of a steel angle, you need to consider its dimensions, material properties, and loading conditions. The weight-bearing capacity can be calculated using engineering formulas and techniques such as the Euler formula or the AISC Manual. These calculations take into account factors like the cross-sectional area, moment of inertia, and the applied loads to determine the maximum load the steel angle can support without failure.

Send your message to us

Unequal Angle Steel Hot Sale High Tensile China Prime Small GB Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 27 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords