Melt Extract Stainless Steel Fiber - End-Hooked Steel Fiber for Shotcrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

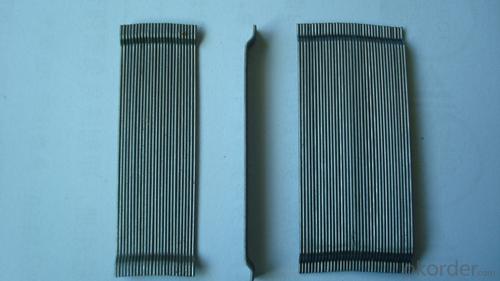

shape: glued together in a row

appearance: clear and bright

Product features

glued steel fiber together in a row ,is used with cement for construction

oncrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

Picture

Adhesion into a row

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

concrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

- Q: Can melt extract stainless steel fiber be used in sports field pavements?

- Yes, melt extract stainless steel fiber can be used in sports field pavements. Stainless steel fibers are known for their high strength and durability, making them an excellent choice for applications that require resistance to wear and heavy traffic, such as sports field pavements. These fibers can improve the overall performance and lifespan of the pavement by enhancing its toughness, crack resistance, and fatigue resistance. Additionally, the corrosion resistance of stainless steel ensures that the fibers will not deteriorate over time, even in harsh weather conditions. Overall, using melt extract stainless steel fiber in sports field pavements can help create a more robust and long-lasting surface that can withstand the rigorous demands of sports activities.

- Q: How does melt extract stainless steel fiber improve the toughness of fiber-reinforced shotcrete?

- Melt extract stainless steel fiber improves the toughness of fiber-reinforced shotcrete by providing enhanced crack resistance and increased ductility. The inclusion of these fibers in shotcrete helps to distribute and dissipate energy upon impact, reducing the propagation of cracks and enhancing the overall strength and durability of the material.

- Q: What is the recommended fiber geometry for melt extract stainless steel fiber in concrete?

- Typically, the preferred form of melt extract stainless steel fiber for concrete is straight, monofilament fibers. These fibers are generally slender, with a diameter ranging from 0.15 mm to 0.50 mm. While the length of the fibers can vary, it is often advised to use fibers measuring between 20 mm to 50 mm for optimal concrete performance. Using straight, monofilament fibers in concrete applications offers several advantages. Firstly, these fibers establish excellent bonding with the surrounding concrete matrix, enhancing the material's overall mechanical properties. Secondly, the straight geometry facilitates effective dispersion and distribution of the fibers throughout the concrete, ensuring uniform reinforcement and improved crack control. Furthermore, the slender diameter of the fibers enables easier mixing and placement of the concrete, with minimal impact on the mixture's workability. It is worth noting that the specific fiber geometry may differ depending on the desired performance requirements and the particular application of the concrete. Therefore, it is advisable to consult manufacturers or experts in the field to determine the most suitable fiber geometry for a specific project.

- Q: Can melt extract stainless steel fiber be used in the construction of airport runways?

- Yes, melt extract stainless steel fiber can be used in the construction of airport runways. Stainless steel fibers are commonly used in concrete reinforcement due to their high tensile strength, corrosion resistance, and durability. In the case of airport runways, where heavy loads and frequent aircraft traffic are expected, the addition of stainless steel fibers can enhance the strength and performance of the concrete pavement. The use of melt extract stainless steel fiber in airport runway construction offers several benefits. Firstly, these fibers help to control cracking in concrete, which is crucial for maintaining the integrity and longevity of the runway. By effectively distributing stress throughout the concrete, stainless steel fibers prevent the formation and propagation of cracks, minimizing the potential for spalling, erosion, and other forms of deterioration. Moreover, stainless steel fibers can improve the impact resistance and load-carrying capacity of airport runways. The fibers act as reinforcement, effectively increasing the tensile strength and flexural toughness of the concrete. This reinforcement is particularly important in areas with heavy aircraft traffic, where the runway is subjected to continuous stress and dynamic loads from landing and takeoff operations. Additionally, melt extract stainless steel fibers are highly resistant to corrosion, ensuring the long-term durability of the runway. Stainless steel is known for its ability to withstand harsh environmental conditions, including exposure to deicing salts and chemicals commonly used at airports. This corrosion resistance helps to maintain the structural integrity of the concrete pavement and reduces the need for costly repairs or replacements. In summary, melt extract stainless steel fiber can be successfully utilized in the construction of airport runways. Its ability to control cracking, enhance load-bearing capacity, and resist corrosion makes it an excellent choice for reinforcing the concrete pavement in areas that require high durability and strength, such as airport runways.

- Q: Does melt extract stainless steel fiber improve the resistance to carbonation in shotcrete?

- Yes, melt extract stainless steel fiber can improve the resistance to carbonation in shotcrete. Carbonation is a process in which carbon dioxide from the atmosphere penetrates into concrete or shotcrete, causing a chemical reaction that reduces the alkalinity of the material. This carbonation process can lead to the corrosion of steel reinforcement within the shotcrete, reducing its structural integrity and durability. By adding melt extract stainless steel fiber to shotcrete, the resistance to carbonation can be enhanced. Stainless steel fibers have a high resistance to corrosion, making them ideal for enhancing the durability of shotcrete in harsh environments. These fibers create a three-dimensional reinforcement network within the shotcrete, increasing its resistance to cracking and minimizing the potential for carbon dioxide penetration. Additionally, the presence of stainless steel fibers can improve the overall mechanical properties of shotcrete, including its tensile strength and toughness. This increased strength and durability can further enhance the resistance to carbonation, as the shotcrete is better able to withstand external factors that may contribute to degradation. It is important to note that while melt extract stainless steel fiber can improve the resistance to carbonation in shotcrete, it is not a standalone solution. Proper concrete mix design, placement techniques, and curing methods are also crucial in maximizing the resistance to carbonation. Nonetheless, the addition of stainless steel fibers is a valuable tool in enhancing the durability and longevity of shotcrete in carbonation-prone environments.

- Q: Can melt extract stainless steel fiber be used in lightweight or low-density concrete?

- Yes, melt extract stainless steel fiber can be used in lightweight or low-density concrete.

- Q: Can melt extract stainless steel fiber be used in architectural concrete applications?

- Yes, melt extract stainless steel fiber can be used in architectural concrete applications.

- Q: Can melt extract stainless steel fiber be used in the construction of railway tunnels?

- Melt extract stainless steel fiber is indeed applicable for the construction of railway tunnels. Its commendable attributes of high strength, durability, and corrosion resistance make it a favorable choice for a range of construction purposes, including railway tunnels. Implementing stainless steel fiber in tunnel construction contributes to the overall structural integrity and durability of the tunnels. By reinforcing the concrete utilized in the tunnel lining, it provides heightened crack resistance and an improved load-bearing capacity. Moreover, stainless steel fibers offer exceptional fire resistance properties, which are essential for ensuring the safety of railway tunnels. Hence, melt extract stainless steel fiber serves as a suitable material for constructing railway tunnels.

- Q: How does melt extract stainless steel fiber enhance the fatigue resistance of concrete?

- Concrete's fatigue resistance can be enhanced by adding melt extract stainless steel fiber. This reinforcement improves the structural integrity of the concrete and provides additional strength. The fibers create a three-dimensional network that helps distribute stress and load, acting as a barrier to crack propagation and preventing the formation and growth of micro-cracks that can lead to fatigue failure. The high tensile strength and ductility of stainless steel fibers allow them to effectively absorb and disperse energy during cyclic loading, reducing stress concentration at potential crack initiation points. This significantly improves the fatigue life of the concrete by preventing crack development and extending the overall durability and lifespan of the structure. In addition, the corrosion resistance of stainless steel fibers is crucial for enhancing concrete's fatigue resistance. Unlike other fibers, stainless steel fibers are not affected by corrosion from moisture, chemicals, or environmental factors. This ensures that the fibers remain effective and intact over time, even in harsh conditions, further enhancing the concrete's fatigue resistance. Overall, the inclusion of melt extract stainless steel fibers in concrete enhances its fatigue resistance by providing additional reinforcement, reducing crack propagation, absorbing and dispersing energy, and improving its durability and corrosion resistance. This results in a more resilient and long-lasting concrete structure, especially in applications subjected to cyclic loading and fatigue stress.

- Q: Does melt extract stainless steel fiber improve the resistance to chemical attack in concrete?

- Indeed, the incorporation of melt extract stainless steel fiber in concrete leads to an enhancement in its resistance against chemical attack. Renowned for their exceptional resistance to corrosion and ability to endure chemical exposure, stainless steel fibers create a safeguarding shield upon their introduction into the concrete mixture. This shield effectively obstructs the infiltration of chemicals into the concrete matrix, consequently bolstering the durability and lifespan of the concrete structure, particularly in environments where chemical attack poses a concern, such as wastewater treatment plants, chemical processing facilities, and industrial areas. By employing melt extract stainless steel fiber, the risk of chemical degradation can be significantly diminished, while concurrently augmenting the overall resistance against chemical attack.

Send your message to us

Melt Extract Stainless Steel Fiber - End-Hooked Steel Fiber for Shotcrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords