Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

OKorder is offeringUnequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

OKorder's Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled are durable, strong, and resist corrosion.

Main Product Features of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

Hot Rolled Steel Unequal Angles

1. Shape:Unequal

2. Standard:ASTM,BS,DIN,GB,JIS

3.Grade:Q195,Q235,Q345,SS400,A36,ST37

May we help you to optimize your products sourcing? | |

1. Strategic location: Our factory is located in the famous steel town of Shengfang. | |

2. Industrial product expertise | |

3. Product reliability, competitive price, and on-time delivery | |

4. Unparalleled service and reliability | |

5. Business philosophy: Credit First, Be Honesty, Mutual Benefit and Customer Supremacy. | |

Detail information: | |

Type | Equal & Unequal |

Thickness Tolerance | +/- 8% |

Packing | export standard packing(bundles, seaworthy package, shipped in container) |

Delivery Port | Tianjin, China |

Lead Time | within 30days after received the original L/C or deposit |

MOQ | 10 Tons per size |

Certificate | SGS Certificate if needed; the cost of inspection for buyer. |

Usage | Construction, communications steel tower, civil or agricultural machine making |

Production Capacity | 5,000MT per month |

Main Market | Europe, America, Africa, Southeast |

Welcome every old and new clients to come to negotiate and telecommunicate with us | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

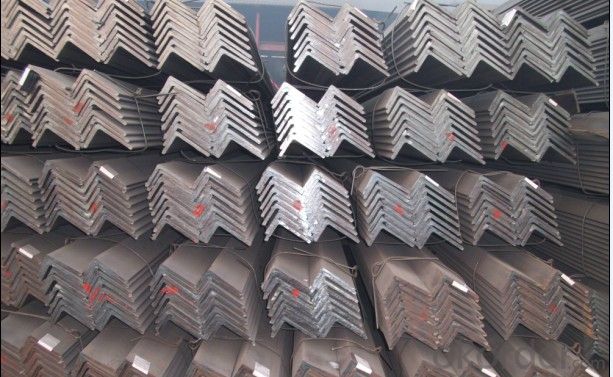

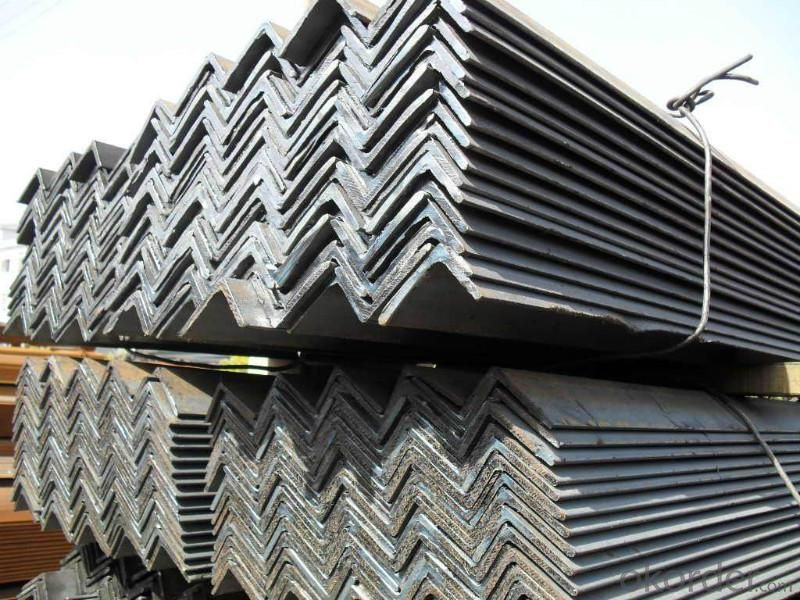

Images of Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled:

- Q: Are steel angles magnetic?

- Steel angles possess magnetic properties as they are made of steel, a ferromagnetic material. Ferromagnetic materials, like steel, can be magnetized and are drawn towards magnets. Due to the composition of steel, which includes iron and other elements, it exhibits a magnetic response. This characteristic finds practical applications in diverse fields, including construction, where steel angles are frequently employed to provide structural support.

- Q: Are steel angles available in different grades?

- Different grades of steel angles are indeed available. Carbon steel is the commonly used material for steel angles, and it comes in various grades like A36, A572, and A588. These grades possess distinct chemical compositions and mechanical properties, rendering them suitable for diverse applications. Furthermore, stainless steel angles are also obtainable in grades such as 304 and 316, which exhibit exceptional corrosion resistance characteristics. Selecting the appropriate grade of steel angle depends on specific project requirements, encompassing strength, longevity, and resistance to corrosion.

- Q: How do steel angles contribute to the overall durability of a structure?

- Steel angles, also known as angle irons or L-shaped structural steel, play a significant role in enhancing the overall durability of a structure. These versatile components are commonly used in construction projects due to their ability to provide strength, stability, and support. Firstly, steel angles are designed to withstand heavy loads and forces. By distributing the weight evenly, they help to prevent structural failures and ensure the longevity of the building. This is particularly important in applications where the structure is subjected to dynamic forces such as wind, earthquakes, or heavy machinery. Moreover, steel angles serve as effective reinforcements in critical areas of a structure. They are often used to reinforce connections between different structural members, such as beams and columns, creating a robust framework. This reinforcement enhances the overall load-bearing capacity of the structure, allowing it to withstand greater loads without compromising its integrity. Additionally, steel angles provide lateral stability to a building. By connecting various components diagonally, they help to resist horizontal forces, such as those caused by wind or seismic activity. This lateral stability is crucial in preventing the structure from swaying or collapsing under extreme conditions, ultimately ensuring the safety of occupants. Furthermore, steel angles are highly resistant to corrosion, which is a common cause of deterioration in structures. The use of galvanized or stainless steel angles can significantly reduce the risk of rusting and subsequent degradation. This corrosion resistance contributes to the long-term durability of the structure, reducing maintenance costs and prolonging its lifespan. In summary, steel angles are essential in enhancing the overall durability of a structure due to their ability to withstand heavy loads, provide reinforcement, offer lateral stability, and resist corrosion. By incorporating steel angles into construction projects, engineers can ensure the structural integrity and longevity of buildings, ultimately creating safer and more durable spaces.

- Q: How to determine the neutral axis of the angle bar?

- The neutral axis of angle iron or channel steel needs to be calculated, but it can be checked directly.

- Q: What are the common surface treatments for steel angles to enhance corrosion resistance?

- The common surface treatments for steel angles to enhance corrosion resistance include galvanizing, painting, and powder coating.

- Q: Can steel angles be used for machine frames?

- Yes, steel angles can be used for machine frames. Steel angles are commonly used in construction and engineering applications due to their strength, versatility, and cost-effectiveness. When used in machine frames, steel angles provide structural support and stability. They can be easily welded or bolted together to create a rigid frame structure that can withstand heavy loads and vibrations. The angular shape of steel angles also allows for easy attachment of other components or accessories. Overall, steel angles are a popular choice for machine frames due to their durability and suitability for various industrial applications.

- Q: Can steel angles be used for sign posts?

- Yes, steel angles can be used for sign posts. Steel angles are commonly used for their durability and strength, making them suitable for supporting signs and providing stability in various outdoor conditions.

- Q: Are there any environmental benefits of using steel angles?

- Yes, there are several environmental benefits of using steel angles. Firstly, steel is one of the most recycled materials in the world. When steel angles are no longer needed, they can be easily recycled into new steel products, reducing the demand for new steel production. This recycling process requires less energy and resources compared to producing steel from raw materials, resulting in significant energy savings and reduced carbon emissions. Additionally, steel is a durable material that has a long lifespan. This means that steel angles require less frequent replacement compared to other materials, reducing the amount of waste generated. The durability of steel also means that it requires less maintenance and repairs over time, further reducing its environmental impact. Furthermore, steel is resistant to fire, pests, and rot, reducing the need for chemical treatments and preservatives that can be harmful to the environment. Steel angles also have high strength-to-weight ratio, meaning that less material is required to achieve the same structural integrity compared to other materials. This not only reduces the amount of raw materials needed but also decreases transportation costs and fuel consumption during construction. Lastly, steel is highly versatile and can be used in a wide range of applications, from construction to manufacturing. This versatility allows for the creation of innovative and sustainable designs that optimize energy efficiency and reduce environmental impact. For example, steel angles can be used in the construction of energy-efficient buildings that incorporate renewable energy systems, reducing overall energy consumption and greenhouse gas emissions. Overall, the use of steel angles offers several environmental benefits, including reduced energy consumption, lower carbon emissions, decreased waste generation, and increased durability. These factors make steel angles a sustainable and environmentally-friendly choice for various applications.

- Q: Can steel angles be used in machine frames?

- Yes, steel angles can be used in machine frames. Steel angles are commonly used in construction and engineering projects due to their strength and durability. They can provide structural support and stability to machine frames, ensuring their stability and resistance to loads and vibrations. Steel angles can be welded or bolted together to form rigid and stable frames, making them an ideal choice for machine frames that require high strength and stability. Additionally, steel angles are readily available in various sizes and thicknesses, allowing for flexibility in design and customization of machine frames to meet specific requirements.

- Q: What are the common methods of joining or connecting steel angles together?

- Common methods of joining or connecting steel angles together include welding, bolting, and using angle brackets or cleats.

Send your message to us

Unequal Angle Steel High Quality Q235 Jis SS400 Hot Rolled

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches