Rock Wool Thermal Insulating Refractory Brick for Furnace and Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal insulating refractory brick for furnace

Product Description

Introduction of refractory brick

Insulating brick is sintered mainly with supper-fine bauxite charlotte and propr additive by a method of EPS ignition loss. Refractory high alumina EPS insulating brick for heating furnace is a kind of insulation refractory product, taking bauxite as main raw material and including not less than 48% of AL2O3.

Characteristics of refractory brick

1.High porosity

2.Small volume density

3.Good insulation effect

4.High mechanical intensity

5.Small thermal conductivity

6.Long service life

Application of refractory brick

1. Building materials for blast furnace

2. Building materials for hot-blast stove

3. Building materials for coke oven

4. Building materials for steel making furnace

5. For construction material in steel industry

6. For ladle

Physical and chemical indexes of refractory brick

Brand | Clay insulating bricks | High Alumina insulating bricks | |||||

NG-0.5 | NG-0.6 | NG-0.8 | NG-1.0 | LG-0.6 | LG-0.8 | LG-1.0 | |

Bulk density g/cm3 ≤ | 0.5 | 0.6 | 0.8 | 1 | 0.6 | 0.8 | 1 |

Crushing strength Mpa ≥ | 1.5 | 2 | 2.5 | 3.4 | 1.96 | 2.94 | 4 |

The experimental temperature of linear change ≤2% | 1250 | 1300 | 1350 | 1350 | 1350 | 1400 | 1450 |

Thermal conductivity 350±25(W/m.k) ≤ | 0.18 | 0.25 | 0.35 | 0.5 | 0.25 | 0.032 | 0.45 |

Refractoriness under load | 1160 | 1250 | 1280 | 1300 | 1300 | 1350 | 1380 |

Al2O3 % ≥ | 35 | 40 | 42 | 42 | 50 | 52 | 52 |

Fe2O3 % ≥ | 2.5 | 2.5 | 2 | 2 | 1.8 | 1.6 | 1.5 |

Maximun erice temperature | 1150 | 1200 | 1280 | 1300 | 1300 | 1350 | 1380 |

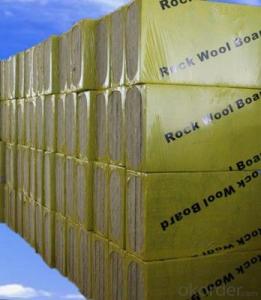

- Q: What does the rock wool board look like?

- June 1981 test success Rock wool board is a new type of insulation, fire, sound absorption material.

- Q: What role does dolomite play in rock wool products?

- Rock wool is a traditional insulation material, because it is inorganic materials, insulation performance is not very good

- Q: Rock wool products are divided into several categories

- In the rock wool by adding special adhesive can be processed into rock wool board, rock wool stave, rock wool insulation and other products, as the building insulation, insulation, cold, sound-absorbing material

- Q: How to judge the quality of rock wool

- Heat load shrinkage temperature: heat load shrinkage temperature used to characterize the rock wool board moisture and heat stability, is to wet the rock wool product samples soaked in the gradual heating of water, rock wool products at a temperature of 643 degrees will begin to shrink , So rock wool products load shrinkage temperature of 643 degrees, that is to say in the outside temperature of 643 degrees when the rock wool board will be deformed.

- Q: The difference between rock wool and rock wool

- Flexible, medium strength rock wool board: for building walls / roof insulation, fire, sound, such as curtain wall, wall partitions, elevator wells, etc

- Q: Rock wool products and aluminum silicate acupuncture blankets are same

- Rock wool products and aluminum silicate acupuncture blankets are same

- Q: Rock wool insulation material fire rating is how much

- Yanmian, mineral wool and its products are slag and basalt and other natural ore as the main raw material, the high temperature melt fiber, adding the right amount of adhesive processing

- Q: Rock wool board is inorganic composite insulation material

- Rock wool products are inorganic insulation materials

Send your message to us

Rock Wool Thermal Insulating Refractory Brick for Furnace and Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords