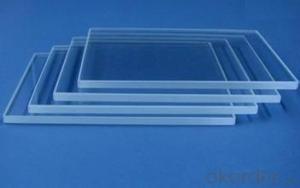

Toughened glass Security features 12mm-18mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestation

Provide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: Why does the endothermic glass be cool in winter and cool

- Summer architectural glass membrane can block up to 85% of the solar heat into the indoor UV blocking rate of not less than 99% and has good light transmission. Winter to prevent more than 50% of the indoor heat dissipation outflow, so that the indoor and outdoor temperatures are significantly different, Dongnuanxialiang, so that consumers save air conditioning or heating power consumption brought about by the high tariff.

- Q: I want to build a coffee table for my girlfriend but I was thinking about doing a glass inlay with neon pink tube lighting underneath the glass to make it glow.Thanks in advance to whoever responds!

- You are probably tired of looking through stacks and stacks of projects on woodworking in magazines and books of all kinds for some instructions on how to do a certain project.

- Q: What are the types of glass?

- Hot-melt glass, also known as crystal three-dimensional art glass, is currently beginning in the decoration industry in the emergence of a new family. Hot-melt glass from Western countries, in recent years to enter our market. Previously, China's market are foreign products, Glass manufacturers to introduce foreign hot melt furnace production products. Hot-melt glass with its unique decorative effect as the design unit, the glass processing owners, decorating the owner of the attention of the focus.Film glass across the existing glass form, give full play to the designer and craftsman's artistic conception, the modern or classical Of the art form into the glass, so that the processing of a variety of flat glass bumps, color different artistic effects.

- Q: I got one of those oil burners that holds a tea light candle on the bottom and has a glass bowl on top to put in a few drops of essential oil. The glass bowl has built up a brown residue from the burned up oil and I have tried everything to get it off, including rubbing alcohol and WD-40 but nothing has worked, does anyone know how to remove it?

- You might also try soaking overnight in water with either some ammonia, or dishwasher detergent.

- Q: What kind of new glass is there now?

- There are: folder wire mesh anti-theft glass, there is a folder silk glass, discoloration glass, eat glass, heat-absorbing glass

- Q: Find the role of several new glass features, to concentrate a little Hurry Short point, a little concentration, tomorrow to use acridine!

- Safety glass is compared with ordinary glass, with high mechanical strength, impact resistance of the glass. Its main varieties are tempered glass, laminated glass, laminated glass and titaniumized glass. Safety glass is crushed, the debris will not hurt, and both anti-theft, fire function. According to the production of glass used in the original film does not, safety glass has a certain decorative effect.

- Q: Instead of spending thousands of dollars on new windows in certain areas i am going to build my own for sheets of glass and metal/wooden framing. Is there anyone out there who knows of a decent diy window project site or book. I am going to try and make the windows as energy efficient as possible and i would like to know any ways this might be achieved.any help would be greatly appreciated.

- Thermo-panes are the real trick and you cant make those yourself.. They must be completely sealed and full of inert gas such as argon, to keep moisture from forming between them. You can build the frames, jambs and mouldings yourself, but order the thermo-panes from a professional glass shop.

- Q: Through the glass after the sun came in with the glass can not be compared to those who will be the skin of the sun more black ah? Seek experts

- So that the skin is black, is the sun in the ultraviolet. Ultraviolet rays are wavelengths shorter than visible light. The wavelength is between 390 and 400 nm. It can pass through the air, but it is not easy to pass through the glass, has the ability to sterilize, and has some damage to the eyes and skin.

- Q: I only understand the price of the car film, and now the family would like to film, and would like to know about the price of building film, please know friends tell! Incidentally, in Changsha, better insulation film, thank you!

- There are a lot of building film online ah! You can go to the Internet to check, our home is the US-based brand of film! Also bought online!

- Q: Glass for building construction mainly.

- It's not one of our main products, so probably a little here, a little there.

Send your message to us

Toughened glass Security features 12mm-18mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords