Torched Sbs/app Waterproofing Bitumen Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

SBS modified bitumen waterproof membranes use high quality needle punched polyester mat or fiberglass compound mat as the base reinforcement. And use SBS modified bitumen as the dip-coat material. The SBS modified bitumen waterproof membrane are widely used for roof waterproof projects.

Specifications

1. Width: 125px-1m or as customized

2. Length: 3m/5m/10m/15m/20m or as customized

3. Thickness: 2mm/3mm/4mm/5mm

4. Surface: PE film, Colorful Sand, Mineral Granules or Aluminium foil

Technical Parameters

No. | Item | Index | |||||

I | II | ||||||

PY | G | PY | G | PYG | |||

1 | Solvend content(g/m²)≥ | 3mm | 2100 | - | |||

4mm | 2900 | - | |||||

5mm | 3500 | ||||||

Experiment phenomena | - | Carrier non-ignitable | - | Carrier non-ignitable | - | ||

2 | Heat risistance | °c | 90 | 105 | |||

≤mm | 2 | ||||||

Experiment phenomena | Non flow,dippage | ||||||

3 | Cold bending/°c | -20 | -25 | ||||

No crack | |||||||

4 | Waterproof 30min | 0.3MPa | 0.2MPa | 0.3MPa | |||

5 | Tensile strength | Maximum peak tensile(N/50mm)≥ | 500 | 350 | 800 | 500 | 900 |

Inferior peak tensile (N/50mm)≥ | - | - | - | - | 800 | ||

Experiment phenomena | In stretching process,the test specimen has no asphalt cracks or separate with the carrier | ||||||

6 | Elongation | Maximum peak elongation | 30 | - | 40 | - | - |

Inferior peak elongation | - | - | 15 | ||||

Product Feature

1. SBS modified bitumen waterproof membrane has good watertightness.

2. SBS modified bitumen waterproof membrane is high strength of extension, good ductility

3. SBS modified bitumen waterproof membrane is special used for low temperature.

4. SBS modified bitumen waterproof membrane is easy construction, can be constructed all of the year by the way of hot melt.

Application

1.Make sure the roof deck is smooth,clean and dry(Moisture<9%),then apply the surface of roof deck with a kind bitumen paint till dry.

2. There are two methods in application:

One way is by heating and melting method---Heat the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-250px.

The other way is by cold adhesive method---Pour the cold adhesive on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation as requested.

3.After application,, a full serious inspection is required,that’s to make sure no air bubble,,no fold,,no falling away etc. and guarantee the waterproof life.

Requirements for construction

1.The base should be dry and clean. Do not work in the rainy or snowy day.

2.Do not work under heavy wind(above 5 grade)

3.Unsuitable for construction below 5°C

4.If it is rain or snow in the process of construction, protective measure to the laid membrane is must.

5.All the workers should put on special uniforms to keep safe when installing. There should be equipments for fire controls.

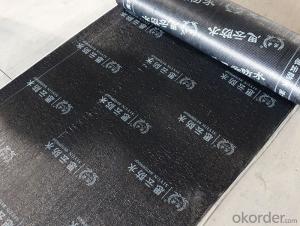

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: What is the meaning of the node and the additional layer in the construction of the membrane waterproofing layer?

- Waterproof membrane construction, the node is relative to the large area of the plane in terms of. Node parts are: yin and yang angle, the root of the pipeline, the rain shed, all kinds of flooding, expansion joints, deformation joints, construction joints, through the wall and other areas need to focus on processing.

- Q: Can waterproofing membranes be used on rooftop terraces?

- Indeed, rooftop terraces can utilize waterproofing membranes. In fact, they are frequently employed to safeguard the terrace's structural integrity and prevent water damage to the underlying structure. Rooftop terraces are exposed to diverse weather conditions, encompassing rain, snow, and UV rays, which can result in leaks and deterioration. Waterproofing membranes function as a barrier, impeding water from permeating the surface and causing harm. These membranes are specifically engineered for outdoor usage and can endure the harsh conditions commonly encountered on rooftops. They are obtainable in various materials, such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in selecting the most suitable option for a specific terrace. Moreover, waterproofing membranes can be installed beneath a variety of terrace finishes, including pavers, tiles, and decking, offering a versatile solution for diverse design preferences. Overall, it is highly advisable to employ waterproofing membranes for rooftop terraces to ensure their longevity, durability, and resistance to water-related problems.

- Q: Can a waterproofing membrane be used for a bathroom?

- Yes, a waterproofing membrane can be used for a bathroom.

- Q: How does a waterproofing membrane adhere to the surface?

- A waterproofing membrane adheres to the surface through a combination of mechanical and chemical bonding. The membrane is typically applied using a specialized adhesive or primer that helps create a strong bond between the membrane and the surface it is being applied to. The mechanical bonding occurs as the adhesive or primer penetrates into the pores of the surface, creating a physical bond between the membrane and the substrate. This helps ensure that the membrane is securely attached and able to withstand the forces it will encounter. Chemical bonding also plays a crucial role in the adhesion process. The adhesive or primer contains chemicals that react with the surface, forming chemical bonds with the membrane. This chemical reaction helps create a durable and long-lasting bond that can withstand environmental factors such as temperature changes, moisture, and UV exposure. Additionally, the composition of the waterproofing membrane itself plays a role in its adhesion. Many membranes are made of materials with inherent adhesive properties, such as bitumen or rubberized asphalt. These materials have natural tackiness, which allows them to adhere to the surface without the need for additional adhesives or primers. Overall, the adhesion of a waterproofing membrane to a surface is a combination of mechanical and chemical bonding, achieved through the use of specialized adhesives or primers. This ensures a strong and durable bond that effectively protects the surface from water damage.

- Q: Can a waterproofing membrane be used for planter boxes?

- Indeed, planter boxes can benefit from the utilization of a waterproofing membrane. The main purpose of a waterproofing membrane is to obstruct the passage of water through various surfaces, making it an effective remedy for safeguarding the planter box and its surroundings against water damage. When a waterproofing membrane is installed internally within the planter box, it establishes a protective barrier that prevents water from infiltrating the underlying materials, such as wood or concrete, thus prolonging the lifespan of the planter box. Furthermore, the presence of a waterproofing membrane can also assist in retaining moisture within the planter box, which proves advantageous for the plants thriving inside. Nonetheless, it is crucial to exercise caution when selecting a waterproofing membrane, ensuring that it is specifically tailored for planter boxes and poses no harm to the plants, thereby guaranteeing optimal outcomes.

- Q: Can a waterproofing membrane be used on tunnels with security systems?

- Yes, a waterproofing membrane can be used on tunnels with security systems. The waterproofing membrane is designed to protect the tunnel structure from water infiltration and damage, and it can be installed without interfering with the security systems in place.

- Q: Can a waterproofing membrane be used in residential or commercial structures?

- Yes, a waterproofing membrane can be used in both residential and commercial structures. Waterproofing membranes are designed to create a barrier that prevents the penetration of water into the structure. They are commonly used in areas such as basements, foundations, roofs, and bathrooms to protect the building from water damage. In residential structures, waterproofing membranes can help prevent water leaks, mold growth, and structural deterioration. In commercial structures, they are often used to protect valuable assets, such as equipment and inventory, and to maintain a safe and healthy environment for employees and customers. Additionally, waterproofing membranes can be applied to both new construction projects and existing structures, making them a versatile solution for any type of building.

- Q: Can a waterproofing membrane be used on below-grade walls?

- Indeed, a waterproofing membrane is capable of being employed on walls located below ground level. In fact, it is highly advisable to utilize a waterproofing membrane on such walls so as to shield them against infiltration of water and potential harm caused by moisture. Walls situated below ground level are especially susceptible to water penetration due to their proximity to the ground and the possibility of hydrostatic pressure. A waterproofing membrane serves as a protective barrier, effectively preventing water from seeping into the walls and leading to issues such as mold, mildew, decay, and structural impairment. Moreover, it aids in maintaining the interior of the edifice in a dry condition, thereby averting potential problems related to moisture.

- Q: Can a waterproofing membrane be used for restaurants or kitchens?

- Yes, a waterproofing membrane can be used for restaurants or kitchens. Waterproofing membranes are commonly used in these areas to protect the underlying structure from water damage. They are typically installed in areas prone to water exposure such as floors, walls, and countertops. Waterproofing membranes help prevent water from seeping into the building materials, which can cause deterioration, mold growth, and other issues. Additionally, these membranes are designed to be resistant to chemicals and stains commonly found in restaurant or kitchen settings. Overall, using a waterproofing membrane is an effective way to ensure the durability and longevity of the restaurant or kitchen, while also maintaining a clean and hygienic environment.

- Q: Can a waterproofing membrane reduce noise transmission?

- Indeed, noise transmission can be diminished by employing a waterproofing membrane. These membranes, usually composed of sound-insulating materials like rubber or synthetic polymers, when applied to various surfaces, establish a barrier that absorbs or obstructs sound waves. Consequently, the amount of noise able to permeate the structure is reduced. Moreover, these membranes serve the purpose of sealing gaps and cracks in walls or floors, thereby decreasing noise leakage. Hence, while their primary function is to prevent water infiltration, waterproofing membranes also offer the secondary advantage of lowering noise transmission.

Send your message to us

Torched Sbs/app Waterproofing Bitumen Membrane

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 44 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords