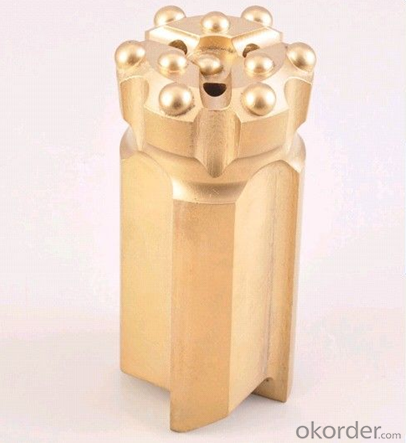

thread button bit from China dia 35-45mm R22

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are specialized in rock drilling tools,such as taper button bit, thread button bit, Integral drill rod, DTH bit, DTH hammer, Air leg rock drill, Excavator Mounted rock driling and splitter, expansive mortar.

Product:

Thread Button Bits: High quality and several thread with various carbide tips like YK05 are available. All products can be developed upon customers' request. Premium designs and steel and premium tungsten carbide insert grade T6 supplied by Boart Long year, Offers industry-leading strength and penetration rates for more productivity, Excellent straightness and hole clean quality, Get max. drilling performance for rock drills with long life to save up fuel cost rate.

Description of button bit:

Our company supply all kind of button bits with Rope thread

R32-43MM, R32-45MM, R32-51, R32-64, R32-76;

T38-64, T38-76MM, T38-89, T38-102MM;

T45-76MM, T45-89MM, T45-102MM;

T51-89MM, T51-102MM, T51-127MM etc.

all face design, flat face, drop-center face, normal body and retrac body.more

Specification of button bit:

Thread | Diameter range | Skirt Design | Face Design | Button Design |

R22 | 35 – 45mm | Normal | Flat Face | Hemispherical |

R25 | 33 – 57mm | Normal | Flat Face | Hemispherical |

R28 | 36 – 51mm | Normal | Flat Face | Hemispherical |

R32 | 41 – 89mm | Normal | Flat Face | Hemispherical |

R35 | 48 – 51mm | Normal | Flat Face | Hemispherical |

R38 | 64 – 102mm | Normal | Flat Face | Hemispherical |

T38 | 57 – 102mm | Normal | Flat Face | Hemispherical |

T45 | 70 – 127mm | Normal | Flat Face | Hemispherical |

T51 | 76 – 140mm | Normal | Flat Face | Hemispherical |

T60 | 89 – 140mm | Normal | Flat Face | Hemispherical |

ST58 | 89 – 140mm | Normal | Flat Face | Hemispherical |

GT60 | 93 – 140mm | Normal | Flat Face | Hemispherical |

ST68 | 102 – 152mm | Normal | Flat Face | Hemispherical |

Company Profile:

CNBM is the largest state-owned enterprise in China building material & equipment industry. Up until October of 2011, our total assets exceeded RMB 190 billion, with 130,000 employees and over 300 subordinate companies. In the year 2012, we are ranked as No. 365 in World Top 500 Enterprises by Fortune, and No. 2 in global building materials industry, second only to Saint-Gobain.

FAQ:

1. Q: Can I get some samples?

A: We are honored to offer you samples for quality check.

2. Q: Do you have the products in stock?

A : Yes , We have sample for several models now could supply to you.

3. Q: What’s the delivery time?

A: It usually takes about 25 days to produce an order. But the exact delivery time might be different for different orders or at different time.

4. Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model should not be less than MOQ.

5. Q: How does your factory do regarding quality control?

A: Quality is priority. Rock drilling tools workers always attach great importance to quality control from the every beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

6. Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. Our company is world top 500, that is the biggest supplier and manufacture in China, having a good reputation around the world.

7. Q: What's the payment you accept ?

A: As usual our payment is T/T, other payment can consider.

As the largest manufacturer and exporter of building materials in China, we avail ourselves of this opportunity to approach you for mutual-beneficial cooperation. If you want to know more, pls contact me freely.

- Q: How big expansion screw does the 6mm bit have?

- 6mm drills are generally equipped with 5mm expansion screws (the smallest specification).The relationship between the drill bit and the expansion screw is the drill diameter = the expansion screw diameter +2mm. For example, the expansion screw of 6mm shall be opened with 8mm drill bit.

- Q: 1 inches of steel plate, what drill can drill through?

- Mainly used in drilling machines, lathes, flashlights and other mechanical equipment for the processing of different diameter aperture. Generally speaking, twist drills are straight shank and taper shank twist drills. Straight shank drill: suitable for drilling diameter psi below 13.0mm small diameter, taper shank twist drill for aperture and torque big hole.

- Q: How to recognize the quality of twist drills?

- In addition, there are also listening to the sound, knocking glass, using a grinding machine to play sparks, see color, etc.. These need experience, like picking watermelon, each has its own coup, different varieties, methods are also quite different. Usually, the more crisp we are, the more glass we have, the slightest spark, and the more red the spark, the better the bit material.

- Q: How do you determine the speed of the drill? Is there any standard?

- Different diameter of the drill bit, drilling speed, diameter smaller, higher speed, otherwise low;

- Q: Can an electric drill bit a wall?

- Electric shock: rotation, and hammer is different single hammer, but the hammering force is its strength. Hammer hit is out of the hole, and the hammer is empty irregular.

- Q: The drill marked difference with hammer marks

- There are signs and marks on the hammer drill bit, that this tool is the impact drill, when the adjusting knob is pointing to the side of the tool bit, only the rotation function, is also the only single drill; when the adjusting knob is pointing to the side of the tool is a hammer, impact drill function. The impact function used in wall drilling, drilling alone for wood, metal, and other drilling books

- Q: What size drills are we going to use to drill the holes in the M7 and with the larger twist drills?

- The common thread M7 second series, not commonly used, the coarse thread pitch according to the national standard of 1mm, therefore, the bottom of the thread holes at the 6mm, actually should be: the bottom hole diameter of =7-1.06p, where p is the pitch, calculated 5.94mm, underport with 6mm drill bit, not too bad. After drilling, tap with M7 tap.

- Q: 14 what big expansion wire does the drill use?

- Different expansion bolts form different drill diameters, and the maximum outer diameter of the bolt can be measured.

- Q: What is the cause of the drilling mud bit?

- The mud performance factors: poor inhibition of mud shale hydration dispersion cannot control the solid content and high viscosity; cut, drilled cuttings are difficult to remove, easy to adsorb on the surface of drill bit, if you are using solid free drilling fluid, the bit will never happen in mud; mud is high, water loss is big, easy to the formation of a rough thick mud cake; poor lubrication, the surface can not form an effective protective film, drilling fluid in solid phase adsorbed on the bit inferior.

- Q: What causes the drill bit to break at the end of the hole?

- Small bit not used high speed, with small feed amount.A small drill can withstand torque is small, the use of high speed with a small amount of feed, can reduce the small rotating cutting output, so as not to drill to bear large torque.

Send your message to us

thread button bit from China dia 35-45mm R22

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords