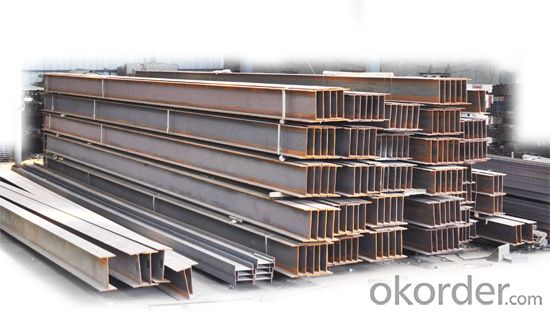

Steels Manufacture Building Material Construction on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | in bundles or as customer's requirement |

Delivery Detail: | Within 30days after receiving your deposit or copy of L/C |

2.Specifications

HRB400,HRB500 Steel Rebars

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

3.Product Description

Name | High Tensile Export Reinforcing Steel Bar ,Deformed Steel Bar ,HRB400B,HRB,46B,HRB500 Building Construction Material |

Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

Grade | A615 Gr40/60/75 BS 4449 Gr460,B500 GB HRB335,HRB400 ,HRB500

JIS G3112 SD390

|

Diameter | 6mm-40mm |

Length | 6-12m |

Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

Tolerance | As the standard or as your requirement |

Application | Building, construction, road, bridge,etc |

Certificated | BV |

MOQ | 500tons per size steel rebar |

Packing details | Steel rebar packed in bundle or as your requirement |

Delivery | Within 30 days after deposit |

Payment | T/T or L/C |

4.Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥470 | ≥14 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

≥500 | ≥630 | ≥12 | ||||||

5. Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

- Q: How are steel pipes classified based on their schedule?

- Steel pipes are classified based on their schedule, which refers to the wall thickness of the pipe. The schedule classification system includes different numbers such as 5, 10, 40, 80, etc., which indicate the thickness and strength of the steel pipe.

- Q: What are the safety considerations when working with steel pipes?

- There are several crucial safety considerations to bear in mind when working with steel pipes. To begin with, it is imperative to wear the appropriate personal protective equipment (PPE). This includes safety glasses or goggles to shield the eyes from debris or sparks, gloves to protect the hands from sharp edges or hot surfaces, and steel-toed boots to safeguard the feet from falling objects or heavy equipment. Additionally, it is advisable to wear a hard hat to shield the head from potential falling objects or hazards overhead. Moreover, one must be mindful of the weight and size of the steel pipes. Handling heavy pipes can strain the back and muscles, so it is essential to utilize proper lifting techniques and seek assistance when necessary. The use of lifting equipment, such as cranes or forklifts, can also help prevent injuries associated with heavy lifting. Another safety consideration is the risk of cuts or punctures. Steel pipes may have sharp edges or burrs, so it is important to handle them with care and wear suitable gloves to minimize the risk of injury. It is also recommended to inspect pipes for any defects or sharp edges before working with them. Furthermore, working with steel pipes may involve welding or cutting, which can generate sparks, heat, and fumes. It is vital to work in a well-ventilated area or employ proper ventilation equipment to ensure the elimination of harmful gases or fumes. Fire safety precautions, such as having fire extinguishers nearby and adhering to proper procedures for hot work, should also be taken. Lastly, one must be aware of potential hazards associated with working at heights or in confined spaces. When working on elevated platforms or scaffolding, fall protection measures, like safety harnesses or guardrails, should be in place. In confined spaces, proper ventilation and monitoring for hazardous gases are essential to prevent asphyxiation or exposure to toxic substances. By adhering to these safety considerations and following proper procedures, the risk of accidents or injuries when working with steel pipes can be significantly reduced.

- Q: Can steel pipes be recycled and used for other purposes?

- Yes, steel pipes can be recycled and used for other purposes. Steel is a highly recyclable material, and steel pipes are no exception. Recycling steel pipes helps to conserve natural resources and reduce the demand for new steel production. When steel pipes are recycled, they are typically sent to a recycling facility where they are sorted, cleaned, and processed. The pipes are then crushed into smaller pieces or melted down to be reshaped into new steel products. Recycled steel pipes can be used for a variety of purposes. They can be used in construction projects, such as for building bridges, roads, or buildings. They can also be used in the manufacturing of new steel products, such as automotive parts, appliances, or furniture. Additionally, recycled steel pipes can be used in the energy sector, for example, in the production of wind turbines or oil and gas pipelines. Using recycled steel pipes not only helps to reduce waste and conserve resources but also has environmental benefits. The recycling process requires less energy and produces fewer greenhouse gas emissions compared to the production of new steel. Therefore, recycling steel pipes is a sustainable option that contributes to a circular economy and helps to protect the environment.

- Q: How are steel pipes used in the construction of nuclear power plants?

- Steel pipes are used in the construction of nuclear power plants for various purposes, including transporting coolant, steam, and gases, as well as providing structural support for the overall system. These pipes are specifically designed to withstand high pressures, extreme temperatures, and corrosive environments, ensuring the safe and efficient operation of the nuclear power plant.

- Q: Can steel pipes be coated for aesthetic purposes?

- Yes, steel pipes can be coated for aesthetic purposes. Coating steel pipes not only adds a visually appealing finish but also provides protection against corrosion and other environmental factors. There are various coating options available for steel pipes, such as powder coating, epoxy coating, and vinyl coating, among others. These coatings can be applied in different colors and textures to enhance the appearance of the pipes and complement the surrounding environment. Whether in industrial settings, architectural projects, or decorative applications, coating steel pipes can transform them into visually appealing elements while maintaining their structural integrity.

- Q: How are steel pipes used in the marine industry?

- Steel pipes are commonly used in the marine industry for various applications such as shipbuilding, offshore oil and gas exploration, and marine infrastructure. They are utilized for constructing hulls, pipelines, and support structures due to their high strength, durability, and resistance to corrosion from seawater. Steel pipes also provide a reliable and efficient means of transporting fluids, gases, and other materials within marine vessels and structures.

- Q: How are steel pipes classified according to their use?

- Steel pipes can be classified according to their use into various categories such as structural pipes, plumbing pipes, oil and gas pipes, and industrial pipes.

- Q: Can steel pipes be used for conveying gases?

- Yes, steel pipes can be used for conveying gases. Steel pipes are widely used in industrial applications for transporting various gases, including natural gas, propane, and other types of gases. Steel pipes have excellent strength and durability, making them suitable for carrying gases at high pressures and temperatures. Additionally, steel pipes have a high resistance to corrosion, which is crucial when dealing with gases that can be corrosive.

- Q: Can steel pipes be used for gas transmission pipelines?

- Yes, steel pipes can be used for gas transmission pipelines. Steel pipes are commonly used in the construction of gas transmission pipelines due to their durability, strength, and resistance to corrosion. Additionally, steel pipes can withstand high pressure and extreme temperatures, making them suitable for the transportation of natural gas over long distances.

- Q: What are the advantages of using steel pipes over other materials like PVC or copper?

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes are incredibly durable and can withstand high pressure and extreme temperatures, making them suitable for various industrial applications. They are also resistant to corrosion, ensuring a longer lifespan compared to PVC or copper pipes. Additionally, steel pipes have excellent structural strength, providing enhanced stability and safety. They are also environmentally friendly as they can be recycled, reducing their impact on the environment. Overall, steel pipes offer superior strength, longevity, and reliability, making them a preferred choice for many industries.

Send your message to us

Steels Manufacture Building Material Construction on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords