Tower Crane Spare Parts TC4808 CMAX Brand

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Detail of Tower Crane

Feature:Tower Crane

Condition:New

Model Number:TC4808(QTZ40)

Place of Origin: China (Mainland)

Brand Name: CMAX

Certification: ISO,CE

Warranty: 1 Year

Application:Building,Construction,Industrial

Main Features of Tower Crane

1) This kind of crane adopts standard section hydraulic lifting and connecting.The max. height can reach 180m with wall tie ins.

2) It has high working speed, good speed-adjusting performance, steady operation and high efficiency. Three-speed motor and mono-speed ratio decelerator are applied in the lifting struction, which enables heavy load low speed and light load high speed.

3)The range-change structure drives the trolley moving on the horizontal crang jib, with good positioning performance. Planet gear decelerator is applied in the circumgyrating structure, together with moment-limiting hydraulic coupler, which can relize high load capacity, steady starting and reliable operation.

4) The crane has complete set of safety devices, which can guarantee the safe and high efficienct operation. The crane is equipped with lifting height limiter, trolley ranging limiter, moment limiter, weight limiter etc..

5)The cranehas scientific layout and handsome appearance. The drivers cab is set independently on one side, with good vision field. It creates a good working environment for the operator.

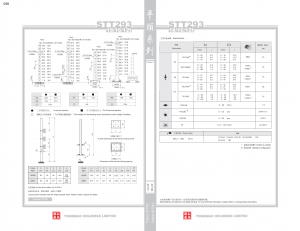

Specification of Tower Crane

Independent height (m) | 31.5 | ||||||

Max height with attachment (m) | 110 | ||||||

Working range can be adjusted(m) | 38、43、48 | ||||||

Min working range(m) | 2.25 | ||||||

Max lifting capacity(t) | 4 | ||||||

Tip load @ 48m(t) | 0.8 | ||||||

Hoist mechanism | Falls | 2 | 4 | ||||

Lifting capacity(t) | 1 | 2 | 2 | 2 | 4 | 4 | |

Speed(m/min) | 70 | 35 | 7 | 35 | 17.5 | 3.5 | |

Motor | YZTD225M2-4/8 /32 15/15/3.5KW | ||||||

Trolleying mechanism | Speed(m/min) | 20/40 | |||||

Motor | YDEJ100-4 /8 2.4/1.5KW | ||||||

Slewing mechanism | Speed(r/min) | 0-0.6 | |||||

Motor | YD132S-6/8 2.4/1.8KW | ||||||

Climbing speed(m/min) | 0.4 | ||||||

Counterweight(t) | 7.6 | ||||||

Mast section size(L×W×H)m | 1.4×1.4×2m | ||||||

Working temperature | -40-+60℃ | ||||||

Total power (KW) | 23 | ||||||

Power supply requirement (KVA) | 115KVA for generator | ||||||

Cable type ( within 30 meters from site power source to lower electric box of tower crane ) | |||||||

Startup voltage & current | 380V×95%=361V 180A | ||||||

Rated working voltage & current | 380V 65A | ||||||

Loading diagram:

48m jib length:

R | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | |||||

a=2 (t) | 2t---20.7m | 1.87 | 1.70 | 1.56 | |||||||||

a=4 (t) | 4t—10.95m | 3.61 | 3.04 | 2.62 | 2.30 | 2.04 | 1.84 | 1.67 | 1.53 | ||||

R | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | ||

a=2 (t) | 1.44 | 1.34 | 1.24 | 1.17 | 1.09 | 1.03 | 0.98 | 0.93 | 0.88 | 0.84 | 0.80 | ||

a=4 (t) | 1.41 | 1.31 | 1.21 | 1.14 | 1.06 | 1.00 | 0.95 | 0.9 | 0.85 | 0.81 | 0.77 | ||

43m jib length:

R | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | |||||

a=2 (t) | 2t---21.2m | 1.92 | 1.75 | 1.61 | |||||||||

a=4 (t) | 4t—11.25m | 3.72 | 3.13 | 2.7 | 2.37 | 2.10 | 1.89 | 1.72 | 1.58 | ||||

R | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 43 | ||||

a=2 (t) | 1.48 | 1.37 | 1.28 | 1.20 | 1.13 | 1.06 | 1.01 | 0.95 | 0.93 | ||||

a=4 (t) | 1.45 | 1.34 | 1.25 | 1.17 | 1.10 | 1.03 | 0.98 | 0.92 | 0.9 | ||||

38m jib length:

R | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | |||||

a=2 (t) | 2t---21.9m | 1.99 | 1.81 | 1.66 | |||||||||

a=4 (t) | 4t—11.58m | 3.84 | 3.23 | 2.78 | 2.44 | 2.17 | 1.96 | 1.78 | 1.63 | ||||

R | 28 | 30 | 32 | 34 | 36 | 38 | |||||||

a=2 (t) | 1.53 | 1.42 | 1.32 | 1.24 | 1.16 | 1.10 | |||||||

a=4 (t) | 1.50 | 1.39 | 1.29 | 1.21 | 1.13 | 1.07 | |||||||

Images of Tower Crane

FAQ about Tower Crane

Q: What serice you could provide?

A: Providing timely delivery, standby engineers are ready to slove any of your problem

Providing all-embraced warranty of products quality, worksite installation guidance

Providing ample spare parts and training of operation and maintenance

Engineers have more than 20 years' experience in tower crane, ready to solve any of your problems.

Q: What kind of steel used for tower crane ?

A: Normally, as for the main force bearing steel structure, Q345B is adopted; as for the assistance force bearing steel structure Q235B is adopted. All of the raw material is outsourced from qualified steel factory in China.

Q: What about our tower crane warranty?

A: Usually there is one-year quality warranty including main electronic parts (not including consumable parts). There are consumable spare parts together with whole machine and normally they are enough for one year.

Q: What is 3 main mechanism of the tower crane ?

A: there are trolleying mechanism/ slewing mechanism/ hoisting mechanism.

Q: Can you equip with light on tower crane jib, monitor, remote control and anemometer?

A: Sure. All of these could be provided with extra cost upon the clients' requirements. But according to general practice, remote control is not suggested because most of the operator feedback operation in the cabin will provide a wide working view.

- Q: What are the luffing, slewing, and walking points of a tower crane?

- The luffing of a tower crane is the forearm of a crane;Slewing means the steering mechanism of a crane;Walking means the walking trolley on the luffing range of a crane

- Q: A solid answer and links would be nice.Your help and/or attempts to help are appreciated

- www.pacificfriend.ca/html/one_tho... This site will give you the story of the Japanese girl during the time of WWII. It is a touching story.

- Q: Please try to give information on the questions bellow: .What the climate was in the Japanese Crane's habitat (high, lows, averages, precipitation) . Plants in the Japanese crane's habitat .2-3 major animals in its habitat .2-3 minor animals in its habitatTHANK YOU SO MUCH!!! .

- in the east Hokkaido, the north island of japan. some japanese crane in russia goes to north korea in winter, but cranes in hokkaido stay all through the year.

- Q: Safety rules for tower cranes

- Three. Check after shutdown3.1 after the tower crane has stopped operation, it is necessary to select the suitable position of the barrier and the middle of the track when the turret is turned and the arm to stop along the wind, and then lock all the rail clamps.All 3.2 tower crane rotary mechanism with a normally closed or braking device, in the stop after the operation, the driver must remove the handle, release the brake for crane in the wind blowing in under the direction of rotation.3.3, the hook should be lifted to the minimum distance from the lifting wall, not more than 5m position, hanging on the hook is strictly prohibited. Not to take reliable measures, not by any means, limiting the boom rotate with the wind.

- Q: A. to make everyone become a CommunistB. to become rich at the expense of othersC. to kill all the villagersD. nothing in particular

- The main idea of Cranes by Hwang Sun-Won is more of a symbolic thing; he uses different objects such as chestnuts and cigarettes, as well as the cranes in the story to convey his hope and his dream, along with his message. He is expressing the power of war, particularly civil war, which can rip apart families, neighbors and the best of friends. The story, unlike many other tragic civil war tales, is not focused on the idealogical difference btw Tok-Chae and Song-Sam. Rather, it is about the human tragedy of the Korean War. Tok-Chae and Song-Sam were ripped apart by the War. Song-Sam, on his return to his village, he finds Tok-Chae and decides to escort him to a Public Peace Police office a few miles away. On the way, he gets flashbacks and talks with Tok-Chae. These things help to change his mind and he frees Tok-Chae. This is symbolized by the two cranes which soared high into the sky. Hwang-Sun Won conveys his message effectively; unification will be achieved and is needed to repair such ties like Tok-Chae and Song-Sam. He is saying that the two cranes will fly together once more.

- Q: I have a crane fly in my room. I know they don't bite but do they bother people or tend to completely avoid them? I can't find it and I'm going to sleep soon.

- This is a new one on me. It's bad enough we have the urban legend that the arachnid daddylonglegs is poisonous (it isn't), now we have the confusion extending to the insect also. Daddylonglegs as a name for a mosquito-like insect is a term used in Britain. What is called a daddylonglegs in the United States is the arachnid which is often mistaken for a spider. It can be distinguished from a spider by the fact that it does not have a narrow waist as a spider has. Also it has no venom glands. The confusion is further extended by the fact that there is a type of true spider which is sometimes called a daddylonglegs spider!. It is in the family Pholcidae and is more commonly called cellar spider.

- Q: Tower crane 4 how to change the rate of 2 magnification, how to change, say detailed points

- At this point, the rope will be turned into 2 fold!Some manufacturers produce pulley, also need to be in the car, and then the magnification pulley with pin shaft fixed in the car!

- Q: well I am making 1000 paper cranes... I am on 18... but how do you string them all together anyone know?

- You poke a hole in them and string them....

- Q: It's better if the explanation is not complicated.TQ

- Hello, 1. Modularity: You can build ships (larger ships) in modular sections and have the crane lift these modular sections and put them into place for final assembly. This is one major advantage that was not available back in the day

- Q: A 3000-lb wrecking ball hangs from a 40-ft cable of density 10 lb/ft attached to a crane. Calculate the work done if the crane lifts the ball from ground level to 40 ft in the air by drawing in the cable.

- The total work done by the crane equals the potential energy gained by the wrecking ball and the cable; the potential energy gained is W = V_final = Mg L + ρ L g L/2 which is the final potential energy of the wrecking ball and the cable added together. In the case of the cable, you take the center of mass of it which is located right at the center (L/2). The result is then W = 3000*32*40 + 10 * 40 * 32 * 40 / 2 = 4096000 ft-lbf = (4096000)*(0.001285067) BTU = 5263.63 BTU

Send your message to us

Tower Crane Spare Parts TC4808 CMAX Brand

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords