Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

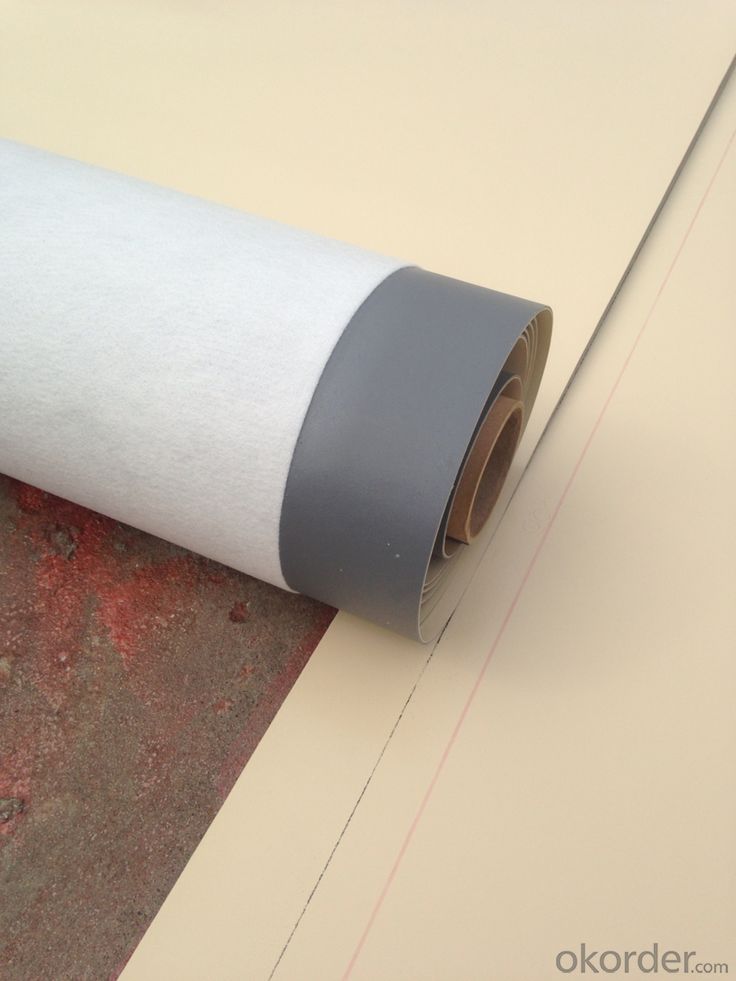

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: PVC waterproof membrane effect how

- 2, cold sticky method: the use of adhesive or miaolica for membrane and the grassroots, membrane and membrane bonding, and no need to heat the construction method.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Specific safety precautions are necessary when installing a waterproofing membrane. Consider the following key precautions: 1. Personal Protective Equipment (PPE): Installers must wear appropriate PPE, such as gloves, safety glasses, and protective clothing, to avoid skin contact with the membrane and potential chemical hazards. 2. Adequate Ventilation: Ensure that the installation area has proper ventilation to prevent the accumulation of fumes or vapors. If working in a confined space, use ventilation systems to eliminate any potentially harmful gases or odors. 3. Hazardous Chemicals: Some waterproofing membranes contain hazardous chemicals or solvents. Installers should carefully read and adhere to the manufacturer's instructions for handling and using these products. Proper storage, handling, and disposal of chemicals are crucial to prevent accidents or environmental contamination. 4. Slips and Falls: The surface can become slippery during installation, particularly when applying the membrane on wet surfaces. Installers should take precautions to maintain stability and utilize safety equipment like harnesses or guardrails when working at heights to prevent falls. 5. Heat Hazards: Proper installation of certain waterproofing membranes requires the use of heat. Installers should exercise caution when working with heat sources such as torches or heat guns to prevent burns or fire hazards. Keep fire extinguishers readily available and ensure that personnel receive adequate training on fire safety protocols. 6. Electrical Safety: Waterproofing membranes might be installed in areas where electrical systems are present. Installers should exercise caution when working near live electrical wires or outlets and adhere to proper electrical safety procedures to prevent electric shocks or fires. It is crucial for installers to undergo comprehensive training and diligently follow all safety guidelines provided by the manufacturer. This will help minimize the risk of accidents, injuries, or property damage during the installation process.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- Yes, there are several environmental considerations when using a waterproofing membrane. One of the main concerns is the potential for harmful chemicals or materials to be used in the production of the membrane. Some waterproofing membranes may contain toxic substances such as volatile organic compounds (VOCs) or heavy metals, which can have detrimental effects on human health and the environment. Another consideration is the disposal of the membrane once it reaches the end of its life cycle. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Improper disposal can lead to environmental pollution and harm to ecosystems. Additionally, the production of waterproofing membranes often requires energy-intensive processes and the extraction of non-renewable resources. This can contribute to greenhouse gas emissions and the depletion of natural resources. To mitigate these environmental concerns, it is important to choose waterproofing membranes that have been manufactured using eco-friendly materials and processes. Look for products that are labeled as low VOC or free from hazardous substances. Additionally, consider using membranes that are recyclable or made from recycled materials to reduce waste generation. Proper disposal of the membrane at the end of its life cycle is also crucial, and options such as recycling or repurposing should be explored. Overall, it is essential to consider the environmental impact of waterproofing membranes and choose products and practices that minimize harm to the environment and promote sustainability.

- Q: SBs waterproof cold sticky how to do?

- 3, the node sealed processing. To be the primary treatment agent after drying, the first outlet, the root of the pipe and other vulnerable parts of the leakage, in the radius of 200mm range, even brush a layer of adhesive, brushing thickness of about 1mm is appropriate. Paste a layer of polyester fiber after the non-woven fabric, and in the non-woven cloth and then brushing a 1mm thick adhesive. After drying to form a layer of sealing layer.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Zoos or aquariums can definitely utilize waterproofing membranes. These membranes are specifically designed to create a protective barrier against water infiltration, making them an excellent choice for preventing water damage and leakage in such environments. They can be applied to different surfaces, such as concrete or steel, to establish a watertight seal and prevent water from seeping into the structure or habitat. Aquariums often rely on waterproofing membranes to ensure that their tanks remain completely watertight and free from leaks, as this is crucial for the well-being of the aquatic animals. Similarly, in zoos, waterproofing membranes can be applied to animal enclosures or exhibit areas to safeguard the structures from water damage and uphold a safe and healthy environment for the animals. Moreover, these membranes possess resistance against various chemicals and can withstand harsh conditions, making them an excellent safeguard against potential chemical spills. All in all, waterproofing membranes are a highly suitable option for zoos or aquariums, as they offer an effective solution for preserving the integrity of the structures and habitats, averting water damage, and ensuring the safety and well-being of the animals.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Vehicular traffic areas can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier that prevents water from seeping through and causing damage to surfaces. In areas like parking decks or driveways, it is crucial to protect the underlying structure from water infiltration, which can lead to corrosion, deterioration, and expensive repairs. By utilizing a waterproofing membrane that is specifically designed for vehicular traffic, the surface can be effectively safeguarded from water damage, as well as other potential contaminants such as oil and chemicals. These membranes are typically more durable and capable of withstanding the weight and impact of vehicles, ensuring long-lasting protection. Furthermore, certain waterproofing membranes even offer slip-resistant properties, making them suitable for areas where vehicles require traction. Nevertheless, it is important to seek guidance from a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas, taking into account factors such as traffic volume, load capacity, and climate conditions.

- Q: Can a waterproofing membrane improve energy efficiency?

- Yes, a waterproofing membrane can improve energy efficiency. A waterproofing membrane acts as a barrier against moisture intrusion, preventing water from seeping into the building envelope. By keeping the structure dry, it helps to prevent the growth of mold and mildew, which can contribute to poor indoor air quality and the deterioration of building materials. In addition to protecting against moisture, a waterproofing membrane can also provide insulation benefits. Many waterproofing membranes are designed to have a high thermal resistance, or R-value. This means that they can provide an extra layer of insulation to the building, reducing heat transfer through the walls or roof. By improving the building's thermal performance, a waterproofing membrane can help to reduce the load on heating and cooling systems, resulting in energy savings and improved energy efficiency. Furthermore, a waterproofing membrane can also help to reduce air leakage in a building. Air leakage can account for a significant amount of energy loss, as conditioned air escapes through gaps and cracks in the building envelope. By sealing off these areas, a waterproofing membrane can help to improve the building's air tightness, reducing energy loss and improving energy efficiency. Overall, a waterproofing membrane can play a crucial role in improving energy efficiency by preventing moisture intrusion, providing additional insulation, and reducing air leakage. Investing in a high-quality waterproofing system can lead to long-term energy savings, improved indoor comfort, and a more sustainable and efficient building.

- Q: How to choose waterproof membrane

- Second, from the fetal base to identify the quality of the coil Generally from the product on the cross-section of visual inspection, the specific method can be purchased products by hand to tear it, observe the cross-section exposed fetal fiber, composite tires tear after the section of the grid cloth ribs exposed, this time It can be concluded that the product must be a composite tire coil, what kind of composite tire membrane with physical properties test - soluble content test to observe the exposed fetal base. And simple polyester tires, glass fiber tires after tearing the section only polyester or fiberglass fiber exposed.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate, which is the surface on which the membrane will be applied, needs to be clean, dry, and free from any contaminants or debris that could hinder the adhesion of the membrane. This usually involves removing any loose materials, such as old paint or sealants, and smoothing out any uneven surfaces. Additionally, it may be necessary to repair any cracks or damage in the substrate to ensure a proper and effective installation of the waterproofing membrane. Following the recommended preparation procedures will help to maximize the performance and durability of the membrane, ensuring its effectiveness in preventing water penetration and protecting the underlying structure.

- Q: Can a waterproofing membrane be used for swimming pool decks or patios?

- Yes, a waterproofing membrane can be used for swimming pool decks or patios.

Send your message to us

Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords