Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

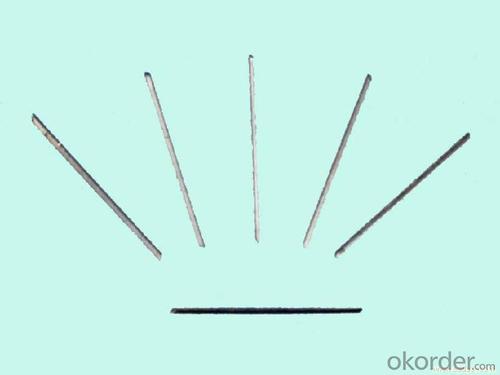

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the plastic settlement of concrete?

- The use of melt extract stainless steel fiber in concrete has a positive effect on reducing the plastic settlement of the material. The addition of stainless steel fibers helps to improve the overall performance and durability of the concrete by enhancing its resistance to cracking and shrinkage. When concrete is in its plastic state, it is vulnerable to settlement due to its high water content and the effects of gravity. This settlement can result in an uneven and weakened surface, compromising the structural integrity of the concrete. However, by incorporating melt extract stainless steel fibers into the mix, the fibers act as reinforcement, providing an effective mechanism to counteract plastic settlement. The stainless steel fibers help to distribute the stress and load evenly throughout the concrete, preventing concentrated settlement in specific areas. This even distribution improves the overall homogeneity and stability of the concrete, reducing the risk of cracking and surface deformations. Furthermore, melt extract stainless steel fibers have a high aspect ratio and excellent bonding properties with the cement matrix. This ensures that the fibers are well dispersed and securely anchored within the concrete, enhancing their ability to resist plastic shrinkage and settlement. Overall, the incorporation of melt extract stainless steel fibers in concrete significantly reduces the plastic settlement, improving the overall quality and longevity of the material. This leads to a more durable and structurally sound concrete that can withstand various external factors, such as load, temperature changes, and environmental conditions.

- Q: What are the main points of construction of steel fiber reinforced concrete?

- About the construction points of steel fiber reinforced concrete, roughly speaking from the following five aspects:1. steel fiber dispersion deviceFirst, the steel fiber shall be taken into and dispersed. By dispersing device device into a stirrer. By dispersing device can avoid the agglomeration phenomenon. Other materials and engineering should be required in the uniform mixing of steel fiber into a blender.

- Q: Can melt extract stainless steel fiber be used in underground mining applications?

- Yes, melt extract stainless steel fiber can be used in underground mining applications. It is commonly used for reinforcement purposes in concrete and other construction materials. Its high strength and resistance to corrosion make it suitable for the demanding conditions found in underground mining.

- Q: Can melt extract stainless steel fiber be used in shotcrete tunnel boring machine applications?

- Yes, melt extract stainless steel fiber can be used in shotcrete tunnel boring machine applications. Shotcrete is a method of applying concrete or mortar using a high-pressure hose, and the addition of stainless steel fiber can enhance the mechanical properties and durability of the shotcrete. The melt extract stainless steel fiber is made from stainless steel through a melting and extraction process, resulting in a high-strength fiber with excellent corrosion resistance. These properties make it suitable for use in tunnel boring machine applications where the shotcrete needs to withstand high pressures, vibrations, and potential exposure to moisture or chemicals. Additionally, the stainless steel fiber can improve the flexural and tensile strength of the shotcrete, reducing the risk of cracking and enhancing the overall stability and performance of the tunnel structure.

- Q: I want 10 tons of steel fiber, urgently, where can quickly supply

- Your dosage is how big, general steel fiber is according to the dosage, the dosage is big, can be cheaper

- Q: How does melt extract stainless steel fiber improve the durability of tunnel linings?

- Melt extract stainless steel fiber improves the durability of tunnel linings by reinforcing the concrete matrix. The fibers act as a secondary reinforcement, enhancing the strength and impact resistance of the lining. This results in a more robust structure that can better withstand the stress and strain of tunneling operations, reducing the risk of cracking, spalling, and long-term degradation.

- Q: How does melt extract stainless steel fiber affect the resistance of concrete to sulfate attack?

- Melt extract stainless steel fiber improves the resistance of concrete to sulfate attack by enhancing the overall durability and preventing the ingress of sulfate ions into the concrete matrix. The presence of stainless steel fiber forms a protective barrier that hinders the penetration of sulfates, reducing the risk of concrete deterioration caused by sulfate attack.

- Q: What is the effect of melt extract stainless steel fiber on the autogenous shrinkage of concrete?

- The addition of melt extract stainless steel fibers to concrete can significantly reduce the autogenous shrinkage. These fibers act as reinforcement, helping to distribute the internal stresses and restrain the shrinkage of the concrete. This leads to a decrease in the overall shrinkage of the concrete, resulting in improved durability and reduced cracking potential.

- Q: Is melt extract stainless steel fiber compatible with different types of curing methods?

- Different types of curing methods are compatible with melt extract stainless steel fiber. This fiber is made to improve the durability and performance of concrete in different applications, both wet and dry curing methods. It can endure high temperatures during curing without compromising its structure or causing any negative effects on the concrete. Moreover, melt extract stainless steel fiber can be utilized alongside various curing methods like steam curing, water curing, and air curing, allowing for versatility and suitability with diverse project needs.

- Q: What is the effect of melt extract stainless steel fiber on the cracking behavior of concrete?

- The effect of melt extract stainless steel fiber on the cracking behavior of concrete is generally positive. When added to concrete mixtures, stainless steel fibers can enhance the overall performance and durability of the concrete by reducing cracking. The incorporation of melt extract stainless steel fibers into concrete helps to improve the tensile strength and ductility of the material. As a result, it enhances the concrete's resistance to cracking under different types of loading, such as shrinkage, thermal expansion, and external forces. Stainless steel fibers act as reinforcement within the concrete matrix, effectively bridging any cracks that may occur. This bridging effect helps to prevent the propagation of cracks, limiting their size and minimizing the potential for further damage. It also increases the overall toughness and energy absorption capacity of the concrete. Furthermore, melt extract stainless steel fibers can also improve the overall durability of concrete by reducing the likelihood of corrosion. Stainless steel is highly resistant to corrosion, even in harsh environments, which helps to protect the concrete from degradation and prolong its service life. Overall, the addition of melt extract stainless steel fibers to concrete can significantly improve its cracking behavior. By enhancing tensile strength, ductility, and durability, these fibers contribute to a more robust and long-lasting concrete structure.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber by CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords