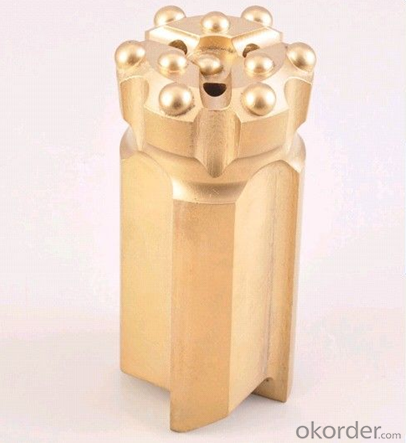

thread button bit from China R32 T38 T45 T51

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Thread Button Bits: High quality and several thread with various carbide tips like YK05 are available. All products can be developed upon customers' request. Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity, Excellent straightness and hole clean quality, Get max. drilling performance for rock drills with long life to save up fuel cost rate.

Description of button bit:

Our company supply all kind of button bits with Rope thread

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.more

Specification of button bit:

Thread | Diameter range | Skirt Design | Face Design | Button Design |

R22 | 35 – 45mm | Normal | Flat Face Drop Centre | Hemispherical Ballistic |

R25 | 33 – 57mm | Normal | Flat Face Drop Centre | Hemispherical Ballistic |

R28 | 36 – 51mm | Normal | Flat Face Drop Centre | Hemispherical Ballistic |

R32 | 41 – 89mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

R35 | 48 – 51mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

R38 | 64 – 102mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

T38 | 57 – 102mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

T45 | 70 – 127mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

T51 | 76 – 140mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

T60 | 89 – 140mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

ST58 | 89 – 140mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

GT60 | 93 – 140mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic |

ST68 | 102 – 152mm | Normal Retrac | Flat Face Drop Centre | Hemispherical Ballistic Conical |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q: The difference between steel teeth and inserted cone bit

- When drilling rig, drive turntable, Kelly, drill pipe and the drill bit rotation, through the drill ground instrument to observe the work of underground drill, after a comprehensive judgment, if you think the drill has been worn, it should immediately stop drilling to replace the roller bit, a bit of oil, insert bit, steel tooth drill, drill wells. PDC bit, diamond drill etc.

- Q: What drill holes are used to break the screw?

- The metal, its principle is to discharge at the moment, a sharp change of arc temperature and with pressure, so that the metal material of the point immediately melted, gasification, splashed liquid and explosive, condensed into solid particles is the working fluid. At this time, the metal surface is etched into a pit, so EDM can be easily processed on any metal workpiece, so it is convenient and quick.

- Q: What are the differences between the center drill and the twist drill in its structure and use?

- Center drill: prefabricated, precise positioning for hole processing and central hole machining on end faces of shafts and shafts. Guide the twist drill to reduce the error.

- Q: Tap with 5 taps. How many drills are drilled?

- Generally, a drill with a 4 cm bit.

- Q: What is the standard angle of the drill bit?

- For example, the processing of aluminum parts is generally 118 degrees, because the processing of aluminum parts require fast feed, in the processing of small head angle of the cutting parts of the force will spread to the left and right sides, easy to cut. Casting angle of general 140-145, such as feed reasons for the high hardness of cutting force is slow, mainly concentrated in the front edge, if the bit is too sharp will wear out quickly, and the blade angle blade angle relative small blade due to natural force will be small and short.

- Q: Small bit drilling, drilling machine speed is fast or slow?

- This size is easy to guarantee. A drill bit is to make two cutting edges for the small angle grinding symmetry, if you want to drill the round, can put some small angle grinding, namely some sharp, this bit in drilling, centering is better, the hole wall is relatively light.

- Q: At present, the strongest oil drill bit, the deepest can drill how many meters?

- Correspondingly, the specifications of ultra deep drilling machine can be divided into 6000 meters, 7000 meters, 8000 meters, 9000 meters, 10000 meters, 12000 meters and 15000 meters. The United States is the country with the longest history, the largest workload and the highest technology level in the world. It also has the largest number of deep drilling rigs. There are about more than 90 more than 9000 meters deep drilling in the world, the United States accounted for more than 80, of which 8 drilling more than 10668 meters deep.

- Q: What do you mean by 5 times diameter drill?

- The length of the chip slot is 5 times the diameter of the drill bit.5 times a bit is the drill depth that can reach 5 times the diameter of the drill. For example, a drill with a diameter of 10 can process 50 deep holes.

- Q: Construction drills, woodworking drills, high-speed steel drills, shapes and uses, what's the difference?

- A construction bit, a carpenter's drill, has the same diameter as a shank and is longer than a bit of a high-speed steel.High speed steel drill stem generally 3.175mm diameter, see need, more than 6.5mm rarely.The drill bits in 3 are of different materials

- Q: What chisel drills are used for building water utilities?

- Don't say to yourself why, before all the impact drill plus tip and flat chisel and hammer, impact drill with open ditch, then with hammer and chisel out the middle left

Send your message to us

thread button bit from China R32 T38 T45 T51

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords