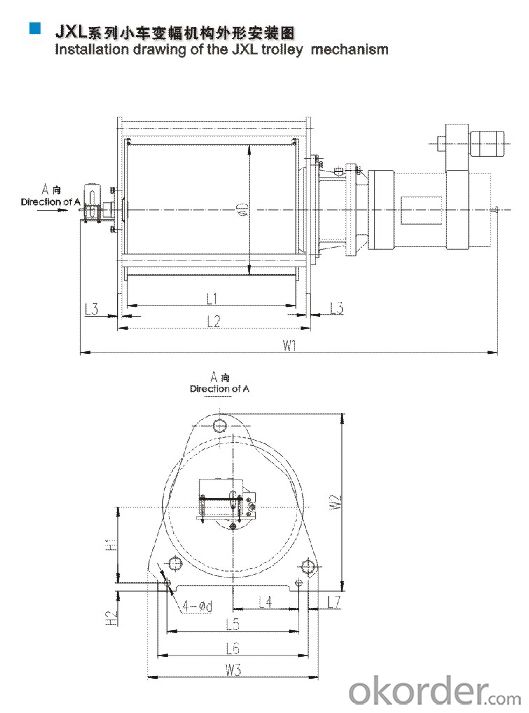

trolley mechanism 95JXL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

The JXL trolley mechanism is a self-designed new product based on the advanced foreign technology, and got the national utility mode patents.

The JXL trolley mechanism constitutes torque motor, half built-in planetary reduction gear wound roll, rack, and other components, which has advantages of smooth shift from the brake, transmission efficency, low noise, compact structure, and brakeing safe, reliable, accruate positioning, pleasing in appearance, and other characteristics.

After changing variable-frequency speed regulation motor and electronic system, the institutions can be changed to JXF trolley mechanism, which has the advantages of zero velocity brake, starting speed more stable and is more suitable to large tower crane and the trolley running on a demanding place.

Performance parameters

Model:95JXL

Rated stalling torque of torque motor(N.m):95

Rated single rope tension (N):4500

Single-rope linear velocity(m/min):0-58

Rope capacity(m):63

Wire rope diameter(mm):7

Relevant parameter of the suitable tower crane

--Max lifting load(t):10

--Max crest(m):65

- Q: don't its wheel provide the same amount of friction?

- To make it harder for them to tip over.

- Q: All types of jack up cranes. How is the maximum lifting torque converted?

- The moment of the tower crane is set up by the factory, and can not be changed. How do you want to convert it?If the nominal torque is converted to kn tons, 1 tons is equal to 9.8 kn.

- Q: Like the tall cranes on construction sites. I mean, suddenly they're just magically there!

- No I can't say I have ._.

- Q: for my homework : the question was explain how a skyscraper crane uses physics moments but no where can i find out the answer and dont want a detention ekkk x

- OK... So what has your homework actually asked you to explain? Can you post the question...? There are moment forces going through a crane, is the aim of the homework simply for you to explain what a moment force is using a specific example ? A crane can be thought of in simple terms as a cantilever, ie one supported end and one free end, the lever arm force as it is sometimes referred to in schools is actually the moment force i.e. the moment for a crane with a boom L=40m long lifting a load of P=10kN would beP*L = 10*40 = 400 kNm, this is ignoring the self weight of the boom, if the boom weighed W=1.5kN/m (thats per meter, not to be confused with kNm which is kilo newton meters) then the moment generated by the self weight would be (WL^2)/2 = (1.5*40^2)/2 = 1200kNm so the total moment would be 1600kNm, so just remember for a point load the moment is force * distance from support ( in cantilevers) hope this helps... :)

- Q: I've been making lots of paper cranes lately, thinking I would know exactly what to do with them. In reality, I'm a bit short on ideas... Can you help me with this, because I'd love to find ways to decorate my room with them. I can't really use nails on my walls or ceiling, so I can't do a mobile or randomly string them about.

- Okay - so if you can't string them from the ceiling - than what I would do is buy some round vases/globes, from Pier one or some place like that, and fill them with paper cranes, then set the bowls on your shelves/windowsill/desk/table or other flat surface. I've enclosed some examples below. You can also make a mobile by hanging something like a super strength hook with adhesive. 3M makes them (the same folks who created scotch tape). The adhesive does not damage walls and you can stick them to anything. They can bear up to 30 pounds of weight. Put a few on your ceiling or walls and hang your mobiles from them.

- Q: I was wondering if Steam Cranes are still used to clear train derailments or are the all mothballed now? What do they use to clear derailments now days if the not the Steam Cranes? Also way are there 2 types of hooks on the crane anyway? Thanks

- I would think it is run by diesel,or electric.

- Q: How do you apply for it? What are the specific requirements?

- These do not worry about you, these large machinery is a professional installation team, security, demolition,

- Q: why do whooping cranes migrate? If its because its to cold in the winter then why not stay in the warm weather?

- It is freezing cold in the upper Midwest during the winter. Whooping cranes simply cannot find any food, even if they can endure the cold. During the summer, the upper Midwest has longer daylight hours and slightly cooler temperatures. than their wintering grounds in Florida. The longer hours allow them and their young more time to gather food. Reproduction is very taxing on the female body, even if it is just laying eggs. The young need the extra time and nutrition to grow quickly into adult sized birds. Small birds are more vulnerable to predators.

- Q: i have a female Doberman 4months old. running here n there, we spend time with her morning and night, four days per week we go to a big ground and walking with her more than a hour per day, is it adequate? she seems very happy and waiting for us on every evening (me and my wife) also i need an advice on her crane? i have put her in some what big (5ft 4ft) place beside my front door, not fully covered but well sheltered by the house roof/. is it ok to have an open crane like that?

- I have no idea what an open crane is? Do you mean you leave her outside all day? If so, the answer is no. Dobermans don't have the right type of coat to be left outside all day even with shelter.

- Q: What are the differences between the tower crane and the lift?

- Tower cranes are a common fixture at any major construction site. They're pretty hard to miss -- they often rise hundreds of feet into the air, and can reach out just as far. While, Lift is the force that directly opposes the weight of an airplane and holds the airplane in the air. So, first answerer is right they not something alike.

Send your message to us

trolley mechanism 95JXL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords