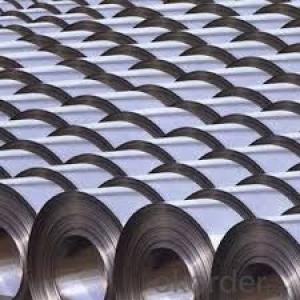

Steel sheets for sale hot rolled different grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14549 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-rolling mill: Equipment on which solidified steel preheated to a high temperature is continuously rolled between two rotating cylinders.

These products are suitable for a wide range of applications, from formable quality to specific

strength requirement in material. SABIC can supply Hot Rolled Coils as Mill Edged, Side Trim Edged,

Slit, Skin Passed, Chequered and Pickled Coils.

Standard and Grade :

Hot rolled steel coils | ||||

JIS | ASTM | SAE | EN | |

Commercial quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A,B,C | 1006~1025 |

10111 DD11 |

Drawing quality | G3131 SPHD | 1006~1010 | 10111 DD12 | |

Deep drawing quality | G3131 SPHE | A622 A1011 DS Type A,B | 1006~1010 | 10111 DD13 DD14 |

General structure (T.S.<490N/MM2) | G3101 SS330 SS440 G3106 SM400A G3132 SPHT1 SPTT2 SPHT3 | A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 | |

General structure (T.S.≥490N/MM2) | G3101 SS490 G3106 SM490A SM490YA | A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45,50 |

J1392 050X | |

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

(1) We cooperate with famousfactories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we

can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all

our key markets. To maintain our position as market leader we must continue to

add value in all that we do.

FAQ:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw

material to final product we have strict quality test;We resolutely put an end to unqualified products

flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the thickness of the paint board?

- Paint boards are generally used in cabinets or doors and other places, we have often seen, but also understand some of the paint plate thickness of how much better? Paint board is a kind of woodworking materials. It is based on density board as base material, the surface after six to nine times (not the same as the number of Polish manufacturers are different, the more the number of process requirements is high, the cost is higher), the primer, drying, polishing (at the end of three, two, light) high temperature baked. At present, mainly used in cabinets, doors and so on. Paint board can be divided into light, Matt and metal paint three. At present, there are the latest engraving baking paint board, Newcastle house paint baking board and so on.

- Q: Can steel sheets be used for interior design purposes?

- Indeed, interior design purposes can indeed utilize steel sheets. With their sleek and modern appearance, steel sheets possess the ability to infuse an industrial or contemporary touch to any interior space. Moreover, their durability, longevity, and resistance to wear and tear render them highly suitable for areas with heavy foot traffic. In the realm of interior design, steel sheets can be employed in a myriad of ways, including but not limited to wall cladding, ceiling panels, room dividers, furniture, countertops, and backsplashes. Additionally, they can be painted or coated with diverse finishes to perfectly complement the desired aesthetic, while also being malleable or perforated to create one-of-a-kind patterns or textures. All in all, by offering versatility, strength, and an aesthetically pleasing element, steel sheets serve as a valuable asset in interior design endeavors.

- Q: Can steel sheets be used for heat exchangers or boilers?

- Yes, steel sheets can be used for heat exchangers or boilers. Steel is a commonly used material in the construction of heat exchangers and boilers due to its high strength, durability, and resistance to corrosion at high temperatures. Additionally, steel sheets can be easily formed and welded to create the required shapes and structures for efficient heat transfer.

- Q: What are the different grades of steel used for making sheets?

- The different grades of steel used for making sheets vary depending on the specific application and requirements. Some common grades include mild steel, stainless steel, high-strength low-alloy (HSLA) steel, and galvanized steel. Each grade has distinct properties such as strength, corrosion resistance, and formability, which make them suitable for different purposes in various industries.

- Q: Are steel sheets resistant to UV rays?

- Steel sheets do not possess inherent resistance to UV rays, contrary to belief. UV damage can indeed affect steel, leading to fading, discoloration, or even corrosion with the passage of time. However, the degree of harm incurred is contingent upon several factors, including the steel type, sheet thickness, UV exposure specifics, and presence of protective coatings. In order to bolster the UV resistance of steel sheets, manufacturers commonly administer coatings like paint, powder coatings, or galvanized finishes, which offer some level of defense against UV rays. It is vital to consult steel suppliers or manufacturers to ascertain the precise UV resistance capabilities of the steel sheets in use and consider supplementary protective measures if deemed necessary.

- Q: Can steel sheets be used for wall cladding?

- Yes, steel sheets can be used for wall cladding. Steel is a highly versatile and durable material that can be used in various applications, including wall cladding. Steel sheets provide excellent structural support, weather resistance, and aesthetic appeal. They are commonly used in commercial and industrial buildings, as well as residential properties, to enhance the appearance and protect the underlying structure. Steel sheets can be customized to fit specific design requirements and are available in a variety of finishes, textures, and colors, making them a popular choice for wall cladding. Additionally, steel cladding offers several benefits such as fire resistance, low maintenance, and long-lasting performance, making it an ideal option for wall cladding in different environments.

- Q: Can steel sheets be used for electrical transformers?

- No, steel sheets cannot be used for electrical transformers as they do not possess the necessary magnetic properties required for efficient transformer operation. Laminated iron cores are typically used in transformers to minimize energy losses and ensure proper magnetic flux.

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a commonly used material due to its durability, strength, and ability to provide electromagnetic shielding. It is suitable for protecting electrical components from external factors such as moisture, dust, and impact while also providing a safe and secure environment for the electrical equipment.

- Q: What is the difference between hot-rolled and cold-rolled steel sheets?

- The main difference between hot-rolled and cold-rolled steel sheets lies in the manufacturing process and the resulting characteristics of the steel. Hot-rolled steel sheets are made by heating a large steel slab and passing it through rollers at high temperatures. This process allows the steel to be easily shaped and formed into various sizes and thicknesses. The high temperature also helps to eliminate any residual stress within the steel, making it more ductile and malleable. As a result, hot-rolled steel sheets have a rougher surface finish and may have some scale, which is a thin oxide layer on the surface. However, they also tend to be less expensive and have a wider range of available sizes. On the other hand, cold-rolled steel sheets are made by cooling down the hot-rolled steel and passing it through rollers at room temperature. This process not only reduces the thickness of the steel but also improves its surface finish and dimensional accuracy. Cold-rolling imparts a smooth and shiny appearance to the steel sheets, making them ideal for applications where aesthetics are important. Additionally, the cold-rolling process increases the strength and hardness of the steel, making it more suitable for high-stress applications. However, the cold-rolled steel sheets are generally more expensive due to the additional processing involved. In summary, hot-rolled steel sheets offer better formability and lower cost, but have a rougher surface finish and may have some scale. Cold-rolled steel sheets, on the other hand, have superior surface finish, dimensional accuracy, and strength, but are more expensive. The choice between hot-rolled and cold-rolled steel sheets depends on the specific requirements of the application, including the desired surface finish, strength, and cost considerations.

- Q: Can steel sheets be used for reinforcing concrete structures?

- Yes, steel sheets can be used for reinforcing concrete structures. Steel sheets, commonly referred to as steel plates or steel mesh, are often used as reinforcement in concrete structures to enhance their tensile strength and durability. The steel sheets are typically placed within the concrete to provide additional support, preventing cracking and increasing the overall structural integrity of the concrete.

Send your message to us

Steel sheets for sale hot rolled different grade

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 14549 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords