Steel Fiber Straight Type CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

The raw material is stainless steel ingots, using electric stoves which melt the stainless steel ingots to become 1500 ~ 1600 ℃ steel liquid, and then with a grooved high speed rotating melt-extracting steel wheel which produces wires that meets are our customers’ specific requirements. When melting down to a wheel steel liquid surface, the liquid steel blow out by slot with centrifugal force at extremely high speed with cooling forming. Melting wheels with water keep the cooling speed. This method is done to produce different material, different sizes of steel fiber.

| SIZE | CHEMIC ELEMENT(%) | ||||||

| C | P | Mn | Si | Cr | Ni | Al | |

| AISI330 | ≤0.40 | ≤0.04 | ≤2.00 | ≤0.75 | 17~20 | 33~37 | |

| AISI310 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.50 | 24~26 | 19~22 | |

| AISI316 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.00 | 16~18 | 10~14 | |

| AISI314 | ≤0.40 | ≤0.045 | ≤2.00 | 1.5-3.0 | 23~26 | 19~22 | |

| AISI309 | ≤0.40 | ≤0.04 | ≤2.00 | ≤1.00 | 22~24 | 12~15 | |

| AISI304 | ≤0.40 | ≤0.04 | ≤2.00 | ≤2.00 | 18~20 | 8~10 | |

| AISI301 | ≤0.40 | ≤0.04 | ≤2.00 | ≤2.00 | 16~18 | 6~8 | |

| AISI201 | ≤0.40 | ≤0.06 | 5.5~7.5 | ≤1.00 | 16~18 | 3.5~5.5 | |

| AISI446 | ≤0.40 | ≤0.04 | ≤1.50 | ≤2.00 | 23~27 | ||

| AISI430 | ≤0.40 | ≤0.03 | ≤1.00 | ≤2.00 | 16~18 | ||

| NAS430A | ≤0.40 | ≤0.03 | ≤0.50 | ≤0.50 | 16~18 | 2~4 | |

| SIZE(mm) | ||||

| length | 20 | 25 | 30 | 35 |

| width | 0.75~1.5 | 0.75~1.5 | 0.75~1.5 | 0.75~1.5 |

| thickness | 0.2~0.75 | 0.2~0.75 | 0.2~0.75 | 0.2~0.75 |

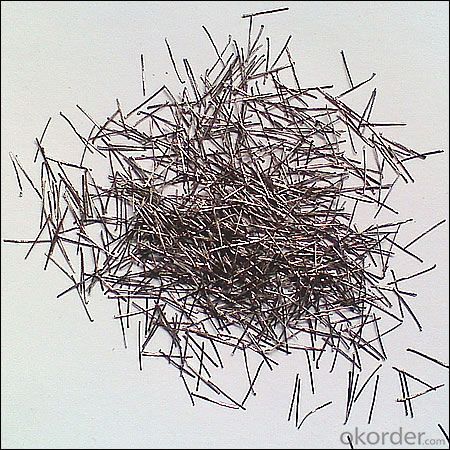

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

- Q: Does melt extract stainless steel fiber enhance the crack resistance of concrete?

- Yes, melt extract stainless steel fiber does enhance the crack resistance of concrete. Stainless steel fibers are added to concrete mixes to improve its tensile strength and prevent the formation and propagation of cracks. The melt extract stainless steel fibers act as reinforcement within the concrete matrix, providing additional strength and durability. When properly dispersed throughout the concrete, these fibers create a three-dimensional network that helps distribute stress and load more evenly. This reduces the likelihood of cracks forming and spreading, and enhances the overall crack resistance of the concrete. Melt extract stainless steel fibers also have a high melting point and excellent corrosion resistance, making them particularly effective in harsh environments or when exposed to chemicals. These fibers can withstand high temperatures and prevent the concrete from spalling or cracking under extreme conditions. Furthermore, the addition of stainless steel fibers can improve the impact resistance and flexural strength of concrete, making it more resistant to cracking caused by external forces or dynamic loads. In conclusion, melt extract stainless steel fiber does enhance the crack resistance of concrete by reinforcing the material and improving its tensile strength. This results in a more durable and long-lasting concrete structure.

- Q: Are there any guidelines or standards for using melt extract stainless steel fiber in construction?

- Yes, there are guidelines and standards for using melt extract stainless steel fiber in construction. The main standard that governs the use of stainless steel fiber in construction is ASTM A820. This standard provides guidelines for the classification, chemical composition, and mechanical properties of stainless steel fibers used in concrete reinforcement. According to ASTM A820, stainless steel fibers must meet specific requirements in terms of diameter, length, and tensile strength. The standard also specifies the minimum fiber content that should be added to concrete to achieve the desired reinforcement effect. In addition to ASTM A820, there are also other guidelines and standards that provide recommendations for the use of stainless steel fiber in specific applications. For example, the American Concrete Institute (ACI) provides guidelines on the use of stainless steel fiber reinforcement in shotcrete and precast concrete elements. It is important to note that while these guidelines and standards provide useful recommendations, they are not mandatory requirements. The specific requirements for using melt extract stainless steel fiber in construction may vary depending on the project specifications and local building codes. Therefore, it is always recommended to consult with design professionals and local authorities to ensure compliance with the appropriate guidelines and standards.

- Q: Can melt extract stainless steel fiber be used in the construction of precast concrete walls?

- Yes, melt extract stainless steel fiber can be used in the construction of precast concrete walls. These fibers can enhance the strength and durability of the concrete, reduce cracking, and improve the overall performance of the precast walls.

- Q: How does the addition of melt extract stainless steel fiber affect the fire resistance of concrete?

- The addition of melt extract stainless steel fiber significantly enhances the fire resistance of concrete. Stainless steel fibers are known for their exceptional heat resistance, which makes them suitable for use in high-temperature applications such as fire-resistant concrete. When incorporated into concrete, these fibers create a three-dimensional matrix that improves the overall performance and durability of the material under fire conditions. The presence of stainless steel fibers in concrete helps to prevent crack propagation and spalling during exposure to high temperatures. This is because the fibers effectively absorb and distribute the heat, reducing the thermal stresses on the concrete. As a result, the concrete maintains its structural integrity for a longer duration, even when subjected to extreme heat. Moreover, stainless steel fibers enhance the fire resistance of concrete by improving its thermal conductivity. The fibers act as a heat sink, absorbing and dissipating heat more efficiently compared to conventional concrete. This property helps to slow down the temperature rise within the concrete, delaying the onset of thermal degradation and extending the fire resistance of the material. Additionally, melt extract stainless steel fibers also provide reinforcement to the concrete, enhancing its overall strength and impact resistance. This reinforcement further contributes to the fire resistance of the concrete by preventing its premature failure or collapse during a fire event. In summary, the addition of melt extract stainless steel fiber to concrete greatly improves its fire resistance. The fibers act as a heat sink, distribute heat more uniformly, and enhance the structural integrity of the material under high-temperature conditions. Consequently, the use of stainless steel fibers in concrete can significantly prolong the duration for which the material can withstand fire, providing an added layer of safety and protection in fire-prone environments.

- Q: How does melt extract stainless steel fiber improve the toughness of high-performance concrete?

- Melt extract stainless steel fiber improves the toughness of high-performance concrete through several key mechanisms. Firstly, the addition of stainless steel fibers enhances the crack resistance of the concrete. When the concrete is subjected to stress or loading, the fibers act as reinforcement and help to prevent the propagation of cracks. This results in a more durable and resilient material that can withstand higher levels of stress without significant damage. Secondly, the stainless steel fibers also improve the post-crack behavior of the concrete. Once cracks start to develop, the fibers distribute the stress more evenly throughout the material, effectively dissipating the energy and preventing further crack growth. This ensures that the concrete maintains its structural integrity even after the initiation of cracks, thereby enhancing its overall toughness. Furthermore, the addition of melt extract stainless steel fibers can also enhance the flexural strength of high-performance concrete. The fibers act as reinforcement within the matrix, increasing the tensile strength and preventing the concrete from undergoing excessive deflection or failure under bending loads. This is particularly important in applications where high-performance concrete is exposed to dynamic or impact loading. Moreover, the stainless steel fibers also improve the resistance of high-performance concrete to shrinkage and thermal cracking. Due to their high melting point and low coefficient of thermal expansion, these fibers provide enhanced dimensional stability to the concrete, reducing the risk of cracking caused by temperature variations or drying shrinkage. In summary, melt extract stainless steel fiber improves the toughness of high-performance concrete by enhancing crack resistance, improving post-crack behavior, increasing flexural strength, and reducing the risk of shrinkage and thermal cracking. These properties make high-performance concrete with stainless steel fibers an ideal choice for structures that require durability, resistance to cracking, and the ability to withstand high levels of stress and loading.

- Q: Can melt extract stainless steel fiber be used in pre-stressed concrete applications?

- Yes, melt extract stainless steel fiber can be used in pre-stressed concrete applications. The high tensile strength and corrosion resistance of stainless steel fibers make them suitable for reinforcing concrete structures that are subjected to pre-stressing forces. These fibers can enhance the durability and structural integrity of pre-stressed concrete elements, providing additional strength and preventing cracking or failure under tension.

- Q: Does melt extract stainless steel fiber affect the workability of concrete?

- Indeed, the inclusion of melt extract stainless steel fiber in concrete can have an impact on its workability. Incorporating these stainless steel fibers into the concrete mixture can augment its viscosity and rigidity, thereby complicating the process of manipulation. Consequently, the workability of the concrete may be compromised, rendering it less fluid and more challenging to shape or mold. Nonetheless, the severity of this influence hinges upon the quantity and length of the stainless steel fibers employed, as well as the specific necessities of the concrete application.

- Q: Does melt extract stainless steel fiber improve the fire resistance of reinforced concrete slabs?

- Yes, melt extract stainless steel fiber does improve the fire resistance of reinforced concrete slabs. The addition of stainless steel fibers enhances the structural integrity and thermal properties of the concrete, making it more resistant to high temperatures and preventing rapid failure or collapse during a fire.

- Q: What is the effect of melt extract stainless steel fiber on the durability of shotcrete?

- The use of melt extract stainless steel fiber in shotcrete can greatly enhance its durability. Shotcrete is a popular construction material that is typically sprayed onto surfaces, providing a strong and durable concrete layer. However, shotcrete can be prone to cracking and spalling over time, especially in harsh environmental conditions or under heavy loading. By incorporating melt extract stainless steel fiber into the shotcrete mix, the overall durability of the material is significantly improved. These fibers act as reinforcement, providing added strength and crack resistance to the shotcrete. The stainless steel fibers help to distribute stress and prevent the formation and propagation of cracks, thus enhancing the overall durability and lifespan of the shotcrete. The unique properties of melt extract stainless steel fibers make them ideal for shotcrete applications. They have high tensile strength, which allows them to effectively resist crack formation and propagation. Additionally, stainless steel fibers exhibit excellent corrosion resistance, even in aggressive environments, further enhancing the durability of the shotcrete. The addition of melt extract stainless steel fibers also improves the overall structural integrity of shotcrete. The fibers help to increase the flexural and shear strength of the material, making it more resistant to loading and impact forces. This enhanced structural integrity ensures that the shotcrete can withstand heavy loads, vibrations, and other external forces without significant damage or degradation. Overall, the incorporation of melt extract stainless steel fiber in shotcrete significantly improves its durability by enhancing crack resistance, corrosion resistance, and structural integrity. This results in a longer lifespan and reduced maintenance requirements for shotcrete structures, making it a highly beneficial addition to the construction industry.

- Q: Is melt extract stainless steel fiber compatible with all types of concrete finishing techniques?

- Different concrete finishing techniques may not be compatible with melt extract stainless steel fiber. The compatibility of the fiber with various finishing techniques depends on factors such as the type of concrete mix, desired finish, and project requirements. Melt extract stainless steel fiber is commonly utilized in concrete to enhance durability, strength, and resistance to cracking. However, adding fiber to the concrete mix can impact its workability and finishing characteristics. Certain finishing techniques, like troweling or burnishing, may pose challenges when using concrete with stainless steel fibers. The presence of fibers can cause surface irregularities or make the trowel bounce, making it difficult to achieve a smooth and consistent finish. On the other hand, other finishing techniques like broom or brush finishing may be more suitable for concrete with stainless steel fibers. These techniques can improve the bond between the fiber and the concrete and create a textured finish. To determine the compatibility of melt extract stainless steel fiber with specific finishing techniques, it is essential to consult with a concrete professional or manufacturer. They can offer guidance based on the project requirements and recommend the most appropriate finishing technique to achieve the desired results.

Send your message to us

Steel Fiber Straight Type CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords